Photovoltaic installation system

An installation system and photovoltaic technology, applied in the field of photovoltaics, can solve the problems of DC cable consumption and high photovoltaic array line loss, etc., achieve the effect of reducing packaging weight, reducing the amount of electrical connection cables, and solving the effect of long threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

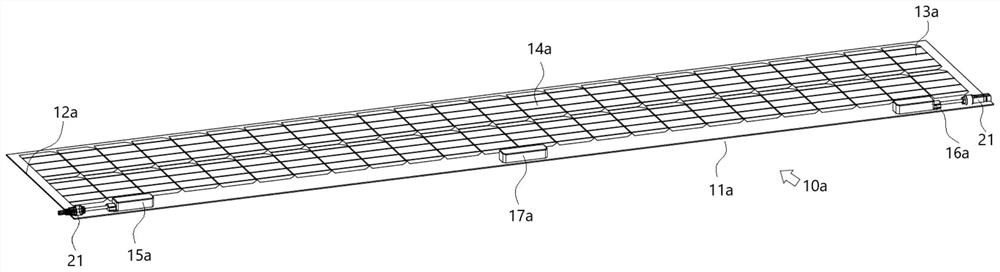

[0065] Example 1: see figure 1 and see in conjunction with Figure 13 As shown, a low line loss photovoltaic array structure includes several photovoltaic modules 10a as photovoltaic array units. Preferably, in this embodiment, the photovoltaic module 10a includes a long side 11a and a wide side 12a; the long side 11a is distributed with 2 photovoltaic cell strings 13a distributed side by side and connected in parallel, wherein each photovoltaic cell string 13a includes 12 (6n, wherein n=2) battery slices 14a connected in series; preferably, in this embodiment, the battery slices 14a adopt 1 / 2 sliced crystalline silicon wafer, this embodiment is referred to as 2 series 1 / 2 sliced photovoltaic module 10a; the single side length of the battery slice 14a is 100-260mm, more preferably, it can be 120-220mm, for example , the unilateral length specification of the entire battery sheet 14a can be 156mm, 158mm, 166mm or 210mm, and the specific specification can be selected accord...

Embodiment 2

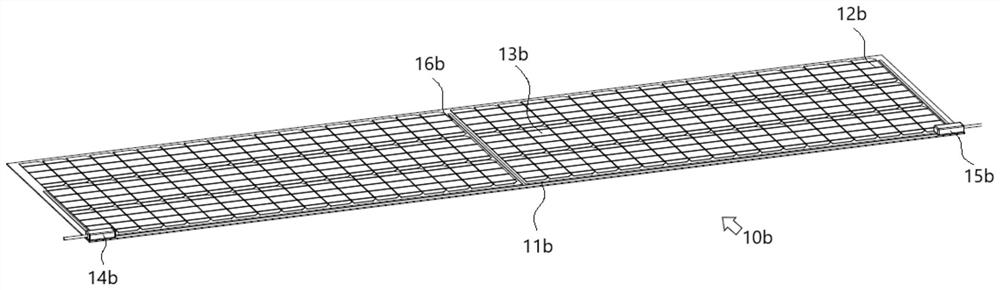

[0071] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that in this embodiment 2, please refer to figure 2In the photovoltaic module 10b shown, three photovoltaic cell strings 12b arranged side by side and connected in series are distributed on the long side 11b, wherein each photovoltaic cell string 12b includes 36 (6n, where n=6) battery sheets 13b connected in series; Preferably, in this embodiment, the cell sheet 13b is a 1 / 3 sliced crystalline silicon sheet, which is referred to as 3 series 1 / 3 sliced photovoltaic modules 10b in this embodiment; The light-receiving surface is respectively provided with a first end-side junction box 14b and a second end-side junction box 15b, the first end-side junction box 14b and the second end-side junction box 15b are located on the same side of the long side 11b, each junction box 14b, 15b They are electrically connected by a bus bar 16b, and no interme...

Embodiment 3

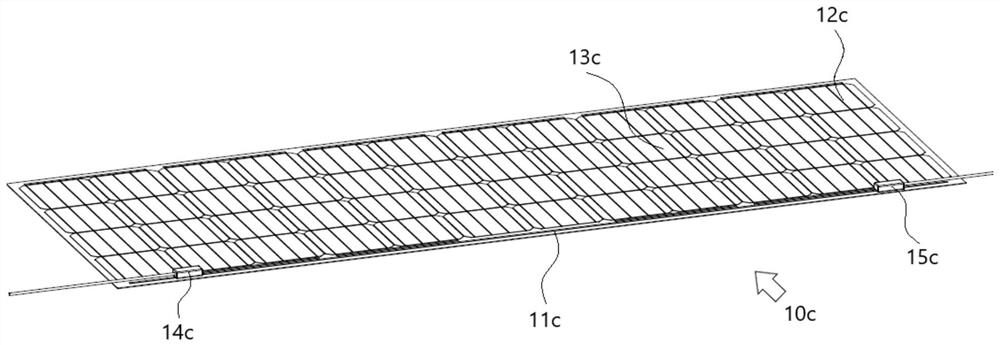

[0072] Embodiment 3: The remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the difference is that in this embodiment 3, please refer to image 3 In the photovoltaic module 10c shown, there are 12 (6n, where n=2) photovoltaic cell strings 12c arranged in parallel and connected in series on the long side 11c, wherein each photovoltaic cell string 12c includes four series-connected cell sheets 13c; Preferably, in this embodiment, the cell 13c is a monolithic crystalline silicon wafer, which is referred to as the 4-series monolithic photovoltaic module 10c in this embodiment; The first end junction box 14c and the second end junction box 15c, the first end junction box 14c and the second end junction box 15c are located on the same side of the long side 11c, the junction boxes 14c, 15c are connected by a bus bar (not shown in the figure) electrical connection, the present embodiment 3 is not provided with an intermediate junction box; a diod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com