Preparation method of expanded graphite cerium oxide or graphene cerium oxide composite material

A technology of expanded graphite and composite materials, used in the preparation/processing of cerium oxide/cerium hydroxide, rare earth metal compounds, graphene, etc., can solve the problems of difficult mixing and firm bonding, and achieve easy scale-up and mass production. , the process is simplified, the material structure is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 10g of flake graphite into a beaker, add 200ml of 60% sulfuric acid solution, stir in a 40°C water bath for 10min, gradually add 1g of potassium permanganate solid, stir in a 40°C water bath for 90min, collect the precipitate by filtration, and wash the precipitate until the pH value is 5-7, drying the precipitate to obtain expandable graphite.

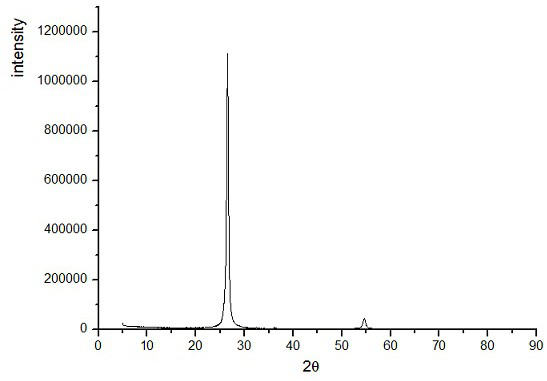

[0032] Take 1g of expandable graphite and pour it into 100mL of cerium chloride solution (1g / L), stir at room temperature for 3 hours, then evaporate the water to dryness while heating while stirring, and obtain the graphite intercalation compound intercalated with cerium chloride, put it in 600℃ The muffle furnace is used for 2 minutes, graphite expands, cerium chloride is decomposed into cerium oxide, and expanded graphite / cerium oxide composite material is generated.

[0033] 1 g of expanded graphite / cerium oxide composite was dispersed in 100 mL of N,N-dimethylformamide (DMF), and the graphene / cerium oxide composite was...

Embodiment 2

[0035] Put 10g of flake graphite into a beaker, add 100ml of 80% sulfuric acid solution, stir in a 40°C water bath for 10min, gradually add 5g of potassium permanganate solid, stir in a 40°C water bath for 90min, filter and collect the precipitate, and wash the precipitate until the pH value is 5-7, drying the precipitate to obtain expandable graphite.

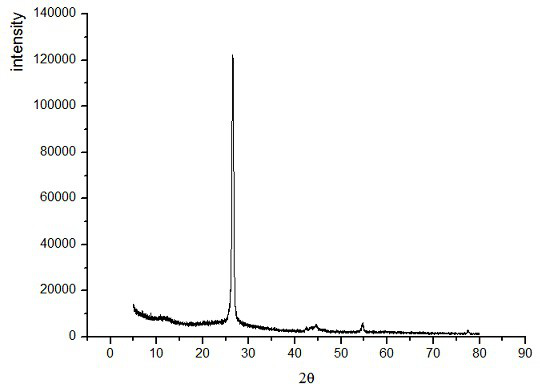

[0036] Take 1g of expandable graphite and pour it into 40mL of cerium chloride solution (20g / L), stir at room temperature for 3 hours, then evaporate the water to dryness while heating while stirring, and obtain the graphite intercalation compound intercalated with cerium chloride, put it in 700℃ In the muffle furnace for 90s, the graphite expands, and the cerium chloride is decomposed into cerium oxide, forming an expanded graphite / cerium oxide composite material.

[0037] 1 g of expanded graphite / cerium oxide composite was dispersed in 100 mL of N,N-dimethylformamide (DMF), and the graphene / cerium oxide composite was obtaine...

Embodiment 3

[0039] Put 10g flake graphite into a beaker, add 50ml of 90% sulfuric acid solution, stir in a 40°C water bath for 10min, gradually add 8g of potassium permanganate solid, stir in a 40°C water bath for 90min, filter and collect the precipitate, and wash the precipitate until the pH value is 5-7, drying the precipitate to obtain expandable graphite.

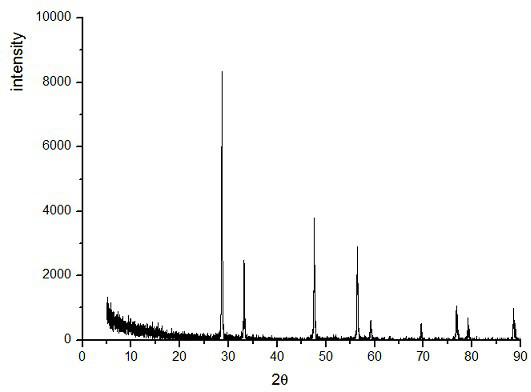

[0040] Take 1g of expandable graphite and pour it into 20mL of cerium chloride solution (100g / L), stir at room temperature for 3 hours, then evaporate the water to dryness while heating while stirring to obtain graphite interlayer compound intercalated with cerium chloride, and put it in 1000℃ In the muffle furnace for 30s, graphite expands, cerium chloride is decomposed into cerium oxide, and expanded graphite / cerium oxide composite material is generated.

[0041] 1 g of expanded graphite / cerium oxide composite was dispersed in 100 mL of N,N-dimethylformamide (DMF), and the graphene / cerium oxide composite was obtained by ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com