Integrated vertical high-concentration sulfate wastewater treatment device

A waste water treatment and sulfate technology, applied in anaerobic digestion treatment, biological water/sewage treatment, degassed water/sewage treatment, etc. Effects and other issues, to achieve the effect of reducing energy consumption, reducing floor space, and ensuring activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

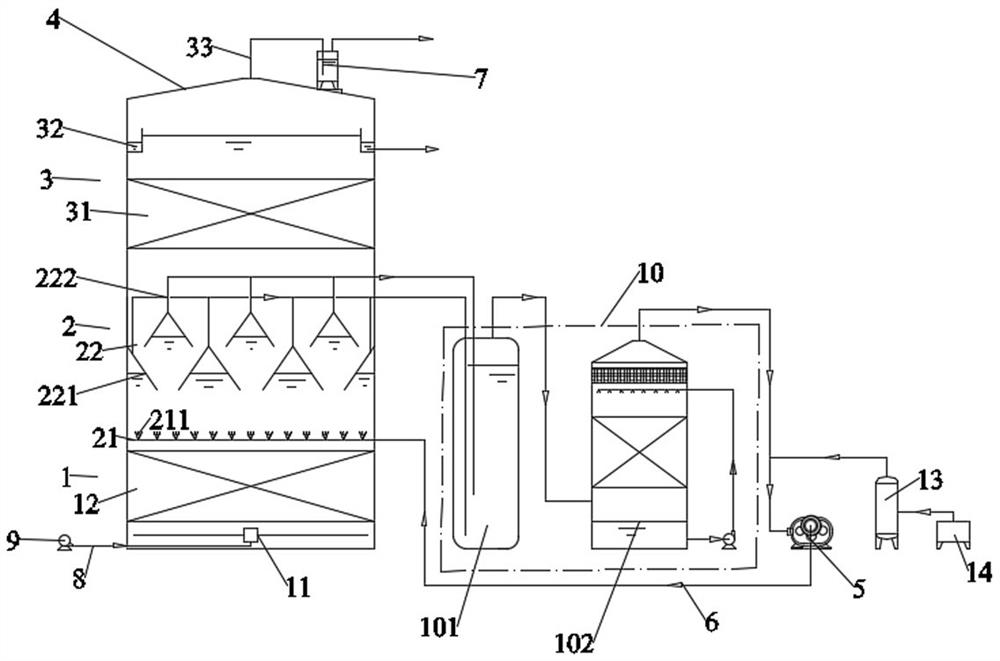

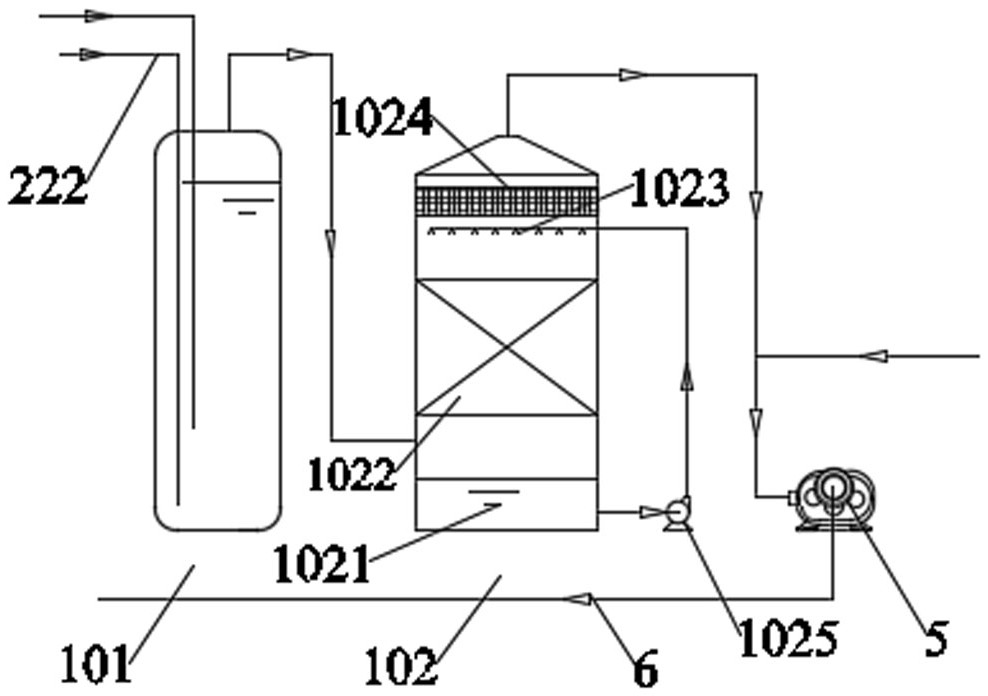

[0026] Such as figure 1 As shown, an integrated vertical high-concentration sulfate wastewater treatment device includes a hydrolysis acidification reaction section 1 for reducing sulfate radicals in high-concentration sulfate wastewater, a hydrogen sulfide stripping section 2 and a hydrogen sulfide stripping section for reducing the concentration of hydrogen sulfide. A methanogenic reaction section 3 for removing organic matter in wastewater and a tank body 4 for accommodating the hydrolytic acidification reaction section 1, the hydrogen sulfide stripping section 2 and the methanogenic reaction section 3, the hydrolysis acidification reaction section 1 is set In the lower section of the tank body 4, it includes a bottom water distribution pipe 11 for uniformly spreading high-concentration sulfate wastewater and a first packing layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com