Acrylic acid purification and light component removal tower

A light removal tower and acrylic acid technology, which is applied in the field of light removal tower, can solve the problems of reducing the production efficiency of acrylic acid, the long time for separation of toluene and water, and increasing the production cycle of acrylic acid, so as to reduce the probability, increase the speed, and increase the particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

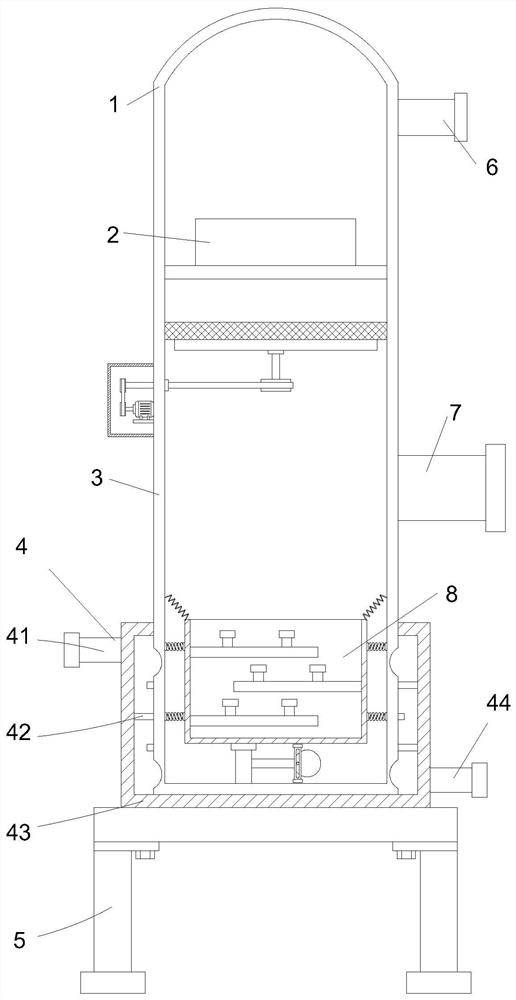

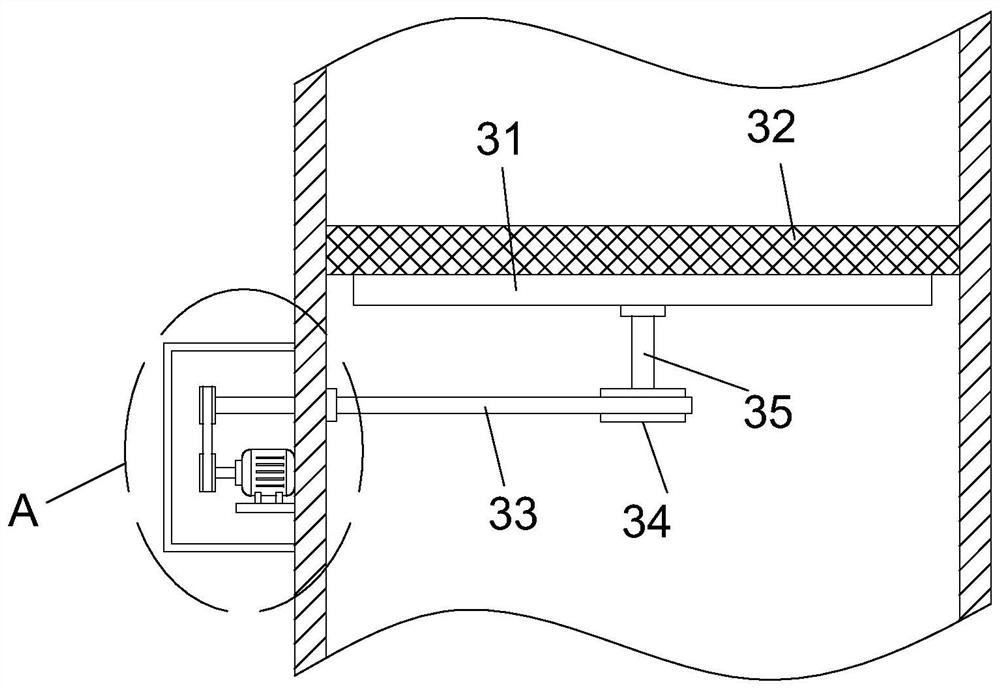

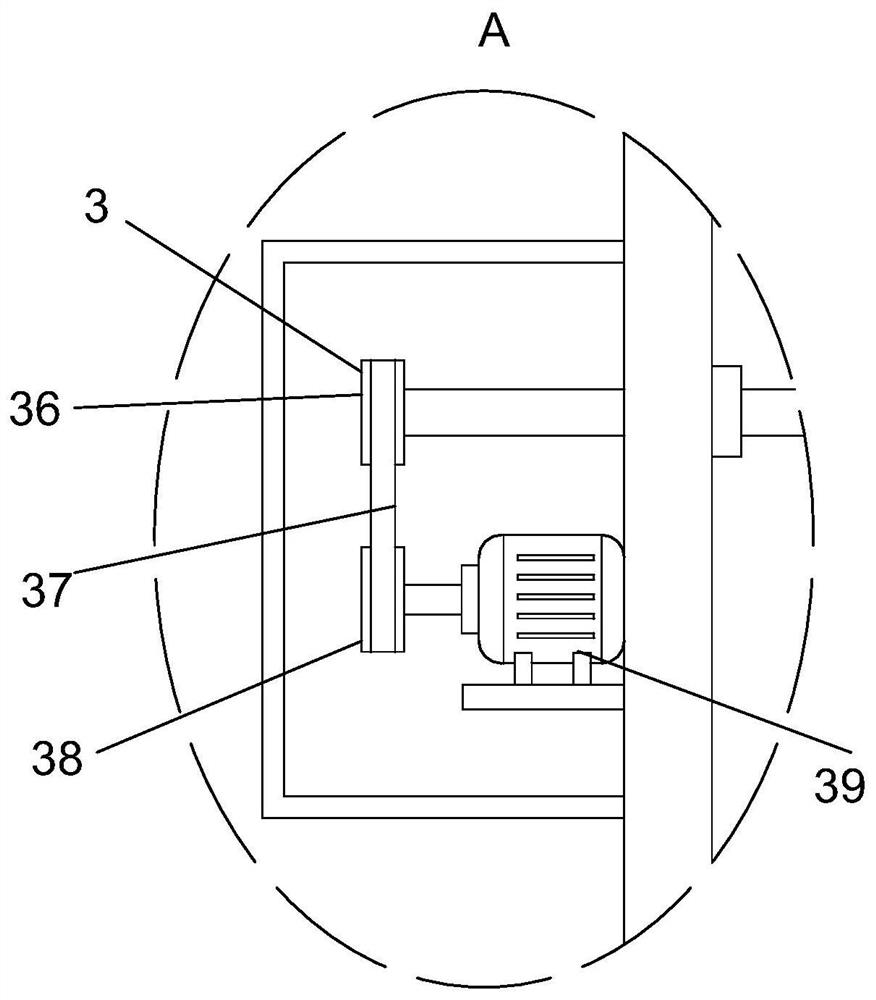

[0020] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , an acrylic acid purification and light removal tower, comprising an acrylic acid purification and light removal tower body 1, a rectification section sieve plate 2, a filter mechanism 3, a cooling mechanism 4 and a separation mechanism 8, the middle part of the acrylic acid purification and light removal tower body 1 is fixedly connected with The feed pipe 7 communicating with its inside, and the top of the acrylic acid purification and lightening tower body 1 is provided with an outlet pipe 6; The plate 2 is positioned above the feed pipe 7; the filter screen mechanism 3 is installed in the acrylic acid purification light removal tower body 1, and the filter screen mechanism 3 is positioned above the feed pipe 7; the top of the filter screen mechanism 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com