Mask made of nano-filtration material

A technology of nano-filtration and nano-filtration layer, applied in applications, clothing, clothing, etc., can solve the problems of reduced filtration efficiency, cumbersome steps, large pores, etc., and achieve the effects of improving user comfort, simple preparation method, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The inner surface of the mask is made of non-woven fabric layer, and the non-woven fabric layer and the nano-filtration layer in contact with it are bonded in a dot matrix. The nano-filtration layer includes two layers of hierarchical unit membranes. The hierarchical unit membranes are polytetrafluoroethylene membranes. There are several transverse partitions between the membranes to divide the cavity into several transverse cavities. There are a number of micro springs at both ends of the cavity. Nano-titanium dioxide and sterilizing balls are built in the cavity. The sterilizing ball includes a shell, which is multi-shelled. A layer of nano-catalytic material, which has a hollow structure and can accommodate sterilizing substances, and the sterilizing substances are silver oxide with a particle size of 100nm-150nm. The outer layer of the nanometer filter layer is also provided with a protective layer, and the protective layer is a non-woven filter cotton.

Embodiment 2

[0033] The technical solution of this embodiment is roughly the same as that of Embodiment 1, and the similarities will not be described in detail. The difference is:

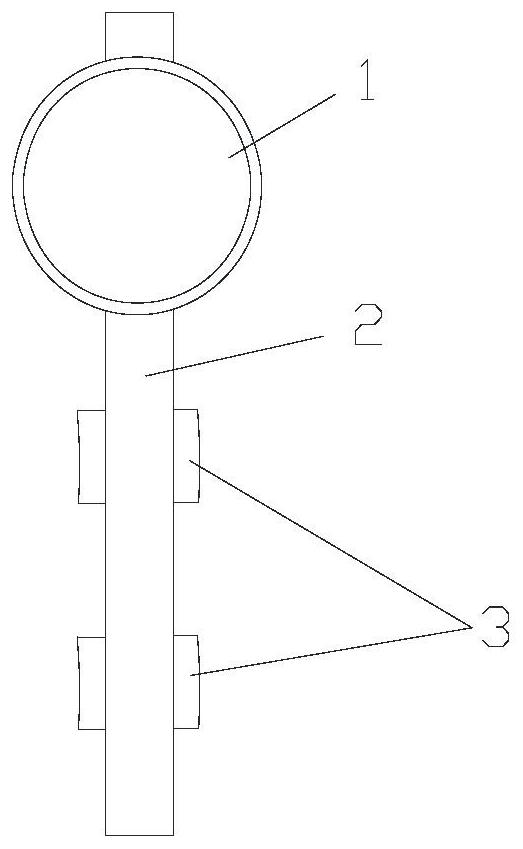

[0034] The protective layer is provided with a breathing valve 1 and a vertical guide rail 2. The breathing valve 1 slides along the vertical guide rail 2. The vertical guide rail 2 is equipped with several card point devices corresponding to the breathing valve 1. The protective layer corresponds to several card point devices. There are several vent holes, the vent holes are provided with detachable rubber plugs, and the contact position between the breathing valve and the vent hole is provided with a connecting flange, the flange and the protective layer are closely fitted, and the sticking point device includes a sticking protrusion arranged on the breathing valve 1, a vertical The guide rail 2 is provided with a plurality of locking positions 3 that are interference fit with the locking protrusions correspon...

Embodiment 3

[0036] The technical solution of this embodiment is roughly the same as that of Embodiment 1, and the similarities will not be described in detail. The difference is:

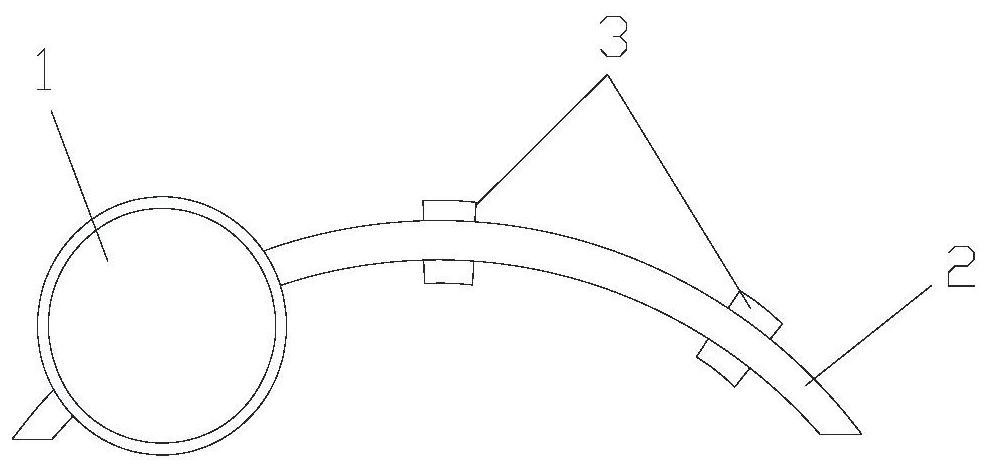

[0037] The protective layer is provided with breathing valve 1 and arc-shaped guide rail 2. The breathing valve 1 slides along the arc-shaped guide rail 2. The arc-shaped guide rail 2 is equipped with several card point devices corresponding to the breathing valve 1. The protective layer is equipped with several card point devices corresponding to several points. There are two vent holes, the vent holes are provided with detachable rubber plugs, and the contact position between the breathing valve and the vent holes is provided with a connecting flange, and the flange and the protective layer are closely fitted. The user can first pull out the detachable rubber plug on the air hole at a certain position, and then move the breathing valve 1 along the arc guide rail, and adjust the most suitable position of the br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Inhalation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com