Organic-inorganic composite solid electrolyte film, preparation method thereof and solid-state lithium metal battery

A solid electrolyte and inorganic composite technology, which is applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, lithium batteries, etc., can solve the problem of low conductivity of the electrolyte membrane, and achieve the effect of simple preparation method, high ion conductivity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The ionic liquid is N-methyl-N-methoxyethylpyrrolidine bistrifluoromethanesulfonimide salt (Pyr 1(201) TFSI) as an example:

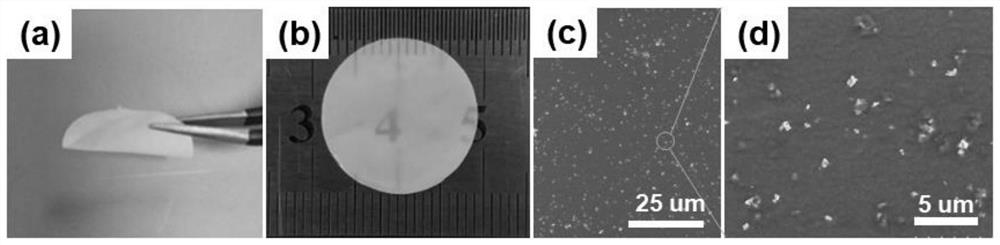

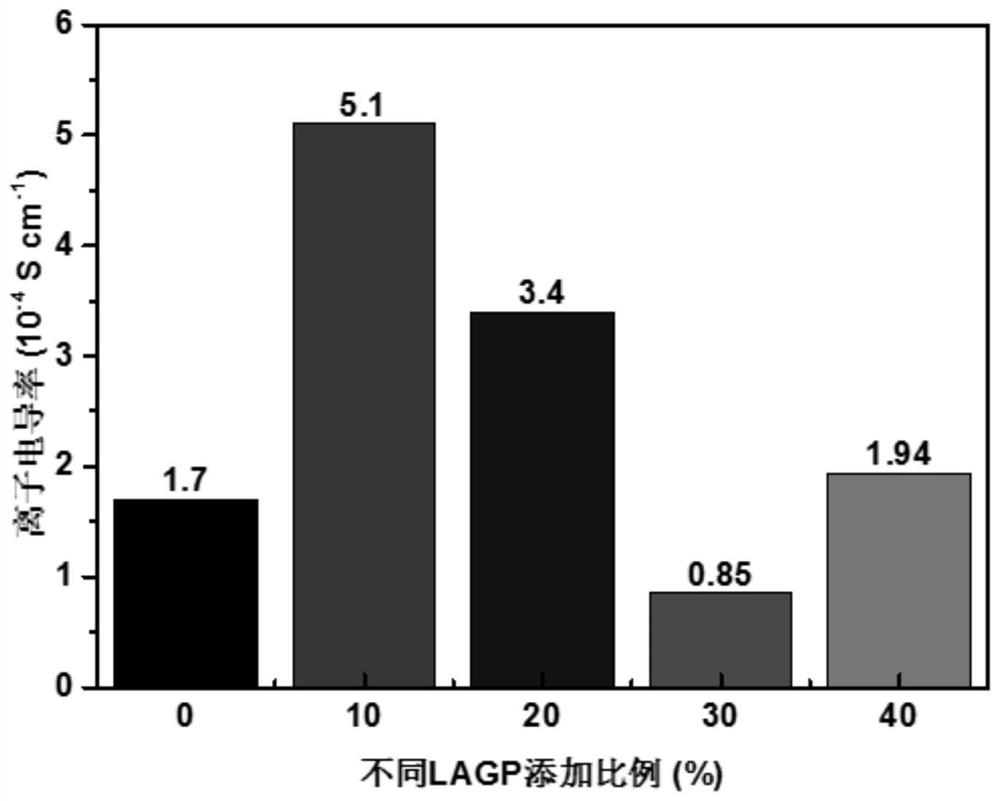

[0035] The organic-inorganic composite solid electrolyte was prepared by solution casting method. Dispersion of LiTFSI in Pyr by ultrasound 1(201) TFSI to obtain 1mmol g -1 Ionic liquid (denoted as IL). Weigh 1 g of polyvinylidene fluoride powder (PVDF) after vacuum drying (60° C., 24 h), put it in 8 g of NMP and stir for 48 h. The LAGP ceramic powder was ground at 60 °C for 30 min under vacuum. Then, the LAGP and IL obtained by the above pretreatment were added to the PVDF solution, the mass ratio was PVDF:IL:LAGP=100:100:22.5, and the stirring was continued for 12 hours at a speed of 600r / min. The uniform slurry was cast onto a glass plate, and the film was scraped off at a constant speed using a spreader (150 μm). Finally, the film was vacuum-dried at 60°C for 8 hours to remove NMP to obtain an organic-inorganic composite solid electroly...

Embodiment 2

[0044] The ionic liquid in this embodiment is 1-ethyl-3-methylimidazolium bistrifluoromethanesulfonimide salt (EMITFSI).

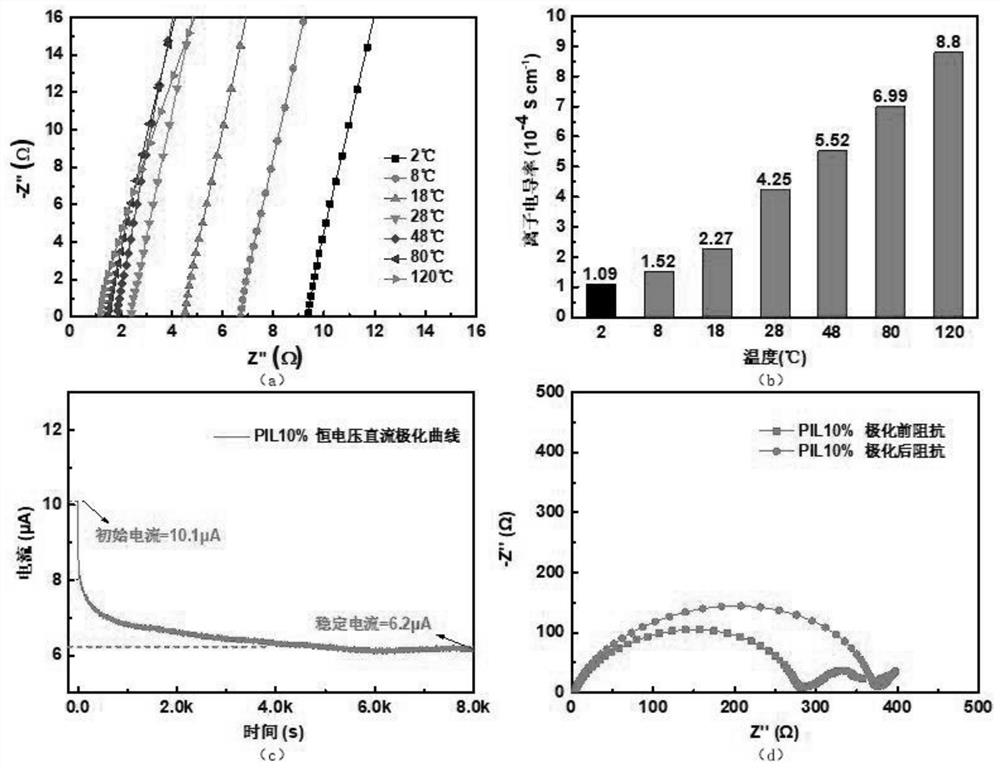

[0045] The organic-inorganic composite solid electrolyte was prepared by solution casting method. Disperse LiTFSI in EMITFSI by ultrasound to obtain 1 mmol g -1 Ionic liquid (denoted as IL). The LAGP ceramic powder was ground at 60 °C for 30 min under vacuum. Get 0.1g PVDF powder, then weigh IL 0.1g, LAGP powder 22.5mg, add 0.7g NMP (N-methylpyrrolidone) to the above mixture, stir continuously for 12h, and the rotating speed is 600r / min. The uniform slurry was cast onto a glass plate, and the film was scraped off at a constant speed using a spreader (150 μm). Finally, the film was vacuum-dried at 60°C for 8 hours to remove NMP to obtain an organic-inorganic composite solid electrolyte (denoted as PIL10%). It should be noted that since LiTFSI is sensitive to moisture, IL must be configured in an argon-filled glove box.

[0046] A lithium battery was pr...

Embodiment 3

[0048] The ionic liquid of the present embodiment is N-methyl-N-butylpyrrolidine bistrifluoromethanesulfonic acid imide (Pyr 14 TFSI).

[0049] The organic-inorganic composite solid electrolyte was prepared by solution casting method. Dispersion of LiTFSI in Pyr by ultrasound 14 TFSI to obtain 1mmol g -1 Ionic liquid (denoted as IL). The LAGP ceramic powder was ground at 60 °C for 30 min under vacuum. Get 0.1g PVDF powder, then weigh IL 0.1g, LAGP powder 22.5mg, add 0.7g NMP (N-methylpyrrolidone) to the above mixture, stir continuously for 12h, and the rotating speed is 600r / min. The uniform slurry was cast onto a glass plate, and the film was scraped off at a constant speed using a spreader (150 μm). Finally, the film was vacuum-dried at 60°C for 8 hours to remove NMP to obtain an organic-inorganic composite solid electrolyte (denoted as PIL10%). It should be noted that since LiTFSI is sensitive to moisture, IL must be configured in an argon-filled glove box.

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com