A coal-fired boiler flue gas scr dry denitrification device

A technology for coal-fired boilers and flue gas, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of low denitrification efficiency of denitrification devices, achieve the effects of increasing contact, facilitating oxidation and reduction, and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present application will be further described in detail below with reference to the accompanying drawings.

[0043] The embodiment of the present application discloses a SCR dry denitration device for flue gas of a coal-fired boiler.

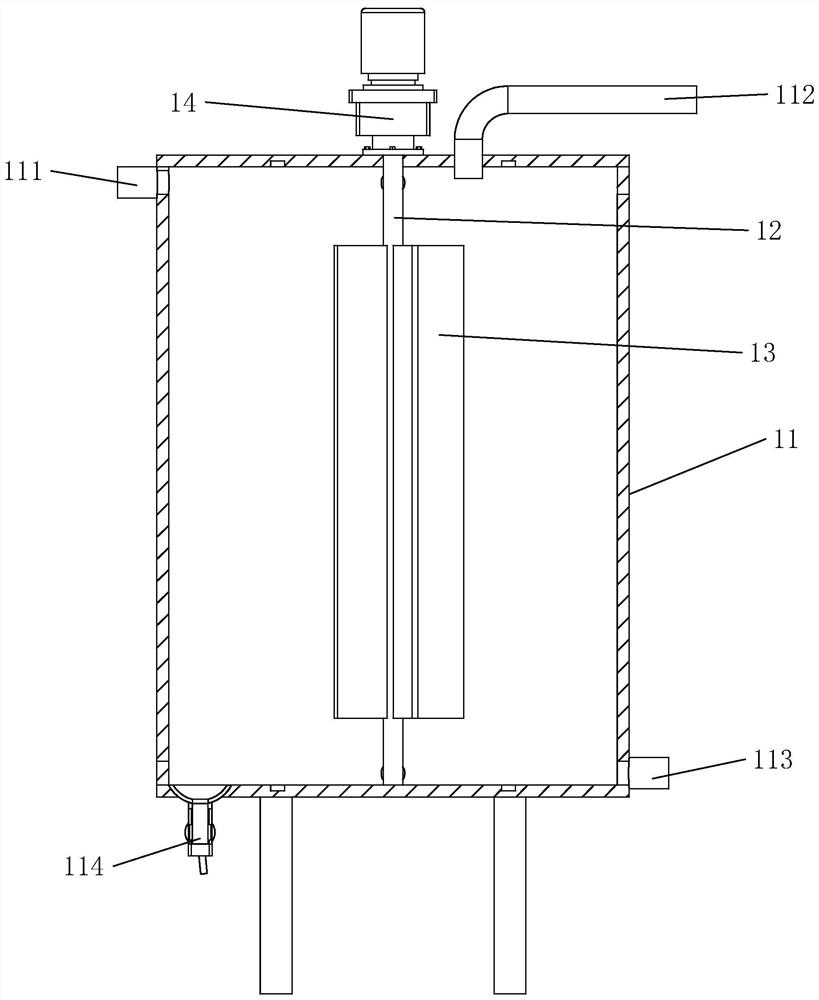

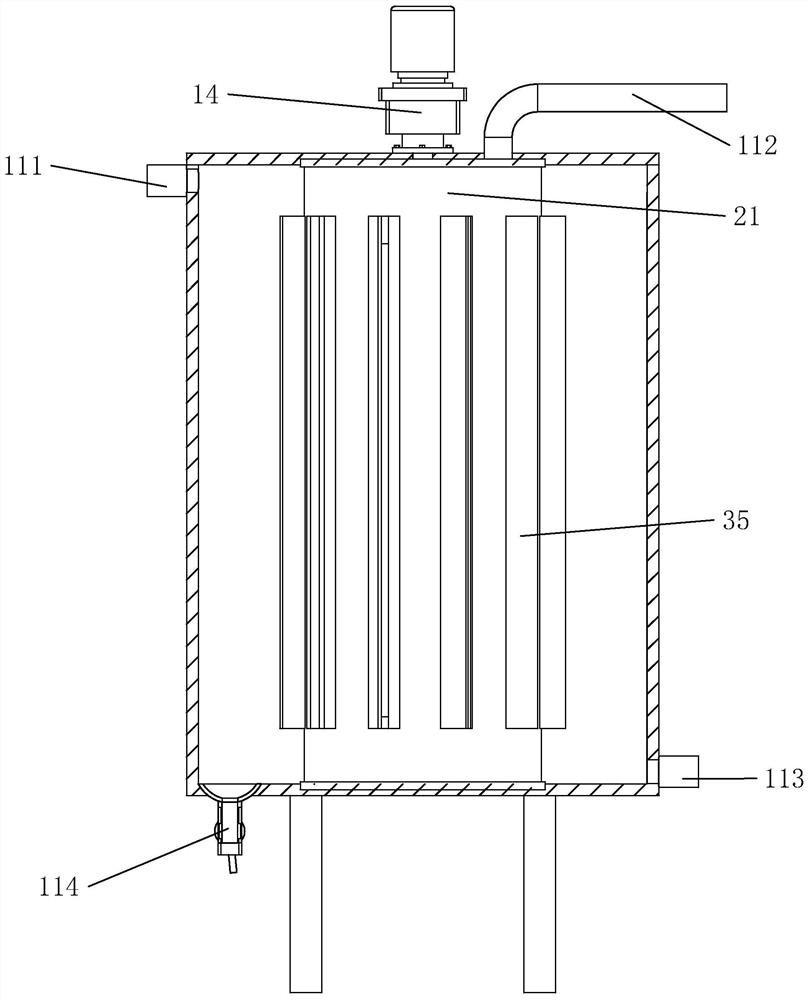

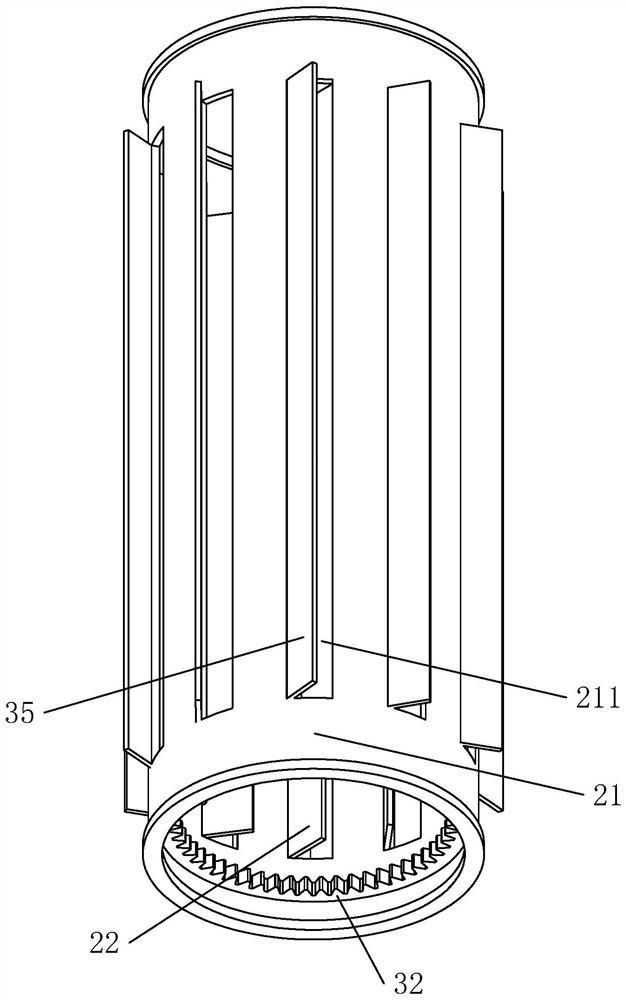

[0044] refer to figure 1 The denitration device includes a tank 11 , a rotating shaft 12 rotatably connected in the tank 11 , blades 13 arranged on the rotating shaft 12 , a driving device 14 arranged on the tank 11 , and a catalyst distributed in the tank 11 . The tank body 11 is provided with a flue gas inlet 111 and a flue gas outlet 113 for the entry and exit of the flue gas, and the tank body 11 is also provided with an oxidizing gas inlet 112 for the entry of the oxidizing gas, as well as an outlet for degassing and water droplets. Water drop vent 114 . The catalyst is evenly distributed on the inner wall of the tank 11 and on the surface of the blades. After the oxidizing gas and flue gas are introduced into the tank 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com