Liquid combustion system and combustion method capable of obtaining high-stability flame based on high precision control

A combustion system, high stability technology, applied in the field of energy and environment, can solve the problem of not considering the condensation of the burner, achieve the effect of solving the instability of the combustion flame, avoiding low heating temperature, improving simplicity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

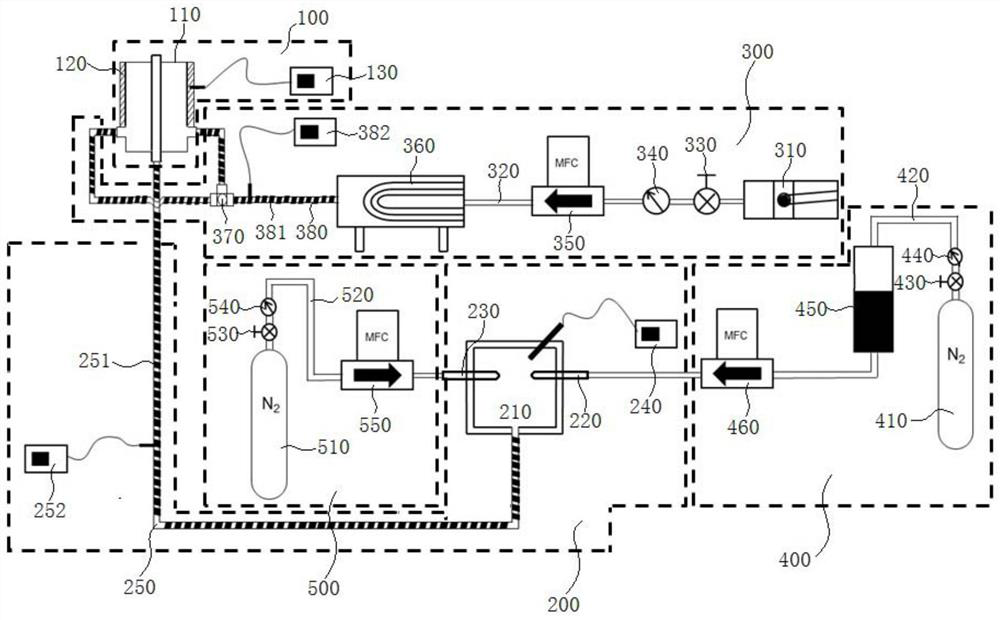

[0047] Such as figure 1 As shown, the liquid combustion system based on high-precision control to obtain a highly stable flame includes a combustion unit 100 , an evaporative atomization unit 200 , an air supply unit 300 , a fuel unit 400 and a carrier air unit 500 .

[0048] Wherein, the combustion unit 100 includes a burner 110, the outer surface of the burner 110 is wrapped with a heating ring 120, and the heating ring 120 is connected with a third thermocouple and a temperature controller 130, and the burner 110 includes a fuel side and a Oxidant side (not marked in the figure). A heating ring is installed on the outer wall of the burner and connected to the third thermocouple and a thermostat to precisely control the air outlet temperature, which can not only obtain a highly stable flame, but also ensure the accuracy of the obtained data.

[0049] Further, the evaporative atomization unit 200 includes an evaporative atomization chamber 210, and the evaporative atomizatio...

Embodiment 2

[0057] The liquid combustion method of high-precision control and high-stable flame in this embodiment adopts the system in Embodiment 1, and the specific steps are as follows:

[0058] Step 1. Heating the compressed air to 150°C in the air heater 360 and passing it into the oxidant inlets on both sides of the burner 110, as a protective gas and a combustion-supporting gas for the combustion of the hot body fuel after evaporation and atomization;

[0059] Step 2, the mixed fuel of n-heptane and ethanol from the liquid injection needle 220 and the N from the gas injection needle 230 2 Fully mixed in the evaporation atomization heating chamber and heated to 150 ° C, when the heating temperature exceeds the boiling point of the mixed fuel of n-heptane and ethanol, the liquid droplets will be evaporated into a gaseous state;

[0060] Step 3. In order to avoid condensation of the mixed fuel vapor of n-heptane and ethanol in the process leading to the burner 110, the first stainless...

Embodiment 3

[0063] The liquid combustion method of high-precision control and high-stable flame in this embodiment adopts the system in Embodiment 1, and the specific steps are as follows:

[0064] Step 1. Heating the compressed air to 250°C in the air heater 360 and passing it into the oxidant inlets on both sides of the burner 110, as a protective gas and a combustion-supporting gas for the liquid fuel combustion after evaporation and atomization;

[0065] Step 2, the mixed fuel of gasoline and ethanol from the liquid injection needle 220 and the N from the gas injection needle 230 2 Fully mixed in the evaporation atomization heating chamber and heated to 250°C, when the heating temperature exceeds the boiling point of the mixed fuel of gasoline and ethanol, the liquid droplets will be evaporated into a gaseous state;

[0066] Step 3. In order to avoid condensation of the mixed fuel vapor of gasoline and ethanol on the way to the burner 110, the first stainless steel pipeline 250 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com