Tar-free activated carbon preparation method

A kind of activated carbon preparation, tar-free technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve pollution, hazards and other problems, achieve the effect of solving environmental pollution problems, improving working environment, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

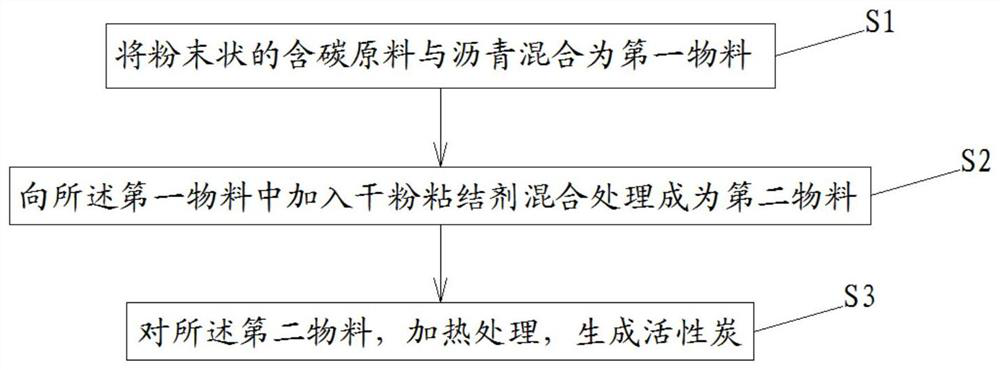

[0054] Such as figure 1 Shown, according to one embodiment of the present invention, a kind of tar-free activated carbon preparation method of the present invention comprises:

[0055] S1. Mixing the powdery carbonaceous raw material and asphalt into the first material;

[0056] S2. adding a dry powder binder to the first material and mixing it into a second material;

[0057] S3. Heat-treat the second material to generate activated carbon.

[0058] According to one embodiment of the present invention, in step S1, the carbon-containing raw material is one or more of anthracite, semi-coal, bituminous coal, wood, plant branches, and activated carbon sieve material. In this embodiment, the carbon-containing raw materials are mixed according to a certain ratio of several selected carbon-containing raw materials, wherein the bituminous coal includes coking coal and weakly caking coal. Certainly, other carbon-containing raw materials may also be used as the carbon-containing raw ...

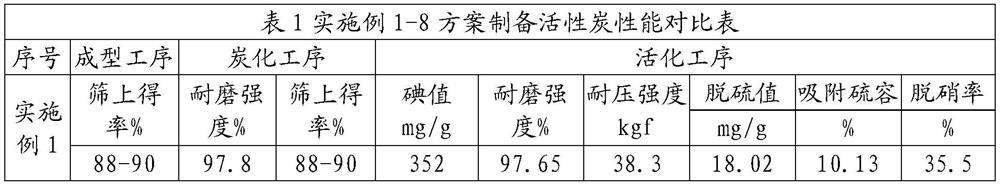

Embodiment 1

[0086] Put 7wt% weak caking coal, 23wt% coking coal and 70wt% semi-coke into coal powder with a particle size of 325 mesh and put it into a kneader with a temperature above 80°C, add 18wt% coal tar and mix for 15-20min, then add water Continue mixing for 10-15 minutes, and the molding material is prepared by the granulator, and the molding material is put into the carbonization furnace with the temperature at the end of the furnace at 300 to 350 °C, the temperature in the furnace at 400 to 500 °C, and the temperature at the furnace head at 700 to 800 °C Heat treatment, and the speed of the carbonization furnace is controlled at 1.0-2.5 rpm, the heating rate is controlled at 5-20°C / min, the material is carbonized and then put into the activation furnace, and the activator (water vapor) is mixed with the activator (water vapor) at 850-980°C Activation reaction is carried out to generate activated carbon, and finally sieved to obtain the product activated carbon.

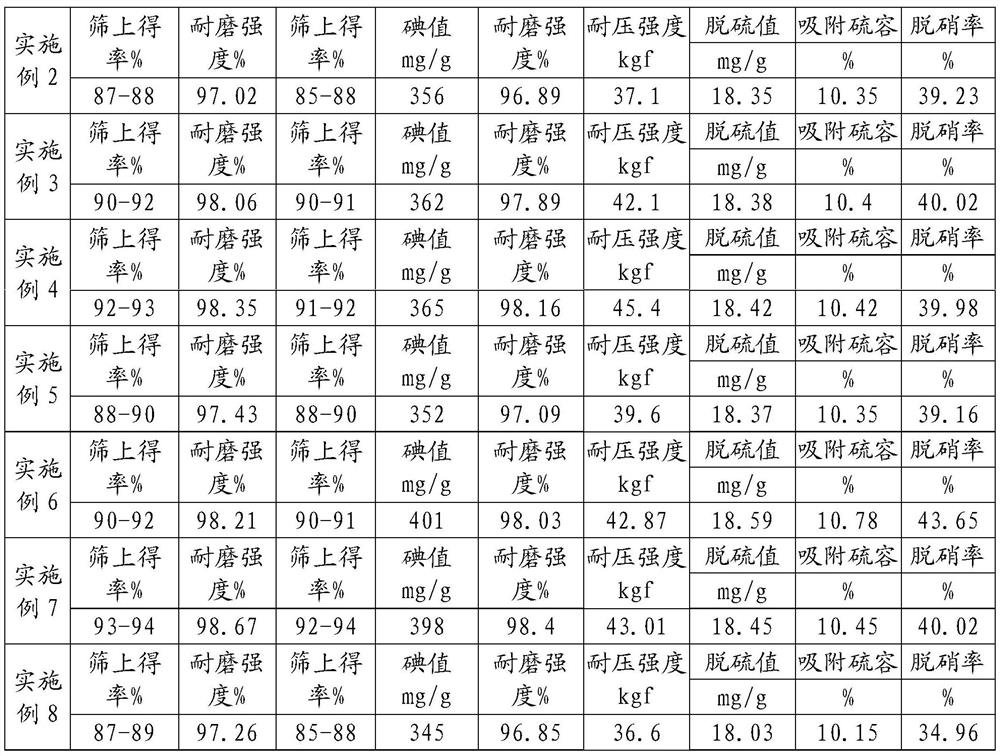

Embodiment 2

[0088] Make 12wt% weak caking coal, 15wt% coking coal, 10wt% bitumen and 63wt% semi-coke into coal powder with a particle size of 325 mesh (i.e. the first material) and put it in a kneader at a temperature of 30-50°C for 15-20min , the preparation mass ratio is the aqueous solution of 3wt% binding agent (comprising one or more mixtures of guar gum, xanthan gum, sodium alginate), and then takes the binding agent aqueous solution according to the 10-35wt of the first material quality %, continue to mix with the first material in the kneader for 10-15 minutes, after the molding material (ie the second material) is obtained by the granulator, the molding material is put into the tail of the furnace at a temperature of 300 to 350 ° C, and the temperature in the furnace is 400 to 500°C, the furnace head temperature is heated in a carbonization furnace at 700 to 800°C, and the speed of the carbonization furnace is controlled at 1.0-2.5 rpm, and the heating rate is controlled at 5-20°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com