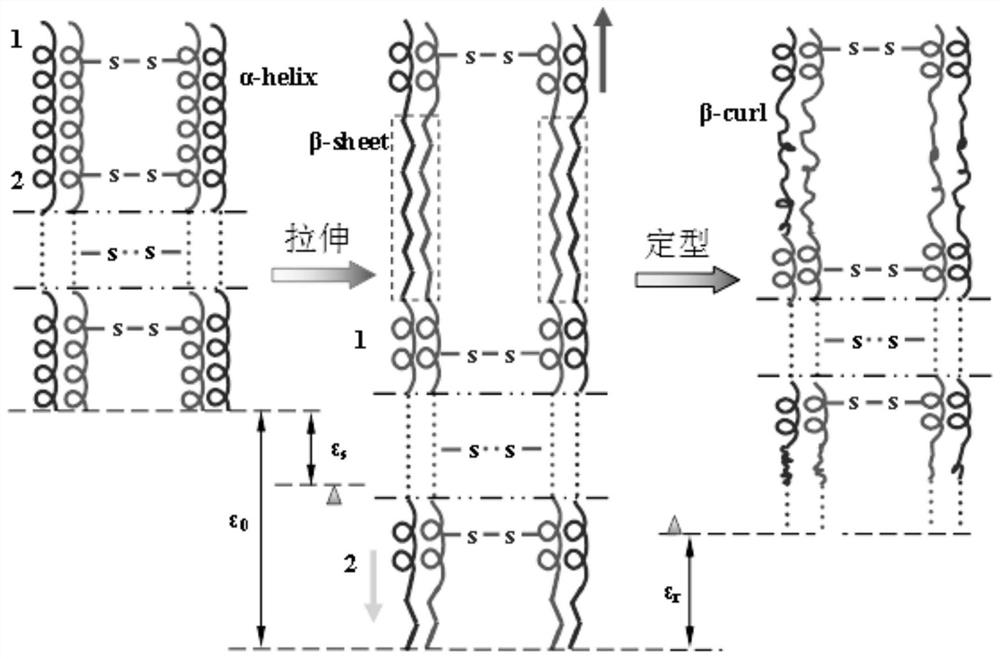

Soft wool fabric of fine wool based on beta folding to alpha spiral transition and preparation thereof

A technology of α-helix and β-folding, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problem of low thinning efficiency of wool thinning materials, achieve good elasticity, barrier-free movement, and improve thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

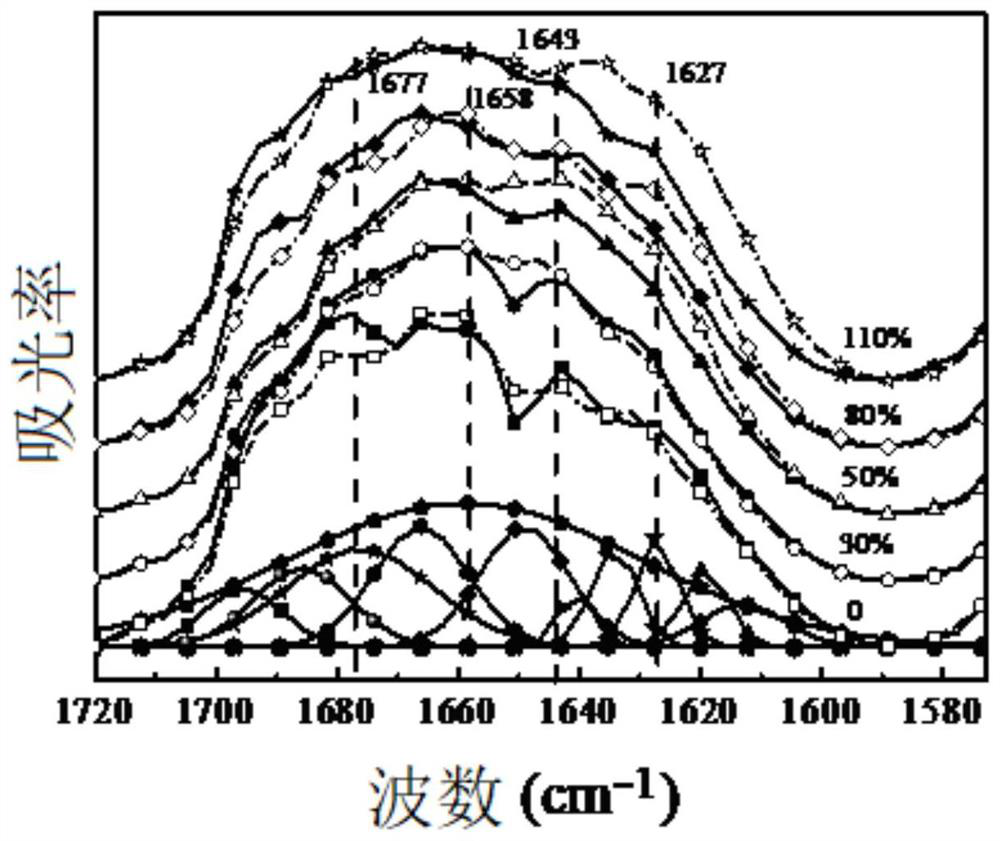

Method used

Image

Examples

Embodiment 1

[0026] The wool fibers were pretreated in a 3wt% sodium bisulfite treatment solution at 75°C to open the disulfide bonds and salt bonds between the helical macromolecules, and then stretched on a stretching machine with a twist of 30 twists / m , the stretching speed is 50% / min, the stretching ratio is 40%, and the tops after stretching and setting are subjected to setting treatment in 6.5% potassium persulfate and 1.5% zinc acetate solution. The obtained 40% stretched wool yarn is then interwoven into a fabric on a loom according to a one-upper-down plain weave. The warp and weft densities of the fabric are 350 / 10cm and 280 / 10cm respectively, and then the fabric is dyed at 115°C, the fabric will obtain a shrinkage rate of 10%, and the structure will become tight and elastic.

Embodiment 2

[0028] The wool fiber was pretreated in a 5wt% sodium bisulfite treatment solution at 70°C to open the disulfide bonds and salt bonds between the helical macromolecules, and then stretched on a stretching machine with a twist of 15 twists / m , the stretching speed is 30% / min, the stretching ratio is 90%, and the tops after stretching and shaping are subjected to setting treatment in 5.5% potassium persulfate and 2.5% zinc acetate solution. Then, the obtained wool yarn with 60% elongation rate is interwoven into a fabric on a loom according to a plain weave one above the other. The warp and weft densities of the fabric were 350 / 10cm and 280 / 10cm respectively, and then the fabric was dyed at 110°C, the fabric obtained a shrinkage rate of 15%, and the structure became tight and elastic.

Embodiment 3

[0030] The wool fibers were pretreated in a 3wt% sodium bisulfite treatment solution at 75°C to open the disulfide bonds and salt bonds between the helical macromolecules, and then stretched on a stretching machine with a twist of 30 twists / m , the stretching speed is 50% / min, the stretching rate is 20%, and the tops after stretching and setting are subjected to setting treatment in 6.5% potassium persulfate and 1.5% zinc acetate solution. Then, the obtained wool yarn with a stretch ratio of 20% is interwoven into a fabric on a loom according to a plain weave one above the other. The warp and weft densities of the fabric were 350 / 10cm and 280 / 10cm respectively, and then the fabric was dyed at 105°C, the fabric obtained a shrinkage rate of 5%, and the structure became tight and elastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap