Low-carbon environment-friendly fuel oil for boiler and preparation method thereof

A low-carbon, environmentally friendly, fuel oil technology, applied in the direction of liquid carbon-containing fuels, fuels, fuel additives, etc., can solve the problems of insufficient combustion, low thermal efficiency, large flow rate, etc., and achieves reduction of free carbon deposition, environmental protection, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

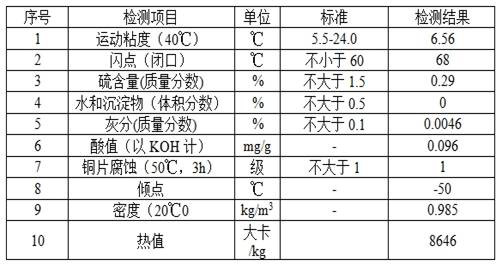

[0014] Example 1 A low-carbon environment-friendly boiler fuel oil and its performance index test.

[0015] A low-carbon environment-friendly fuel oil for boilers is composed of the following raw materials in parts by weight: 65 parts of diesel oil, 0.4 parts of polyvinyl alcohol, 0.5 parts of sorbitol fat, 0.1 part of fatty alcohol polyoxyethylene ether, 35 parts of water, stearin Acid alkanolamide 0.05 part.

[0016] A method for preparing fuel oil for low-carbon environment-friendly boilers specifically includes the following steps.

[0017] Step 1. Weigh the required raw materials in proportion for later use.

[0018] Step 2. Add water to the stirring tank A, add polyvinyl alcohol to stir when heated to about 4°C, heat to 55-58°C to dissolve the polyvinyl alcohol; then add sorbitol fat and fatty alcohol polyoxyethylene ether to stir for 10 -20 minutes; then add the additive stearic acid alkanolamide, when the temperature in the stirring tank is 58-60°C, add diesel oil, k...

Embodiment 2

[0023] Example 2 The fuel oil boiler prepared in Example 1 is used for exhaust gas detection.

[0024] Liaoning North Environmental Testing Technology Co., Ltd. tested the waste of boilers using the diesel fuel oil prepared in Example 1 according to relevant environmental protection standards and technical specifications.

[0025] 1. Overview of the boiler.

[0026] Model: CDZS1.4-85 / 60 / Q(Y).

[0027] Manufacturer: Liaoyang Xinao Environmental Protection Boiler Co., Ltd.

[0028] Fuel type: microemulsion composite fuel.

[0029] Rated power: 1.4MW.

[0030] Launch date: November 2011.

[0031] Chimney height: 14 meters.

[0032] 2. Implementation of standards and technical specifications.

[0033] (1) GB / T16157-1996>.

[0034] (2) GB 5468-91>.

[0035] (3) HJ / T 397-2007 >.

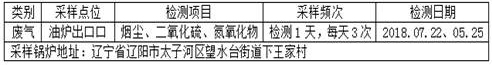

[0036] 3. Sampling point and frequency.

[0037] Table 2. Sampling points, detection items and frequency.

[0038]

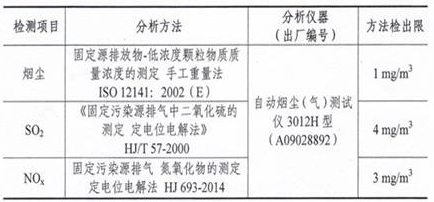

[0039] 4. Test items, analytical methods, analytical instruments and metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com