A kind of tungsten-energy high entropy alloy composite material and its preparation method

A technology of composite materials and entropy alloys, which is applied in the field of tungsten-energy-containing high-entropy alloy composite materials and its preparation, can solve problems such as unbearable detonation loading, deterioration of mechanical properties of tungsten-zirconium alloys, and reduced energy release efficiency, etc., to achieve easy Industrialized production, improved energy release efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

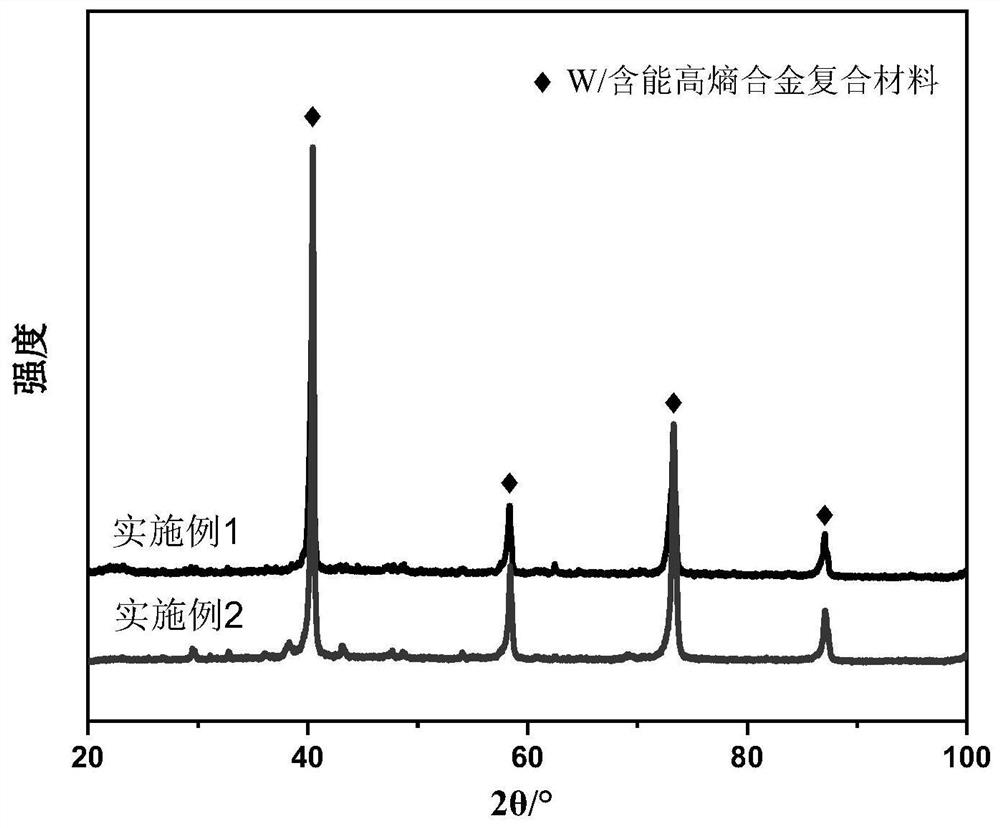

Embodiment 1

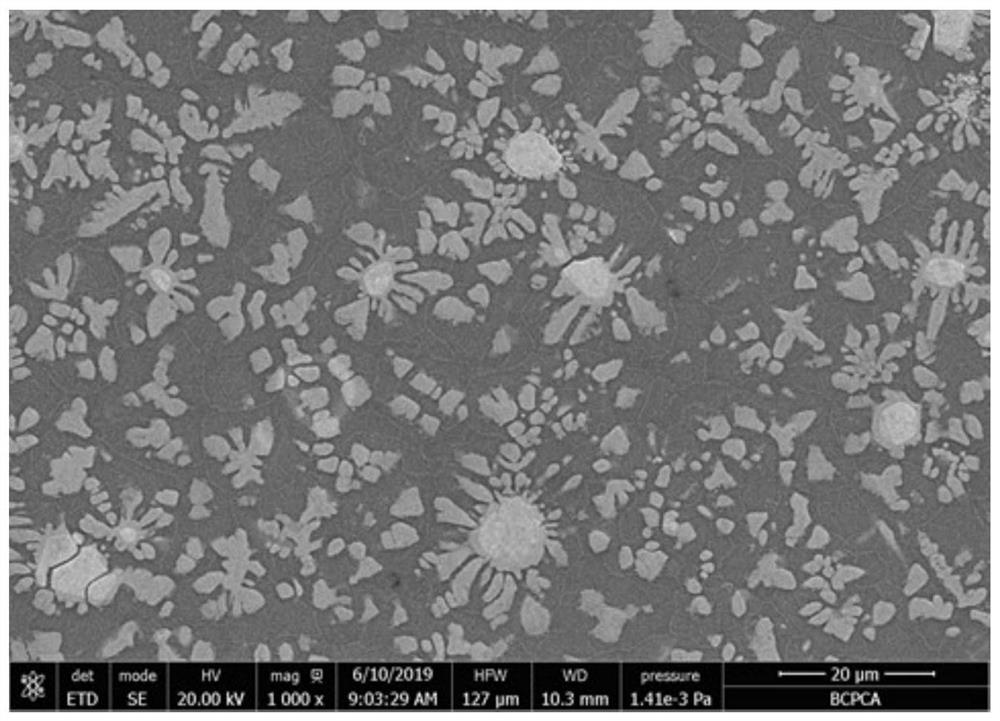

[0038] In Nb 17 Zr 21 Ti 62 Energetic high-entropy alloy as matrix phase and tungsten particles as reinforcement phase to prepare 50wt.%W / Nb 17 Zr 21 Ti 62 The specific steps of composite materials are as follows:

[0039] (1) Grinding with a grinding wheel to remove the oxide scales on the surface of the elemental elements Nb, Zr and Ti, then using absolute ethanol to perform ultrasonic vibration cleaning, and weighing out a clean raw material with a total mass of 2 kg according to the atomic percentage between each element;

[0040] (2) Put the weighed elemental elements into the water-cooled copper crucible of the vacuum air atomization powder making furnace, and then vacuumize until the vacuum degree in the furnace reaches 3×10 -3 Pa, filled with high-purity argon as a protective gas, and then carry out alloy melting, after the alloy is completely melted into alloy liquid, argon is used as the atomization medium, and the alloy is heated at a heating power of 160kW and...

Embodiment 2

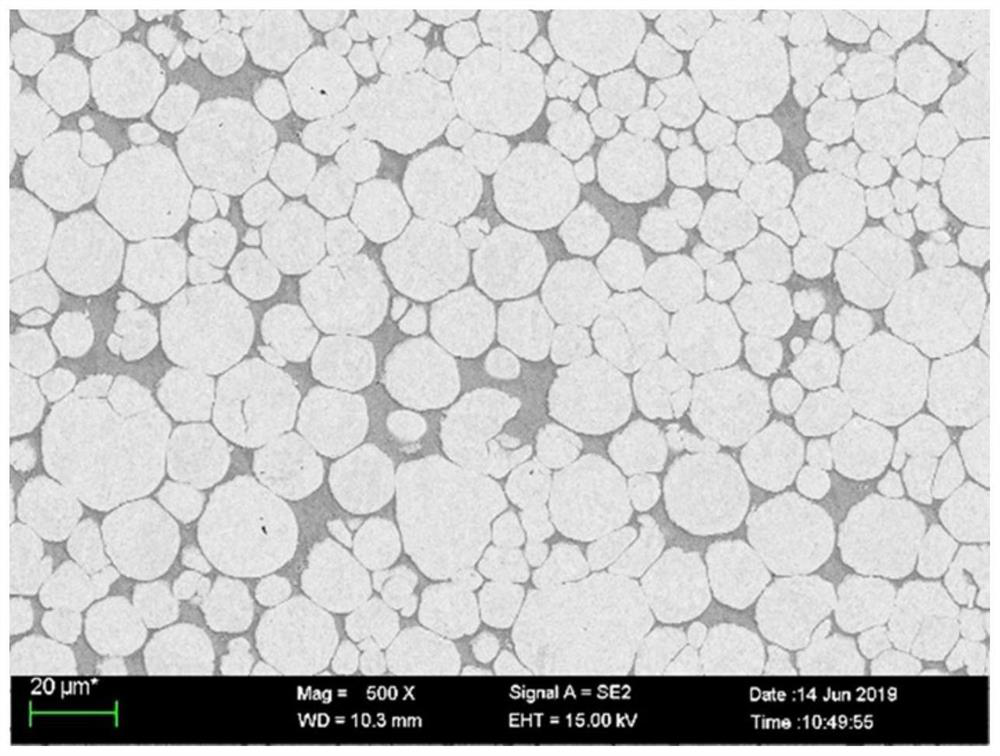

[0045] In Nb 17 Zr 21 Ti 62 Energetic high-entropy alloy as matrix phase and tungsten particles as reinforcement phase to prepare 80wt.%W / Nb 17 Zr 21 Ti 62 The specific steps of composite materials are as follows:

[0046] (1)~(2) are identical with the steps (1)~(2) of embodiment 1;

[0047] (3) Tungsten powder with a particle size of 15 μm to 50 μm and Nb with a particle size of 45 μm to 75 μm in step (2) 17 Zr 21 Ti 62 The powder is added into the ball mill according to the mass ratio of 8:2, the ball-to-material ratio is 9:1, and the powder is mixed at a speed of 250r / min for 12h under the protection of argon to obtain a composite powder;

[0048] (4) Put the composite powder in a cold isostatic pressing mold, hold the pressure at 300MPa for 0.5h, and obtain a blank with a size of φ15mm×100mm; then place the blank in a vacuum tube furnace, under an argon atmosphere, with Heating at a heating rate of 10°C / min to 1670°C, holding the temperature for 0.5h, and cooling...

Embodiment 3

[0051] to Ti 40 V 20 Ta 35 Zr 4 Cr 1 Energetic high-entropy alloy as matrix phase and tungsten particles as reinforcement phase to prepare 93wt.%W / Ti 40 V 20 Ta 35 Zr 4 The specific steps of Cr composite material are as follows:

[0052] (1) First use a grinding wheel to remove the oxide scales on the surface of the elemental elements Ti, V, Ta, Zr and Cr, then use absolute ethanol to perform ultrasonic vibration cleaning, and weigh the total mass according to the atomic percentage of each element to be 2kg clean raw materials;

[0053] (2) Put the weighed elemental elements into the water-cooled copper crucible of the vacuum air atomization powder making furnace, and then vacuumize until the vacuum degree in the furnace reaches 3×10 -3 Pa, filled with high-purity argon as a protective gas, and then carry out alloy melting, after the alloy is completely melted into alloy liquid, argon is used as the atomization medium, the heating power is 180kW, and the atomization p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com