A method for flotation separation of lead-zinc sulfide ore containing intergrowth

A lead-zinc sulfide, conjoined technology, applied in solid separation, flotation and other directions, can solve the problems of inability to achieve comprehensive recovery of valuable metals, inability to develop and utilize lead-zinc sulfide ore, loss and other problems, and achieve economical and efficient flotation separation. problems, improve the comprehensive utilization rate, and reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the mass percentage composition of lead in the lead-zinc sulfide ore containing joints of the present embodiment is 3.5%, and the mass percentage composition of zinc is 4.2%;

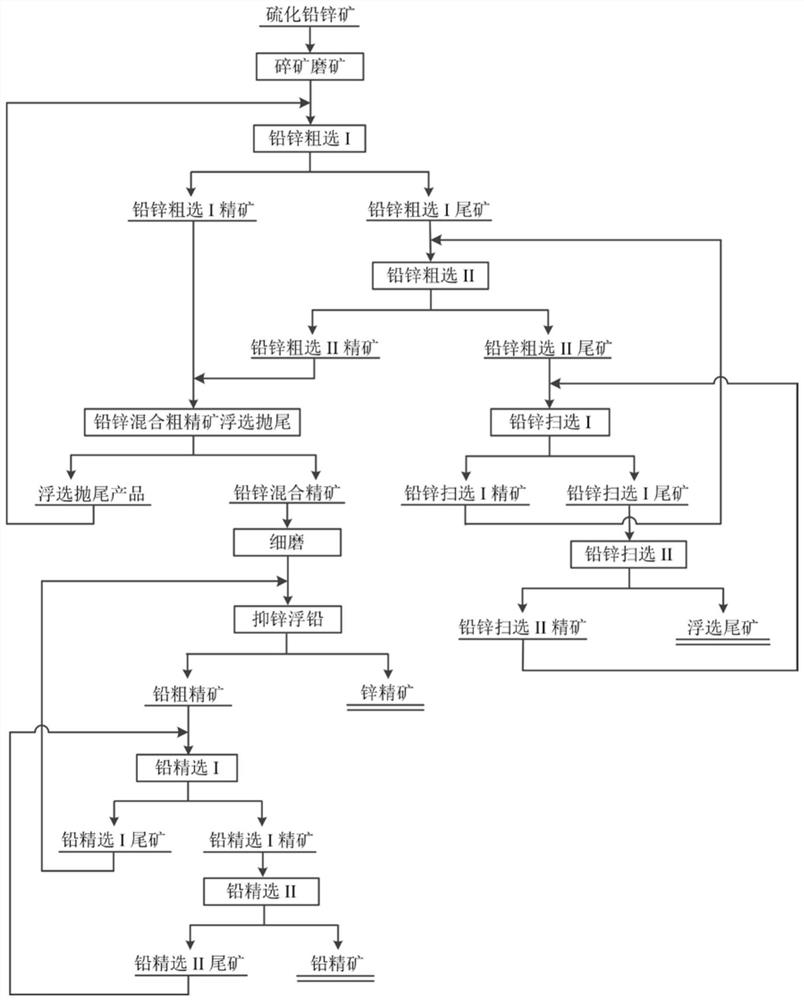

[0036] Such as figure 1 Shown, a kind of method that contains the lead-zinc sulfide flotation separation of intergrowth, concrete steps are as follows:

[0037] (1) Crush and grind the lead-zinc sulfide ore containing conjoined organisms until the mass percent content of -74 μm grain size accounts for 75%, and adjust the pulp until the mass percent concentration of the pulp is 30%, and the sulfide containing concomitant organisms per ton For lead-zinc ore, add 800g lime, 1000g combined inhibitor A, 200g copper ammonium complex, 400g combined collector A and 40g terpineol oil successively in the ore pulp, carry out lead-zinc roughing I operation, obtain lead-zinc crude Concentrate I and lead-zinc roughing I tailings; add 400g lime, 500g combined inhibitor A, 100g copper ammonium com...

Embodiment 2

[0043] Embodiment 2: the mass percentage content of lead in the lead-zinc sulfide ore containing joints of the present embodiment is 5.2%, and the mass percentage content of zinc is 6.7%;

[0044] Such as figure 1 Shown, a kind of method that contains the lead-zinc sulfide flotation separation of intergrowth, concrete steps are as follows:

[0045] (1) Crush and grind the lead-zinc sulfide ore containing conjoined organisms until the mass percentage of -74 μm grain size accounts for 70%, and adjust the pulp until the mass percentage concentration of the pulp is 35%, and the sulfide containing concomitant organisms per ton For lead-zinc ore, add 1200g lime, 1500g combination inhibitor A, 300g cuproammonia complex, 600g combination collector A and 50g terpineol oil successively in ore slurry, carry out lead-zinc roughing I operation, obtain lead-zinc crude Concentrate I and lead-zinc rougher I tailings; Add 600g lime, 750g combined inhibitor A, 150g copper ammonium complex, 300...

Embodiment 3

[0051] Embodiment 3: the mass percentage content of lead in the lead-zinc sulfide ore containing joints of the present embodiment is 6.9%, and the mass percentage content of zinc is 8.3%;

[0052] Such as figure 1 Shown, a kind of method that contains the lead-zinc sulfide flotation separation of intergrowth, concrete steps are as follows:

[0053] (1) Crush and grind the lead-zinc sulfide ore containing conjoined organisms until the mass percent content of -74 μm particle size accounts for 65%, and adjust the pulp until the mass percentage concentration of the pulp is 40%, and the sulfide containing concomitant organisms per ton For lead-zinc ore, add 1600g lime, 2000g combination inhibitor A, 400g copper ammonium complex, 800g combination collector A and 60g pine alcohol oil successively in ore slurry, carry out lead-zinc roughing I operation, obtain lead-zinc crude Concentrate I and lead-zinc roughing I tailings; Add 800g lime, 1000g combined inhibitor A, 200g cuproammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com