Aboriginal efficient denitrification strains of acinetobacter baylyi A9 and citrobacter youngae A13 from rare earth mineral leaching space leachate, and application of aboriginal efficient denitrification strains of acinetobacter baylyi A9 and citrobacter youngae A13 from rare earth mineral leaching space leachate

A technology of ore leaching and field application in the direction of bacteria, chemical instruments and methods, biochemical equipment and methods, etc., can solve problems such as intolerance and insufficient denitrification ability, and achieve good tolerance and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

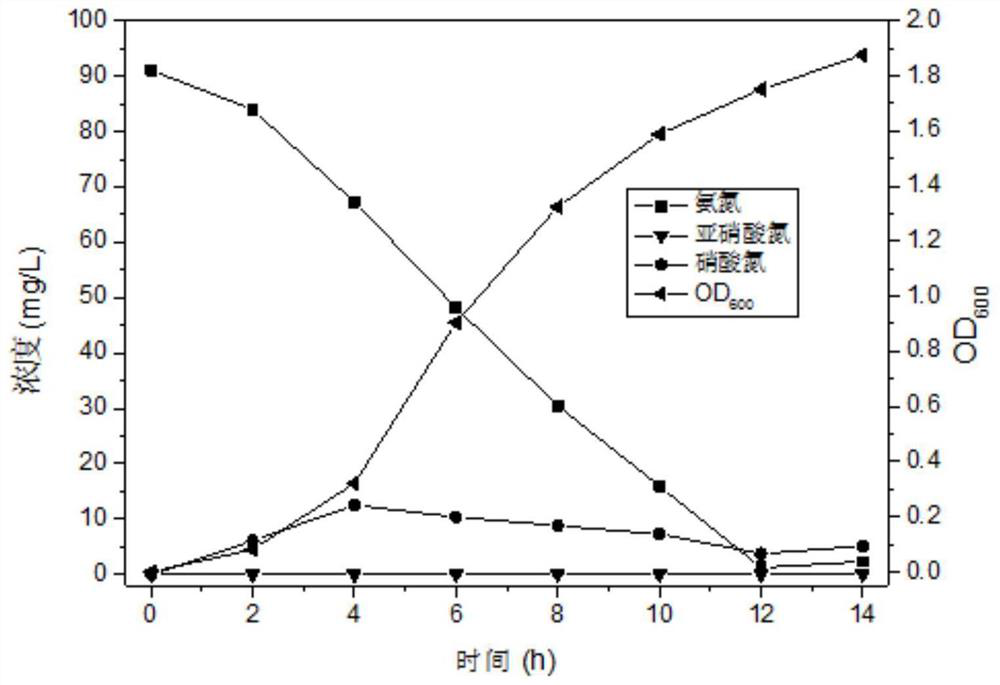

[0039] Inoculate the indigenous high-efficiency denitrification bacterial strain A9 from the rare earth leaching site leachate stored on the inclined surface of the test tube at 4°C into a plate containing a solid medium for denitrification (see 3-(2) for the preparation method of the plate), and inoculate at 28°C Inverted cultivation for 12 hours to realize the activation of the strain. Under sterile conditions, use an inoculation loop to inoculate the activated strain into a 250mL Erlenmeyer flask filled with 100mL of denitrification liquid medium, place the Erlenmeyer flask in a shaker and culture it for 12 hours at 28°C and 165r / min. , to obtain the seed solution. Based on the denitrification liquid medium, the initial concentration of ammonia nitrogen was adjusted to 100 mg / L, and the C / N ratio was 12 to obtain a simulated leachate from a rare earth leaching site. The seed solution was inoculated into 100mL of the sterilized simulated leachate from the rare earth leachin...

Embodiment 2

[0042] Seed liquid was prepared with reference to the method of Example 1. Based on the denitrification liquid medium, the initial concentration of ammonia nitrogen was adjusted to 200 mg / L, and the C / N ratio was 12 to obtain a simulated leachate from a rare earth leaching site. The seed solution was inoculated into 100mL of the sterilized simulated leachate from the rare earth leaching site with 2% inoculum amount, and the shaking culture was carried out under the conditions of 28°C and 165r / min, and samples were taken regularly to measure the ammonia nitrogen content, OD600, Nitrite nitrogen content, nitrate nitrogen content, drawn to get Figure 4 .

[0043] Depend on Figure 4 It can be seen that the concentration of ammonia nitrogen in the simulated leachate of the rare earth leaching site dropped from the initial 200mg / L to 1mg / L after 36 hours of inoculation seed solution treatment, and the removal rate of ammonia nitrogen was as high as 99.5%. At the same time, no ch...

Embodiment 3

[0045] Seed liquid was prepared with reference to the method of Example 1. Based on the denitrification liquid medium, the initial concentration of ammonia nitrogen was adjusted to 300 mg / L, and the C / N ratio was 12 to obtain a simulated leachate from a rare earth leaching site. The seed solution was inoculated into 100mL of the sterilized simulated leachate from the rare earth leaching site with 2% inoculum amount, and the shaking culture was carried out under the conditions of 28°C and 165r / min, and samples were taken regularly to measure the ammonia nitrogen content, OD600, Nitrite nitrogen content, nitrate nitrogen content, drawn to get Figure 5 .

[0046] Depend on Figure 5 It can be seen that the concentration of ammonia nitrogen in the simulated leachate of the rare earth leaching site dropped from the initial 300 mg / L to 5.79 mg / L after 48 hours of inoculation seed solution treatment, and the calculation shows that the removal rate of ammonia nitrogen is as high as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com