Instant oat product and preparation method thereof

A technology of oat and oat products, which is applied in the field of instant oat products and its preparation, can solve the problems of unsuitable symptoms, unscientific content of formula components, and inability to meet the needs of human nutrition balance, so as to prevent obesity and hyperlipidemia Syndrome, prevention of postprandial hyperglycemia, comprehensive nutritional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

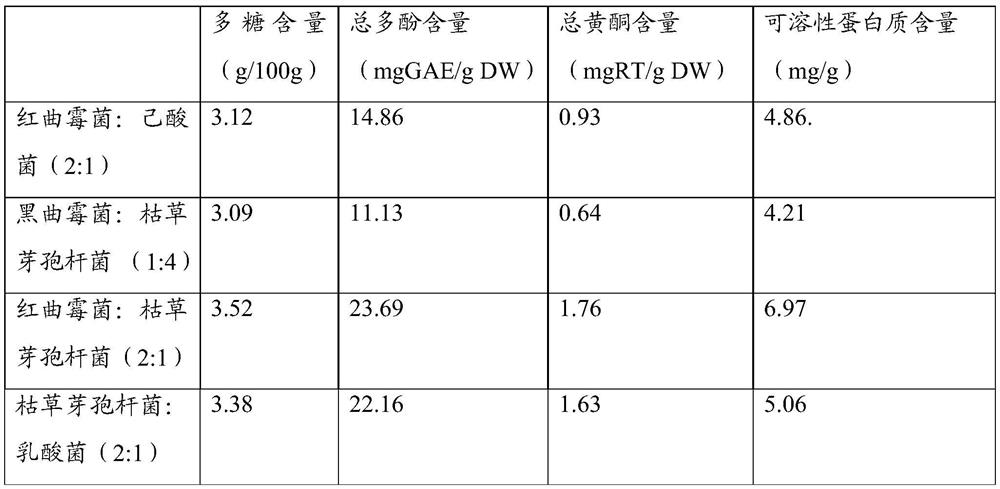

[0022] In an embodiment of the present invention, the preparation method of the fermented oats comprises the following steps:

[0023] Carry out moistening treatment to the oat grains to keep the water content at 20-35%;

[0024] Add 2-5% yeast powder and 2-5% glycerin to the moistened oat grains, and sterilize at 115-130°C; The mass percentage content;

[0025] Adding a compound strain of Bacillus subtilis and lactic acid bacteria to the sterilized oat grains for fermentation treatment, the fermentation temperature is controlled at 25-35°C, and the fermentation time is controlled at 30-45h;

[0026] The fermented oat grains are dried and ground to obtain fermented oats.

[0027] In the embodiment of the present invention, the oat grains used can be oats with hulls or naked oats. For the oats with hulls, they should be subjected to conventional cleaning, impurity removal, shelling, and depilation before the moisturizing treatment; Before the moisturizing treatment, conventi...

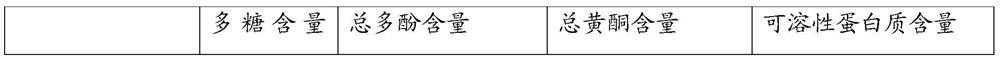

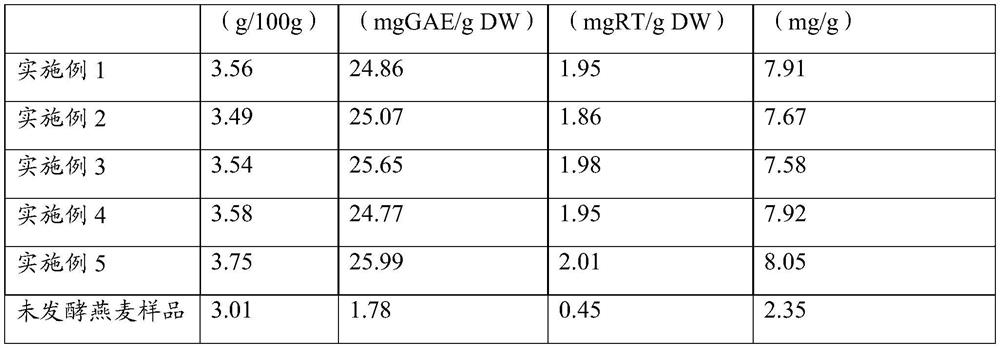

Embodiment 1

[0048] 100g oat grains are subjected to moistening treatment to keep the water content at 25%; 3.5% yeast powder and 3.5% glycerin are added to the moistened oat grains, and sterilized at 125°C for 30 minutes; after cooling to room temperature , adding a composite bacterial strain composed of Bacillus subtilis and lactic acid bacteria to the sterilized oat grains to carry out fermentation treatment, the fermentation temperature is controlled at 30°C, and the fermentation time is controlled at 40h; the weight ratio of the oat grains to the composite bacterial strains is 220:1; the inoculum ratio of Bacillus subtilis and lactic acid bacteria is 1:3; the fermented oat grains are dried and ground to obtain fermented oat flour. Take 50g of fermented oat flour and add 100mL of pure water to mix thoroughly, put it in a pot for heat treatment, so that the starch in the fermented oat flour can be gelatinized; pour the gelatinized oat flour into a tissue grinder and mix with mulberry and...

Embodiment 2

[0050] 100g oat grains are subjected to moistening treatment to keep the water content at 25%; 3.5% yeast powder and 3.5% glycerin are added to the moistened oat grains, and sterilized at 125°C for 30 minutes; after cooling to room temperature , adding a composite bacterial strain composed of Bacillus subtilis and lactic acid bacteria to the sterilized oat grains to carry out fermentation treatment, the fermentation temperature is controlled at 30°C, and the fermentation time is controlled at 40h; the weight ratio of the oat grains to the composite bacterial strains is 220:1; the inoculum ratio of Bacillus subtilis and lactic acid bacteria is 1:4; the fermented oat grains are dried and ground to obtain fermented oat flour. Take 50g of fermented oat flour and add 100mL of pure water to mix thoroughly, put it in a pot for heat treatment, so that the starch in the fermented oat flour can be gelatinized; pour the gelatinized oat flour into a tissue grinder and mix with mulberry and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com