Deep cleaning mask and production technology thereof

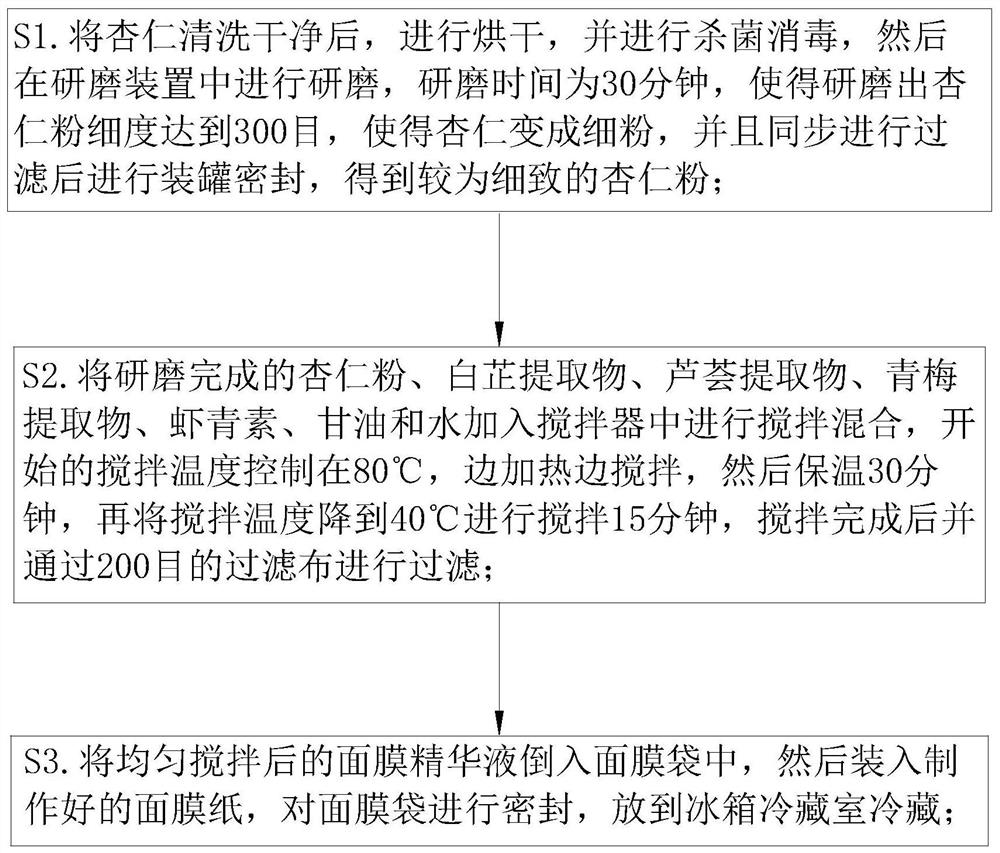

A production process and surface cleaning technology, applied in cosmetics, preparations for skin care, grain treatment, etc., can solve problems such as affecting the quality of masks, reducing work efficiency, and single grinding method, so as to improve grinding quality, improve work efficiency, increase Effect of grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

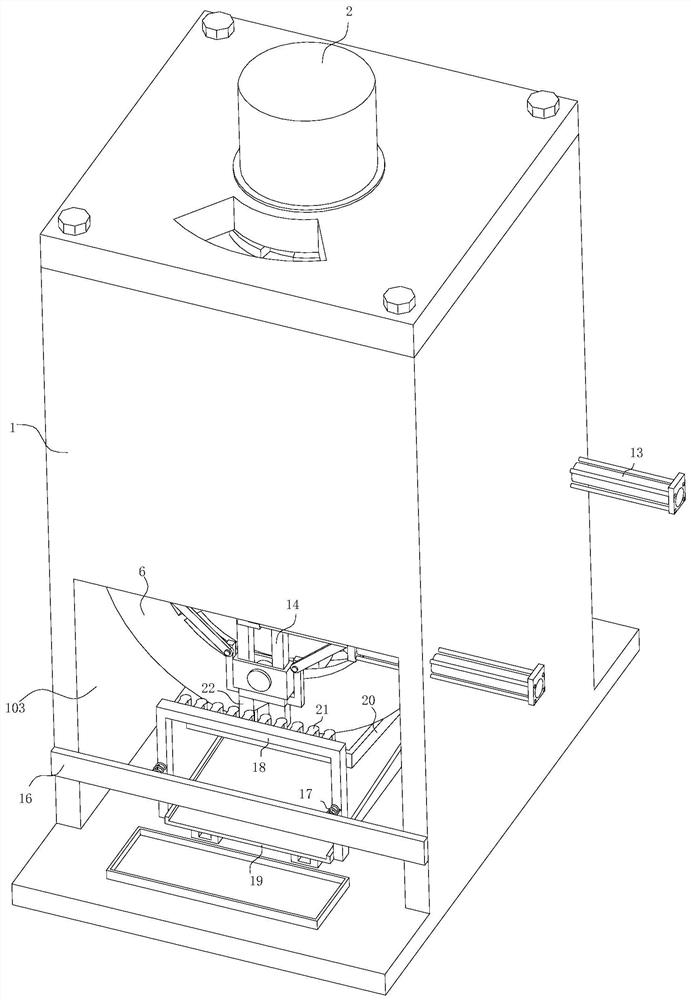

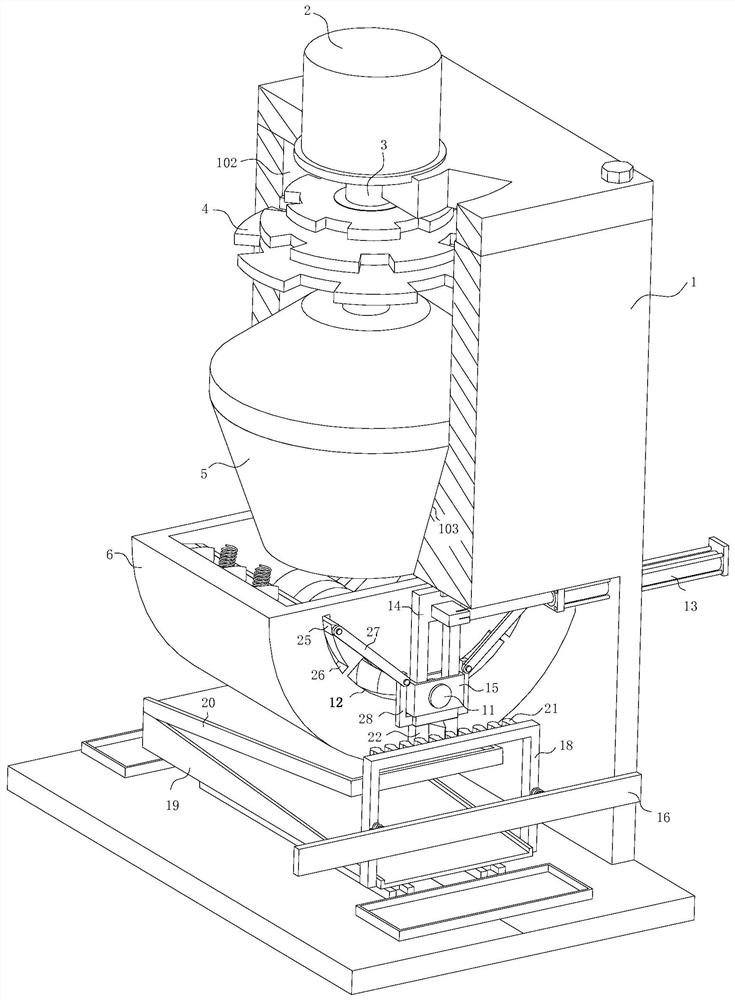

[0035] As an embodiment of the present invention, the front of the grinding box 1 is fixedly connected with a baffle 16 corresponding to the position of the filter cavity 103; both sides of the back of the baffle 16 are fixedly connected with two symmetrically arranged support springs 17 The rear ends of the four supporting springs 17 are jointly fixedly connected with a U-shaped support frame 18; the two ends of the bottom of the U-shaped support frame 18 are jointly fixedly connected with a filter screen 20; the bottom of the filter screen 20 is fixedly connected with a Drainage bucket 19; the bottom of the shunt is slidingly connected to the bottom of the filter chamber 103 inner wall; during work, the almond powder passing through the filter plate 7 has obtained a layer of filtration, and in the extrusion process, the filter plate 7 is in the second grinding roller 9 Slight deformation occurs under extrusion, causing the filter hole to become larger instantly, and the almon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com