All-glass optical atom cavity with vacuum degree higher than 1*10<-8> Pa and preparation method

An all-glass and atomic cavity technology, which is applied in optics, optical components, and material analysis through optical means, can solve problems such as failure to meet ultra-high vacuum environment and chamber cleanliness requirements, film system damage, and increased detection noise. , to achieve the effect of reducing the internal vacuum volume, compact window layout, and ensuring light transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

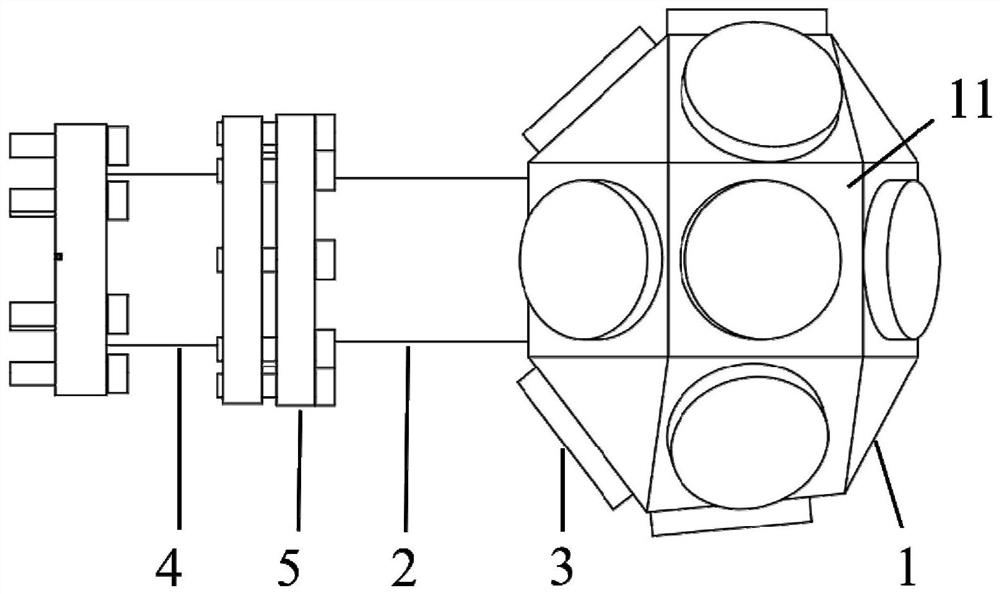

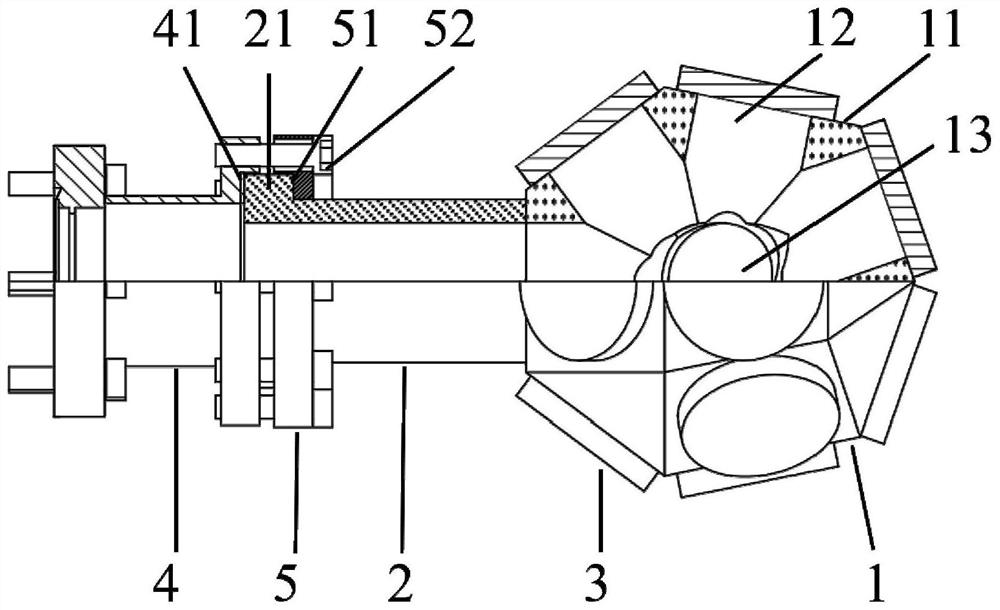

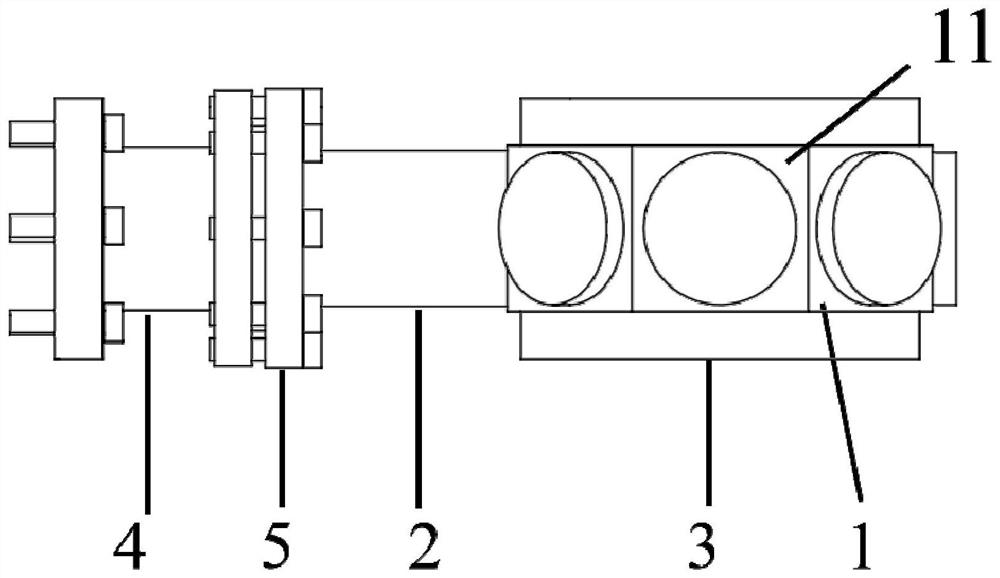

[0064] refer to Figure 3-4 , the all-glass optical atomic cavity of this embodiment:

[0065] The main glass vacuum cavity is a straight octagonal prism, the upper and lower sides are regular octagons, and the side length of the regular octagon is 48mm. The side edge height of the straight octagonal prism is 48mm. On the eight sides of the right prism, a through hole with a diameter of 34mm is opened in the center; on the upper and lower sides, a through hole with a diameter of 95mm is opened in the center. These through-holes form the windows as well as the interior cavity extents. The inner surface of the cavity is polished, and the polishing index: Ra≤1.2nm.

[0066] The upper and lower two large windows have a diameter of 107mm and a thickness of 13mm. The light-passing part is a plane, coated with a 780nm anti-reflection coating, and the transmittance is better than 99%. There are 7 small windows around it, with a diameter of 41mm and a thickness of 7mm. The light-pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com