Anaerobic digestion wastewater treatment equipment

A technology for wastewater treatment and anaerobic digestion, which is used in anaerobic digestion treatment, water treatment parameter control, biological water/sewage treatment, etc. It can solve the problems of lack of intelligence, occupying space, slow response, etc., and achieve convenient and fast operation. , the structure is simple, the effect of accelerated reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

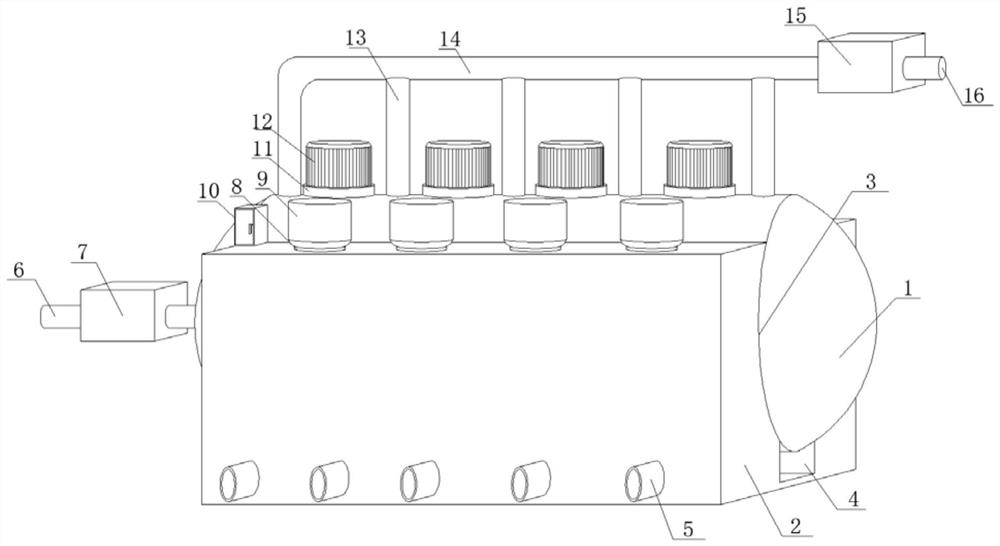

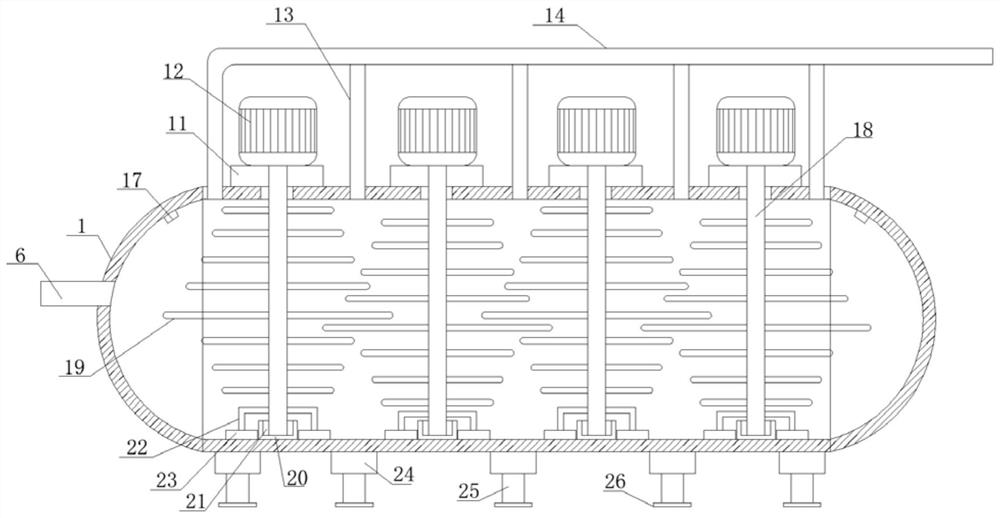

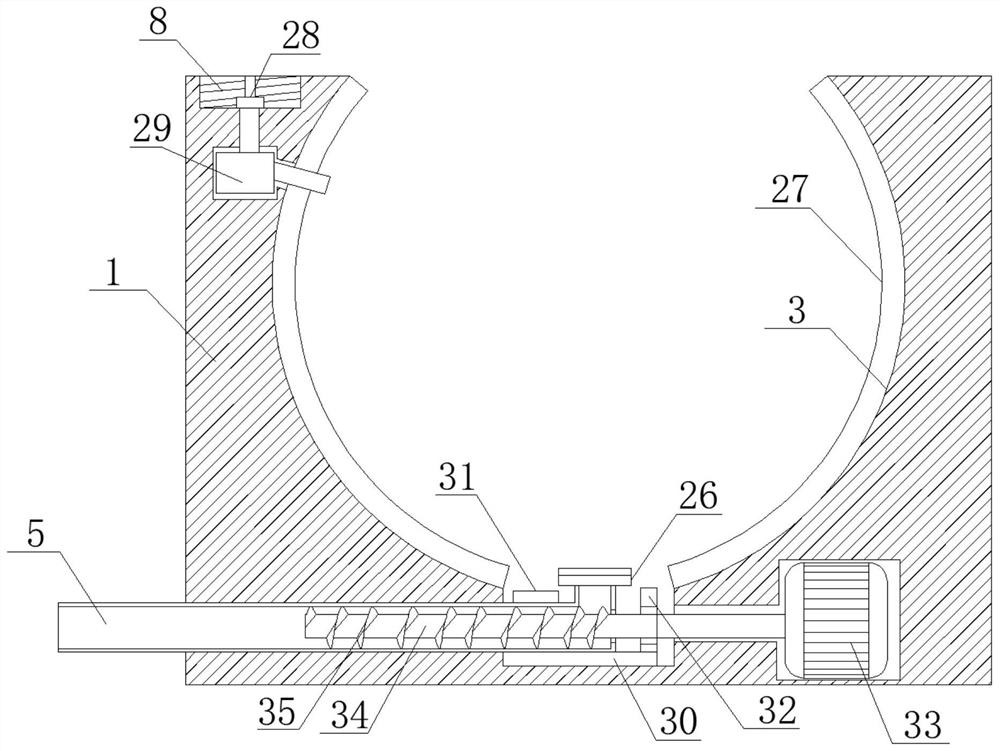

[0027] see Figure 1-2 , 7. In the embodiment of the present invention, an anaerobic digestion wastewater treatment equipment includes a main treatment tank 1, the outer side of the main treatment tank 1 is docked with a supporting outer plate 2, and the inner side of the supporting outer plate 2 is horizontally provided with The clamping groove 3, the main processing tank 1 is arranged horizontally and horizontally, the supporting outer plate 2 is made of concrete material, and the main processing tank 1 is horizontally clamped on the inner side of the clamping groove 3 at the center of the supporting outer plate 2, and the clamping The slot 3 is horizontally opened on the support outer plate 2 and runs through both ends of the support outer plate 2 to the outer side, and the locking slot 3 runs through the top surface of the support outer plate 2 and extends to the outer side. The bottom surface is vertically and horizontally opened with an extension groove 4, and the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com