Oilfield polymer viscosity loss inhibitor and use method thereof

A viscosity loss and polymer technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unstable polymer viscosity and large loss, and achieve easy acquisition, improved stability, and reduced production input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

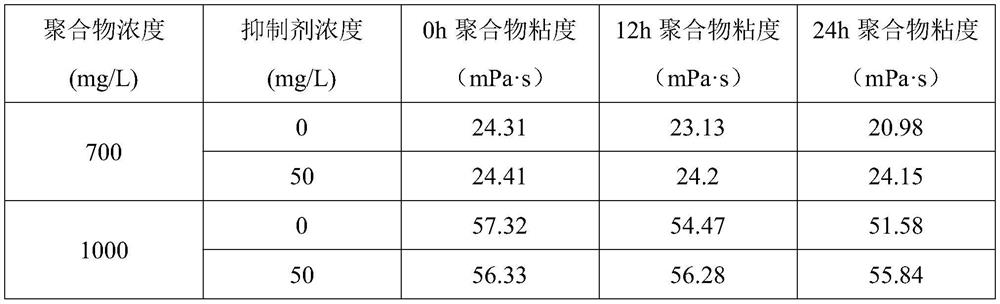

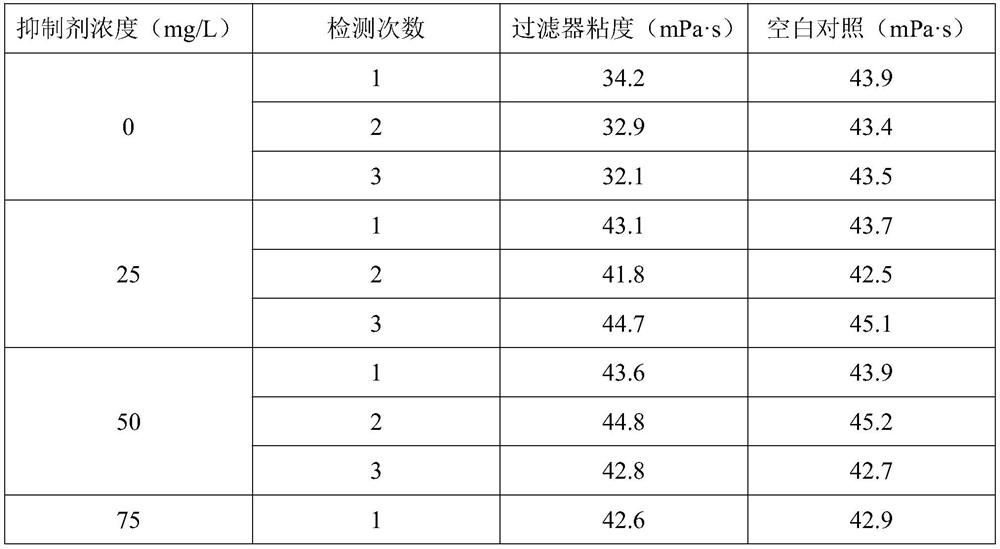

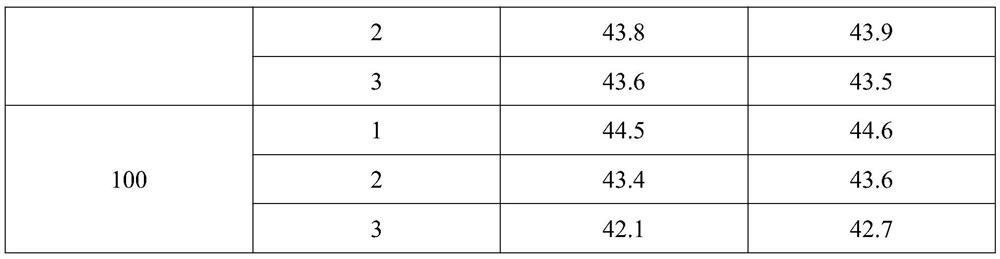

Examples

specific Embodiment approach 1

[0015] Embodiment 1: In this embodiment, an oilfield polymer viscosity loss inhibitor is composed of 5-20% nitrite, 0.1% sodium hydroxide, 0.01-0.03% nutrient elements, 0.1-0.5% % of synergistic inhibitors and the balance made of water.

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nutrient element is a mixture of sodium nitrate, potassium nitrate and sodium nitrite; wherein, the volume ratio of sodium nitrate, potassium nitrate and sodium nitrite is 0.5 :0.5:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: described synergistic inhibitor is the mixture of ammonium molybdate and sodium molybdate; Wherein, the volume ratio of ammonium molybdate and sodium molybdate is 1: 1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com