Integrated interconnection structure of self-airtight packaging function module and implementation method

A technology of hermetic packaging and functional modules, applied in the direction of electrical components, circuit heating devices, electrical connection printing components, etc., can solve the problems that do not involve the electrical interconnection of multi-functional circuit modules, micro-channel interface connection, etc., to improve the electromagnetic shielding effect , increase the large-area welding area, and improve the reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

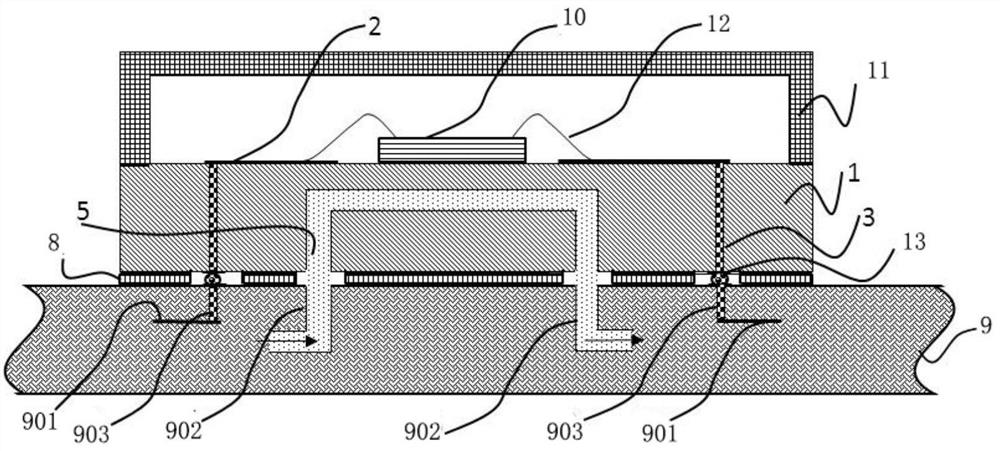

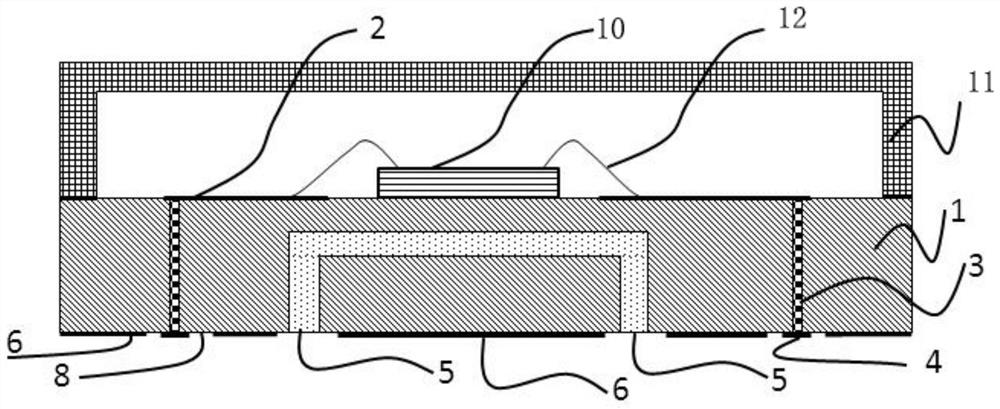

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

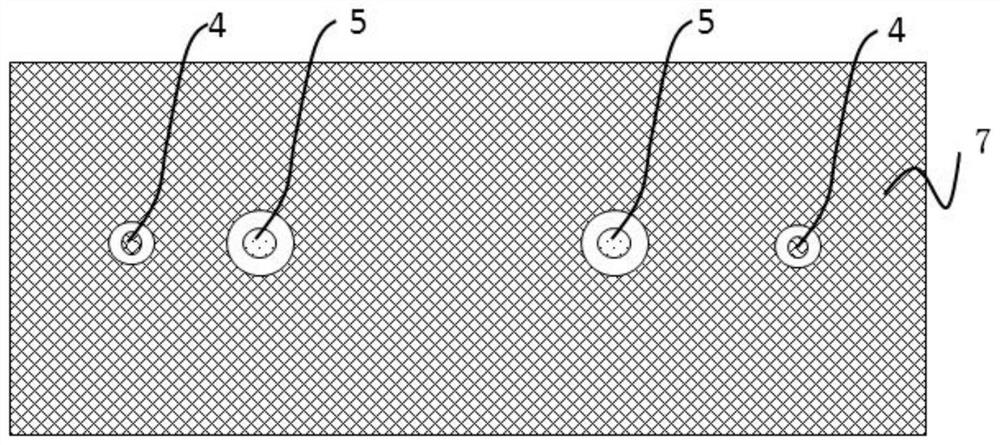

[0033] Such as figure 1 As shown, an integrated interconnection structure of self-hermetic packaging functional modules, including self-hermetic packaging functional modules, a structural transfer layer, and a system motherboard; the system motherboard is provided with a conductive film layer for electrical interconnection and Signal connection hole, the conductor film layer on the system motherboard is connected to the signal connection hole;

[0034] The self-hermetic packaging functional module includes a circuit substrate, a chip assembled on the front of the circuit substrate, and a self-hermetic packaging cover packaged on the front of the circuit substrate. The left and right sides of the circuit substrate are respectively provided with through connection holes, and the connection holes on the front of the substrate are A conductive film layer is provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com