Anode copper ball anti-drop cylinder efficiency improvement device

An anode copper ball, anti-drop technology, applied in the direction of the electrode, etc., can solve the problems of large loss of electroplating solution, phosphorus copper ball falling into the plating tank, and high degree of manual dependence, so as to increase storage capacity, reduce loss, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

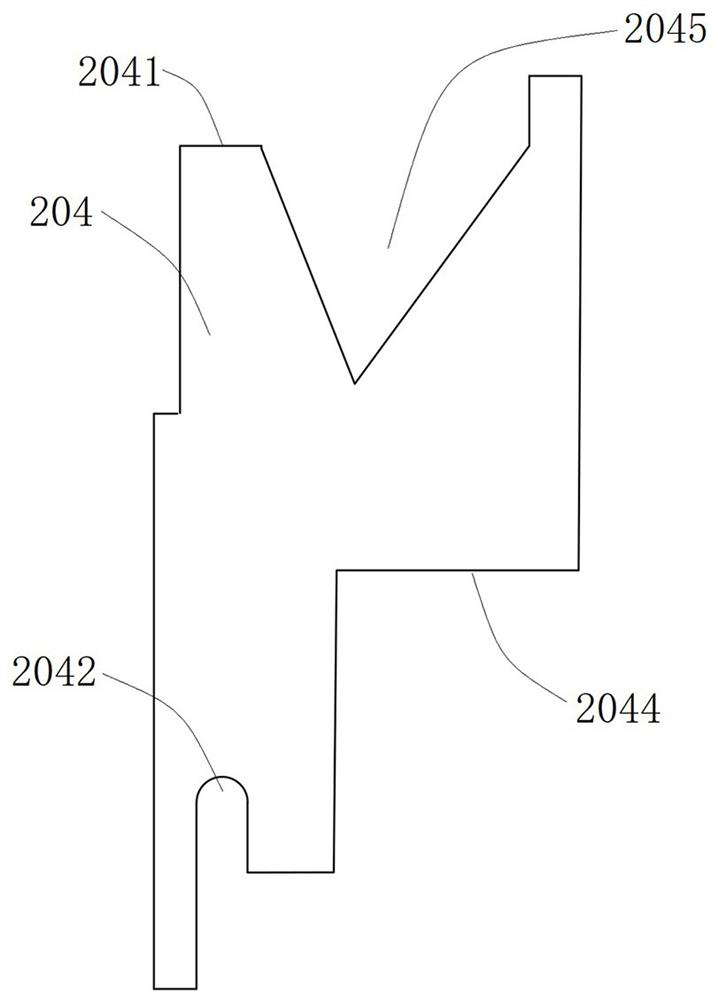

[0029] Such as Figure 1-9 , the anode copper ball anti-falling cylinder efficiency improvement device, including the plating cylinder 100 equipped with electroplating solution, the feeding device 200, the feeding device 200 includes a material receiving assembly 201, a material receiving variable diameter assembly 202, a titanium basket 203, a material receiving bracket 204 . At least one support assembly is horizontally arranged in the middle of the coating cylinder 100, and the support assembly carries the material receiving assembly 201 on the top of the plating cylinder 100 through the material receiving bracket 204, and several installation positions 2012 provided in the middle of the material receiving assembly 201 are connected to the titanium plate by the material receiving variable diameter assembly 202. The baskets 203 are connected, and the titanium baskets 203 are arranged laterally along the support assembly in the middle of the plating tank 100 to be suspended i...

Embodiment 1

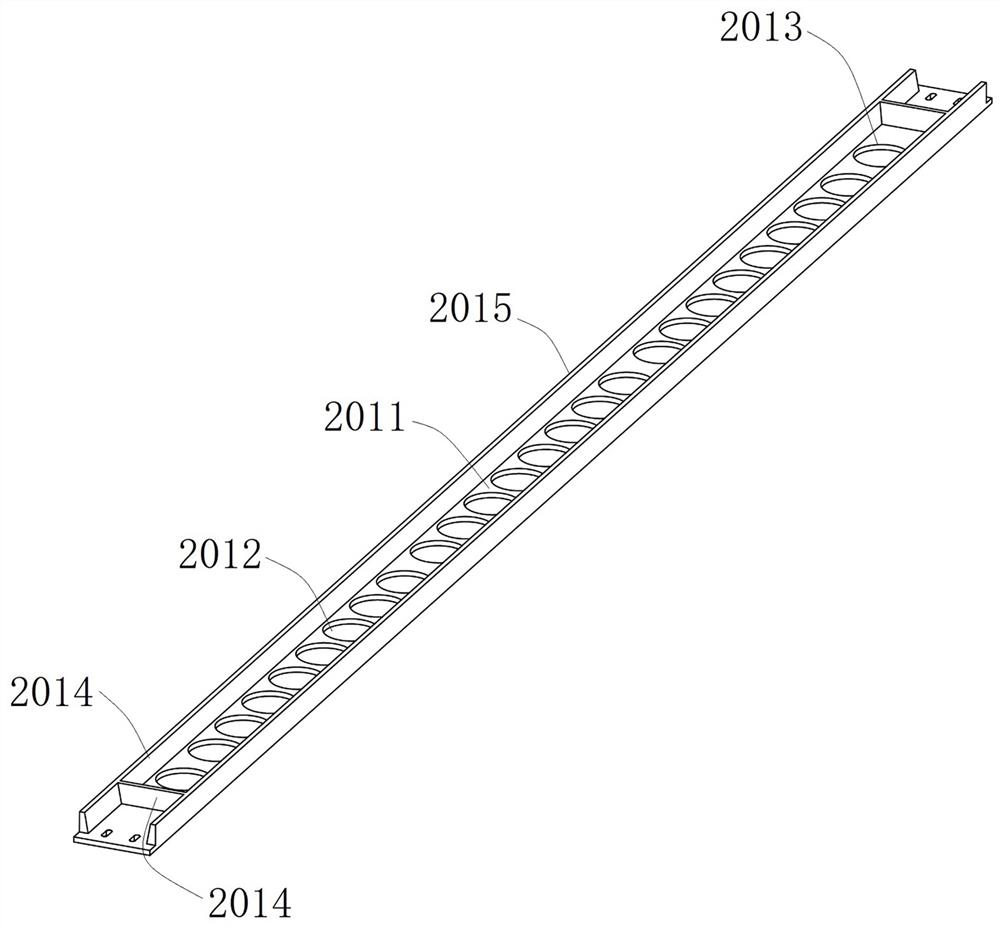

[0047] Such as figure 2 , 4, the peripheral edge of the material receiving assembly 201 extends toward the top to form an anti-drop plate 2014 suitable for phosphor bronze balls, so that the guide groove 2011 in the middle of the material receiving assembly 201 is formed between the anti-drop plates 2014, and several installation positions are set in the middle of the guide groove 2011 2012, the mounting positions 2012 are arranged laterally in the middle of the guide groove 2011 to form a mounting row 2013, and the material receiving component 201 adopts the first material receiving component 2015 with a mounting row 2013 in the middle. The support assembly includes a first support assembly 101 horizontally arranged in the middle of the plating tank 100. The first support assembly 101 has suspension assemblies 1011 at both ends. Corresponding to the first supporting component 101 , a connecting piece 2032 is disposed on the side of the titanium basket 203 close to the first...

Embodiment 2

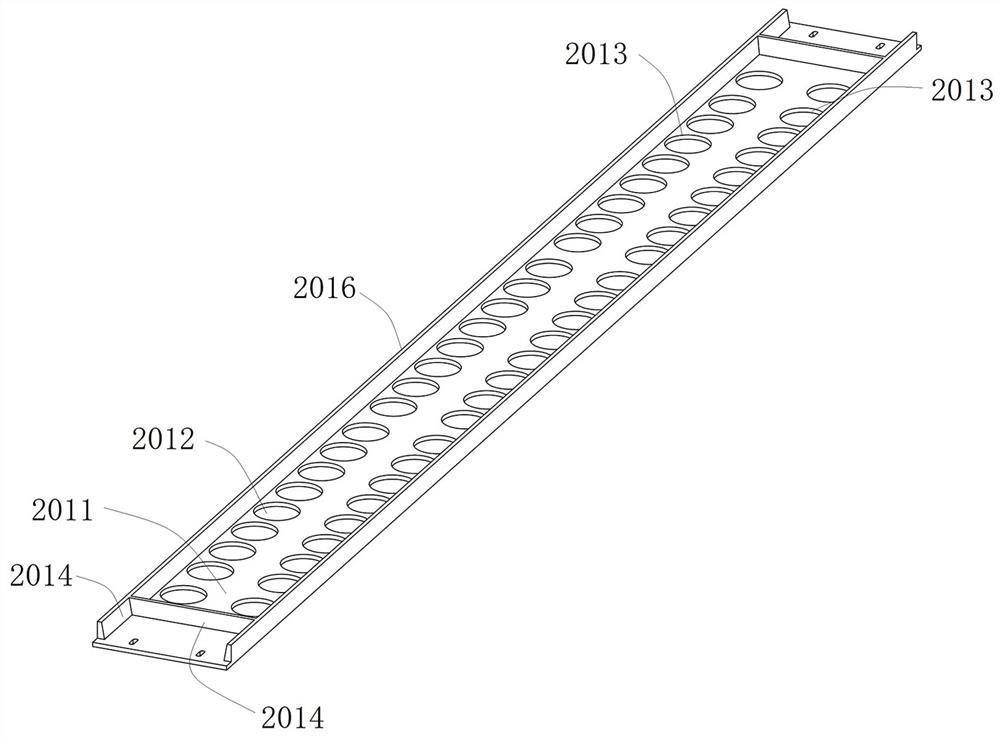

[0052] Such as image 3 , 5 , the peripheral edge of the material receiving assembly 201 extends toward the top to form an anti-drop plate 2014 suitable for phosphor bronze balls, so that the guide groove 2011 in the middle of the material receiving assembly 201 is formed between the anti-drop plates 2014, and several installation positions are set in the middle of the guide groove 2011 2012, the mounting positions 2012 are arranged laterally in the middle of the guide groove 2011 to form a mounting row 2013, and the material receiving component 201 adopts a second material receiving component 2016 with at least two mounting rows 2013 in the middle. The support assembly includes a second support assembly 102 horizontally arranged in the middle of the plating tank 100, and a titanium basket is installed corresponding to the second support assembly, so that after the installation of the second material receiving assembly is completed, the second support assembly 102 runs through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com