Roadbed treatment method based on vacuum dewatering combined with dynamic compaction

A treatment method, a vacuum technology, applied in roads, roads, soil protection, etc., can solve the problem that the subgrade cannot meet the long-term operation requirements of the road, and achieve good reinforcement effects, improved compactness, and enhanced reinforcement effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

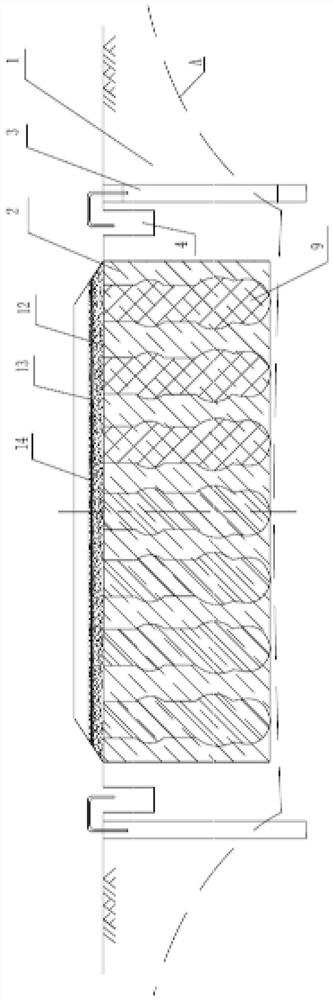

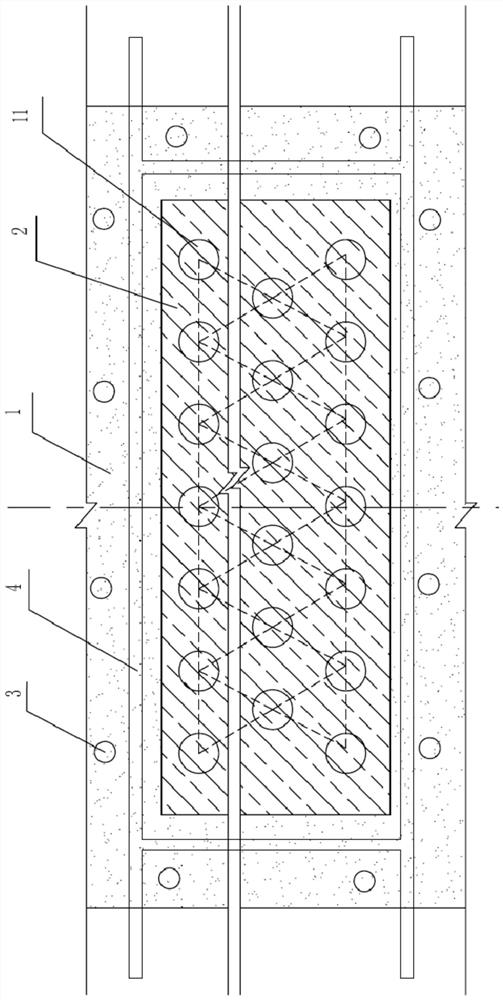

[0039] Such as figure 1 , figure 2 As shown, the present invention discloses a roadbed treatment method based on vacuum precipitation combined with dynamic compaction, comprising the following steps:

[0040] S1. Construction preparation.

[0041] Clean up and level the ground within the road range, set the precipitation drilling area 1 and the dynamic compaction area 2, the precipitation drilling area 1 surrounds the dynamic compaction area 2, and calculate the subgrade treatment depth according to the road operation requirements.

[0042] S2. Borehole buried pipe.

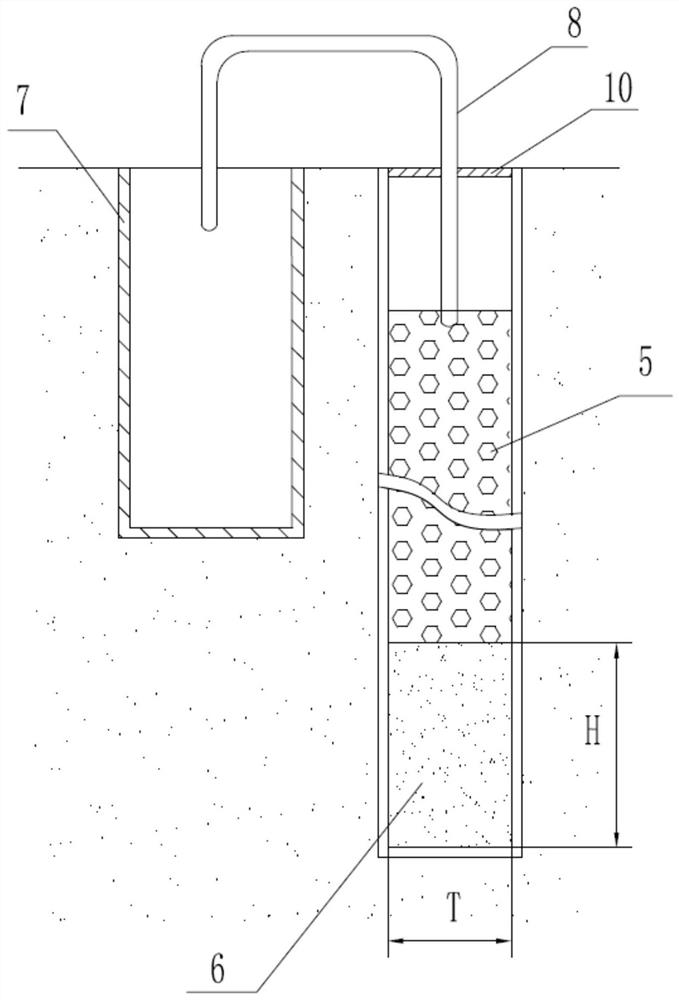

[0043] Such as image 3 As shown, the vacuum dewatering well 3 is set, and the diameter T of the vacuum dewatering well 3 is set to 0.5-0.8m. The well depth is determined according to the depth of the roadbed treatment. 3 to determine the well spacing. On-site stakeout determines the position of the vacuum dewatering well 3, and the mechanical drilling is formed into the well body of the vacuum dewatering w...

Embodiment 2

[0056] The difference between this embodiment and the first embodiment is that the specific steps of step S3 of dynamic compaction filling are different from those of the first embodiment. The process of dynamic compaction filling in the present embodiment is as follows:

[0057] (1) Carry out wire laying and distribution in the dynamic compaction area 2, and pour part of the reinforcing body 9 above each distribution point.

[0058] (2) Use a tamper to ram the reinforcing body 9, so that the reinforcing body 9 sinks and squeezes the soil layer to both sides.

[0059] (3) After the reinforcing body 9 sinks until the site is level, continue to pour the reinforcing body 9 above the distribution point.

[0060] (4) Steps (2) and (3) are repeated for tamping with a rammer until the reinforcing body is tamped to the depth of the subgrade treatment.

[0061] (5) The site is treated with full compaction, and the rammers overlap each other to form a strong compaction reinforcement l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com