Carbonyl reductase/isopropanol dehydrogenase co-immobilized catalyst as well as preparation method and application thereof

A technology of isopropanol dehydrogenase and isopropanol dehydrogenase crude enzyme, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., which can solve cumbersome processing, Enzyme catalysts are difficult to recycle, reuse, and increase industrial production costs, etc., to achieve high catalytic efficiency, major industrial application value, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, preparation of carbonyl reductase / isopropanol dehydrogenase co-immobilized catalyst

[0039] Weigh 5g of polyvinyl alcohol, 3g of polyethylene glycol and 35mL of water into a reaction flask, heat until the solution is clear, cool down to below 50°C, add 10mL of carbonyl reductase crude enzyme solution (15% w / v) and 5mL of iso Propanol dehydrogenase crude enzyme solution (15% w / v), mix well. After mixing, drop the solution onto the polyethylene film with a syringe, and then place it in a blast oven at 35-40°C for 1 hour to obtain the carbonyl reductase / isopropanol dehydrogenase co-immobilized catalyst, which is stored in Store at 4°C for later use.

Embodiment 2

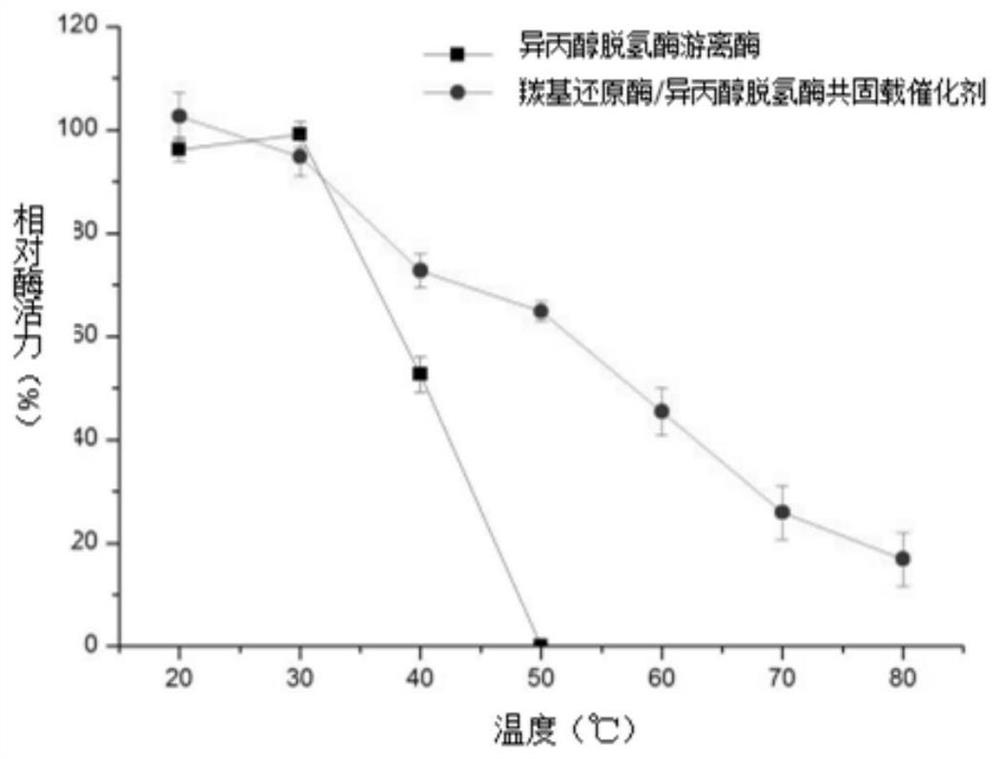

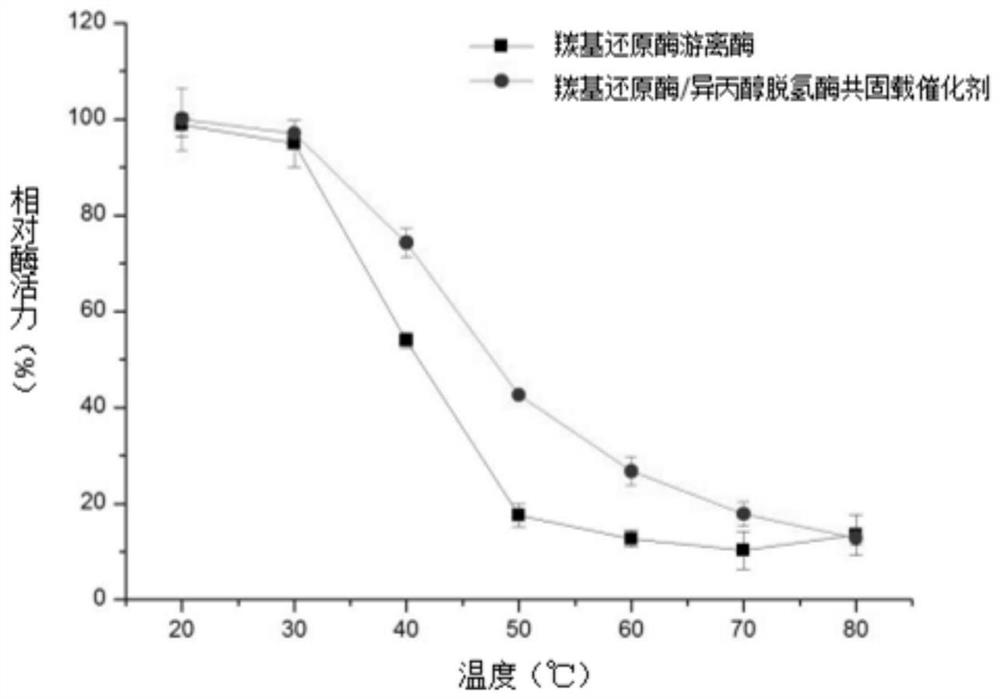

[0040] Example 2, Study on Thermal Stability of Carbonyl Reductase / Isopropanol Dehydrogenase Co-immobilized Catalyst

[0041] Get carbonyl reductase free enzyme (crude enzyme liquid), isopropanol dehydrogenase free enzyme (crude enzyme liquid) and the carbonyl reductase / isopropanol dehydrogenase co-immobilized catalyst that embodiment 1 makes, respectively in 20 ℃, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C for 30 minutes, and then measure the enzyme activity respectively, with the highest activity as 100%, measure in parallel three times, and make the corresponding temperature stability curve, as figure 1 and 2 shown.

[0042] Carbonyl reductase enzyme activity assay method: take a certain amount of carbonyl reductase free enzyme or immobilized enzyme, add to the phosphate buffer solution (100 mM, pH 7.5) containing substrate (10 mM), NADPH (0.24 mM) ), shake for 1 min, centrifuge, take the supernatant to measure the absorbance change at 340 nm, and calculate the enzyme activity p...

Embodiment 3

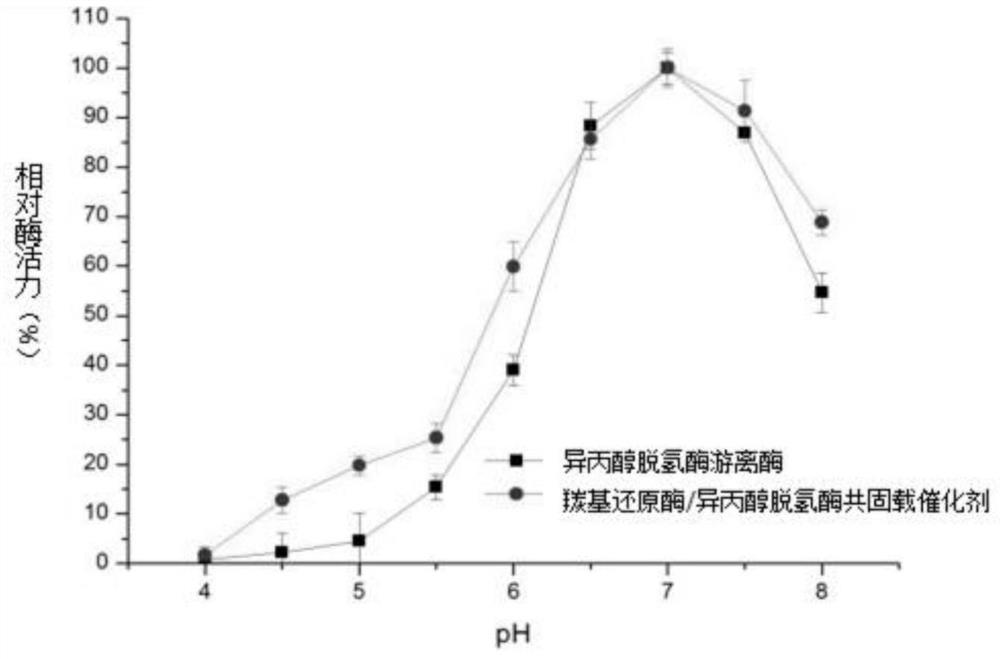

[0045] Example 3, Study on pH Stability of Carbonyl Reductase / Isopropanol Dehydrogenase Co-immobilized Catalyst

[0046] Get carbonyl reductase free enzyme, isopropanol dehydrogenase free enzyme and the carbonyl reductase / isopropanol dehydrogenase co-immobilized catalyst that embodiment 1 makes, add to pH 4,5,6,7,8 Incubate in a 30°C water bath for 5 minutes, and then measure the enzyme activity, with the highest activity as 100%, measure three times in parallel, and make the corresponding pH stability curve, as shown in image 3 and 4 shown.

[0047] Depend on image 3 and 4 It can be seen that, for isopropanol dehydrogenase, both the immobilized enzyme and the free enzyme lose their activity at pH=4, and in the case of pH=5-8, the pH stability of the immobilized enzyme is better than that of the free enzyme. improved. For carbonyl reductase, the pH stability of the immobilized enzyme was lower than that of the free enzyme under acidic conditions; however, the pH stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com