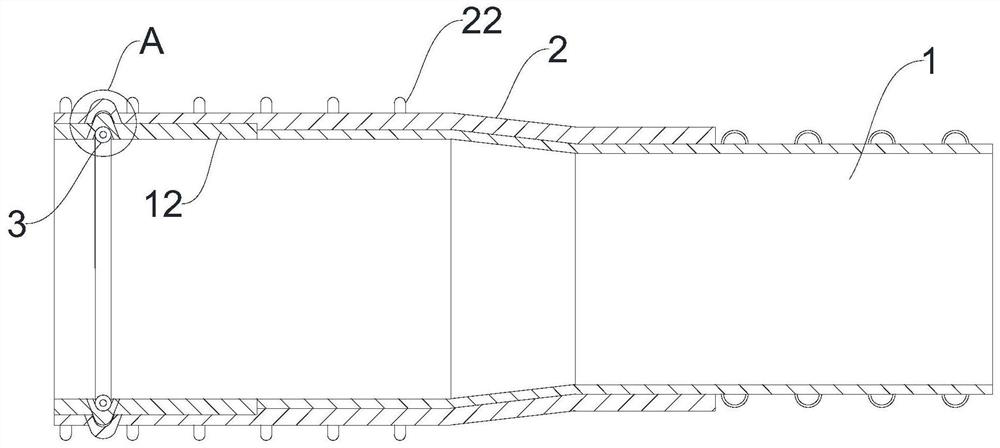

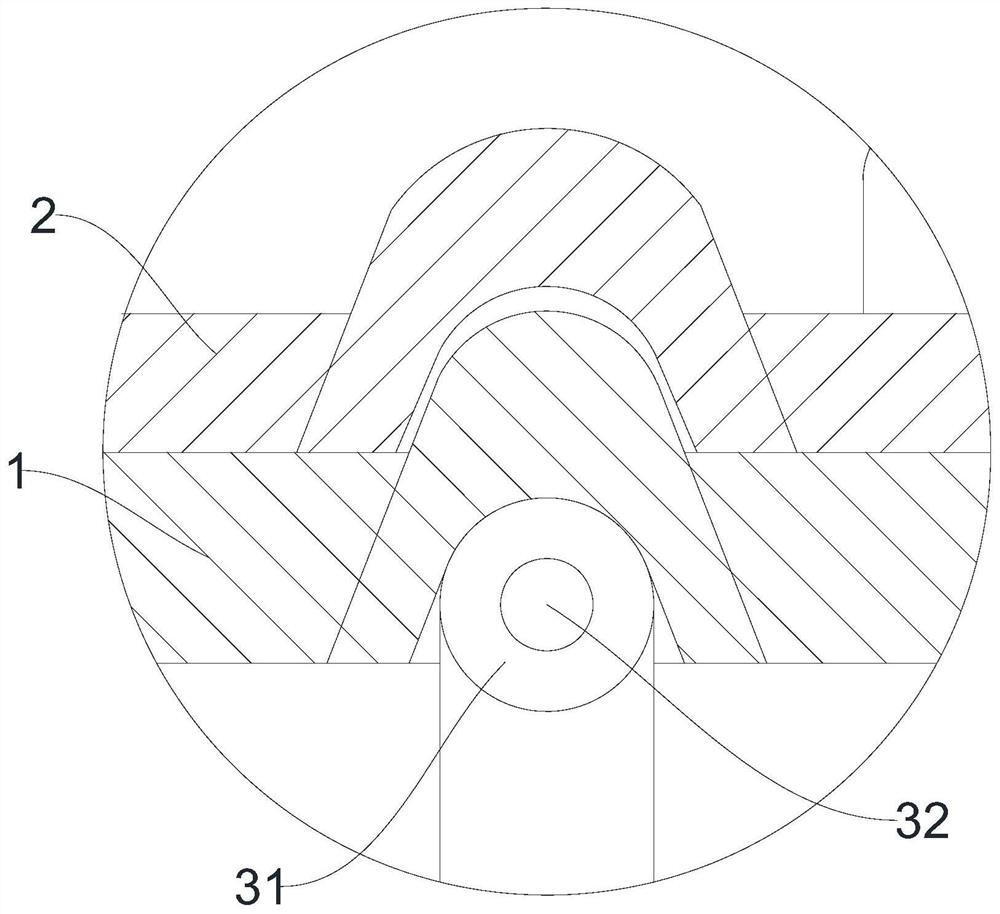

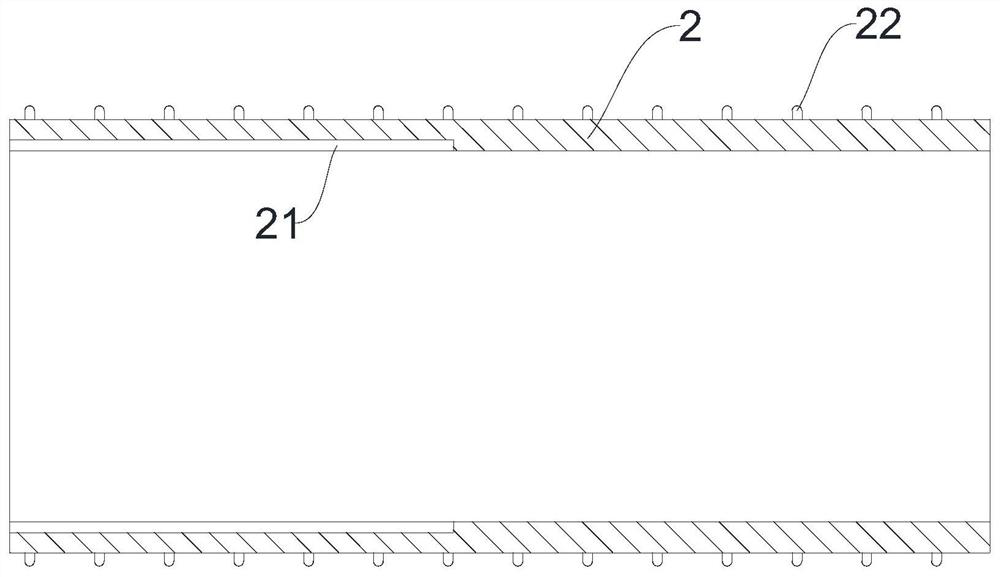

Double-wall corrugated pipe with prefabricated sealing ring and preparation method thereof

A double-wall corrugated pipe and sealing ring technology, which is applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of low ring stiffness, deformation of sockets and sockets, and difficulty in sealing rings, and achieve good sealing performance, Reduced low-temperature resistance and reduced material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Weigh the high-density polyethylene resin, coupling agent, compatibilizer (, reinforcing agent according to the weight part, add to the high-speed mixer and stir for 20 minutes, the temperature reaches 80 ° C, discharge into the cooling mixer, and cool to 38 ° C , and then granulated and bagged for use in the next process.

[0062] (2) Polyvinyl chloride resin, stabilizer, pigment, processing modifier, coupling agent, antioxidant, light stabilizer, compatibilizer, impact modifier are weighed according to parts by weight, and heated in a high-speed mixer , stirred for 30 minutes, and when the temperature reached 135°C, it was discharged into a cooling mixer, and after cooling to 40°C, it was bagged for use in the next process.

[0063] (3) Mix the cooled materials in steps (1) and (2), add them to the mixer and stir for 15 minutes. After the temperature reaches 80°C, discharge them into the cooling mixer, cool to 38°C, granulate and bag.

[0064] (4) Add the mixed m...

Embodiment 2

[0076] The raw materials and content of the pipe are as follows:

[0077] 150 parts of polyvinyl chloride resin; 75 parts of polyethylene resin; 25 parts of active nano-talc powder; 1 part of titanium dioxide; 3 parts of organic tin stabilizer; 10 parts of processing aid DOP; 1 part of polyethylene wax, 1 part of paraffin wax; phosphorous acid 0.5 parts of antioxidant 168, 0.5 parts of light stabilizer benzotriazole, 5 parts of compatibilizer GMA, 10 parts of impact modifier CPE, 5 parts of glass fiber, and 1 part of titanate coupling agent NDZ-401.

Embodiment 3

[0079] The raw materials and content of the pipe are as follows:

[0080] 50 parts of polyvinyl chloride resin; 150 parts of polyethylene resin; 25 parts of active nano wollastonite; 1 part of titanium dioxide; 3 parts of organic tin stabilizer; 10 parts of processing aid DOP; Phosphoric acid antioxidant 168 0.5 parts, light stabilizer benzotriazole 0.5 parts, compatibilizer GMA 5 parts, impact modifier styrene-butadiene rubber 15 parts, solubilizer boron fiber 10 parts, titanate coupling agent NDZ -401 8 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com