Repair/modification method for metallic substrates

A base material and metal technology, which is applied in the repair and modification of metal base materials, can solve problems such as poor product quality, influence, and deterioration of structural mechanical properties, and achieve high yield, cost reduction, and manufacturing stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

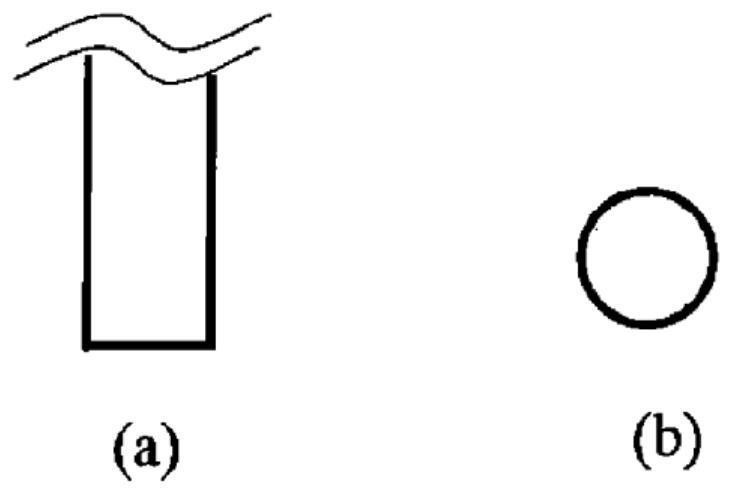

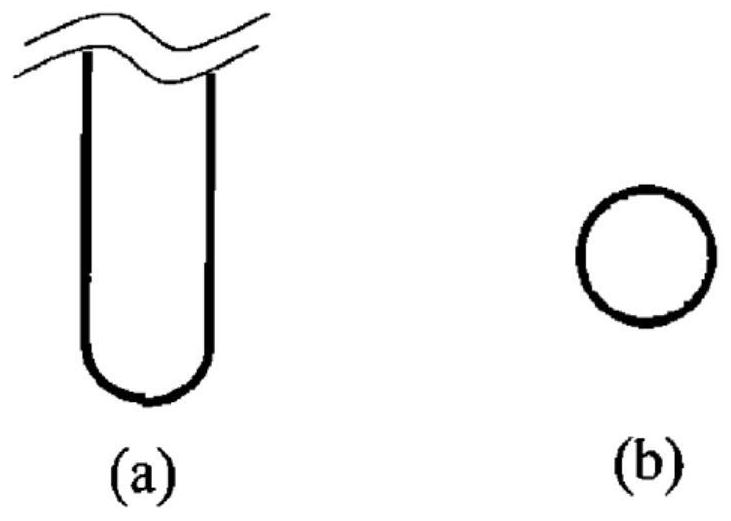

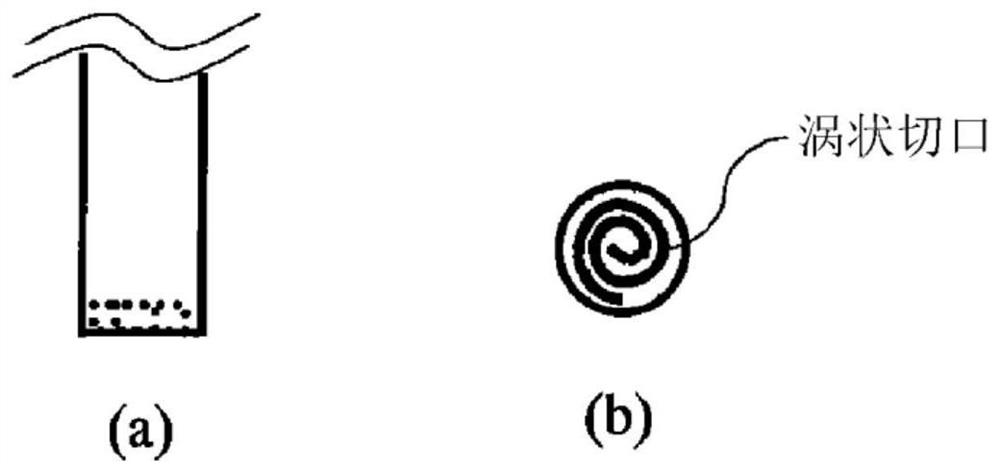

Embodiment 1

[0108] Prepare 2 sheets of 100mm×50mm×thickness 8mm plate substrates containing Ag-based alloy (composition Ag-Pd-Cu-Ge), and the cross-section is Figure 14 Grooves were processed in the shape shown, and then, Ag-based alloy joints of the same composition were used for overlay welding to fabricate Ag-based alloy joints. Figure 15 A microscope cross-sectional image of the surfacing joint is shown in . Figure 16 shown in Figure 15 Enlarged image of boxed portion of . From the enlarged image, molten structures, dendrites, and pores can be confirmed. Next, use the following conditions Figure 8 The described construction is for repairing and modifying the base material. The conditions are: use a friction tool containing an Ir-based alloy (composition Ir-Re-Zr), a diameter of 25mm, and a flat front end, and set the inclination angle θ to 3 °, use a silicon nitride plate as a backing plate, use argon as a shielding gas and flow at 25 L / min, the tool rotation speed is 3000 rp...

Embodiment 2

[0112] Prepare a sheet material with a thickness of 2.2mm containing pure Ag (purity 99.99%), after TIG (Tungsten InertGas, tungsten inert gas) welding, pass Figure 8 Repair and modification of the TIG part are carried out according to the construction described in the description. For the plate before cutting the test piece, heat treatment is performed in the atmosphere at 400°C for 2 hours in advance to eliminate the influence of strain caused by welding, repair, and modification. In addition, the test piece whose tensile strength was confirmed conformed to the 14B standard of JIS Z2241, and was uniformly formed into a thickness of 2 mm using a wire cutting device so that thickness unevenness did not occur between the dots. In addition, the repair and modification of the TIG part adopt the following conditions: use a friction tool containing an Ir-based alloy (composition Ir-Re-Zr), a diameter of 15mm, and a flat tip shape, set the inclination angle θ to 3°, and use nitroge...

reference example 1

[0114] In the same manner as in Example 2, a 2.2 mm-thick plate material containing pure Ag was prepared, and a test piece was formed in the same procedure as in Example 2 without TIG welding, repair, or modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com