Sludge calorific value conditioning machine

A conditioning machine and calorific value technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, water/sewage treatment, etc., can solve high treatment cost, high noise, drying efficiency, and demand The factors affecting the natural conditions of the site and other issues have achieved the effect of low flatness requirements for the turntable, scientific and reasonable structure, and maintaining the calorific value of the sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

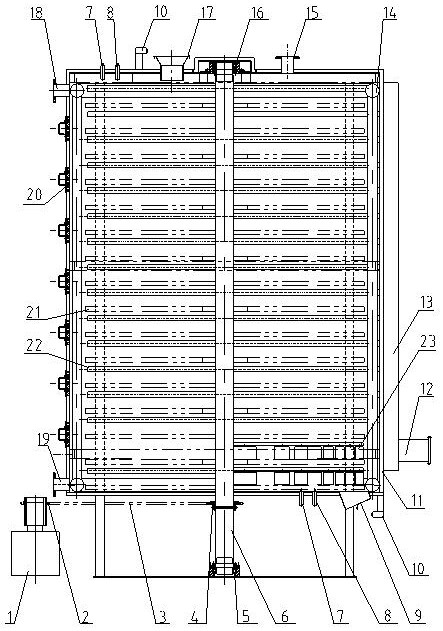

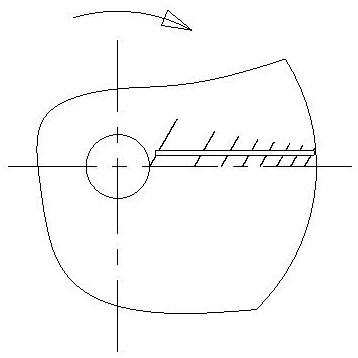

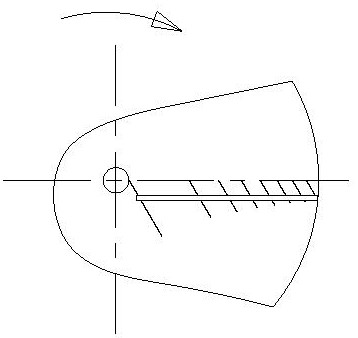

[0032] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a sludge calorific value conditioning machine, including a frame 11 and a geared motor 1 installed on one side thereof, the frame 11 is composed of a bracket and an inner and outer stainless steel shell, and an insulating layer is sandwiched in the middle. For the fixing and supporting function of the whole equipment, the first sprocket 2 is sleeved on the output shaft of the reduction motor 1, and the central shaft 6 is embedded in the center of the frame 11, and the bottom end of the central shaft 6 is socketed at the connection point of the frame 11. The lower beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com