Preparation method of metal phase vanadium/molybdenum disulfide/carbon cloth sodium ion battery negative electrode material

A sodium-ion battery, molybdenum disulfide technology, applied in battery electrodes, secondary batteries, negative electrodes, etc., can solve the problems of poor cycle performance, easy material agglomeration, etc., to improve electrical conductivity, good electrical conductivity, and good development prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 50 mL of concentrated nitric acid into the inner lining of the reaction kettle, arrange the carbon in the inner lining of the reaction kettle, heat at 90°C for 8 h, wash and dry it for later use. Dissolve 60 mg of ammonium molybdate tetrahydrate, 1 g of L-cysteine, and 9 mg of sodium vanadate in 70 mL of deionized water. Pour the mixed solution into the lining of the reactor, add acid-treated carbon cloth material with a size of 3 cm*5 cm, and put it in an oven at 220 °C for 24 h. After naturally cooling to room temperature, the carbon cloth material was taken out, washed by centrifugation, and dried at 60°C. Obtain metal phase vanadium / molybdenum disulfide / carbon cloth material;

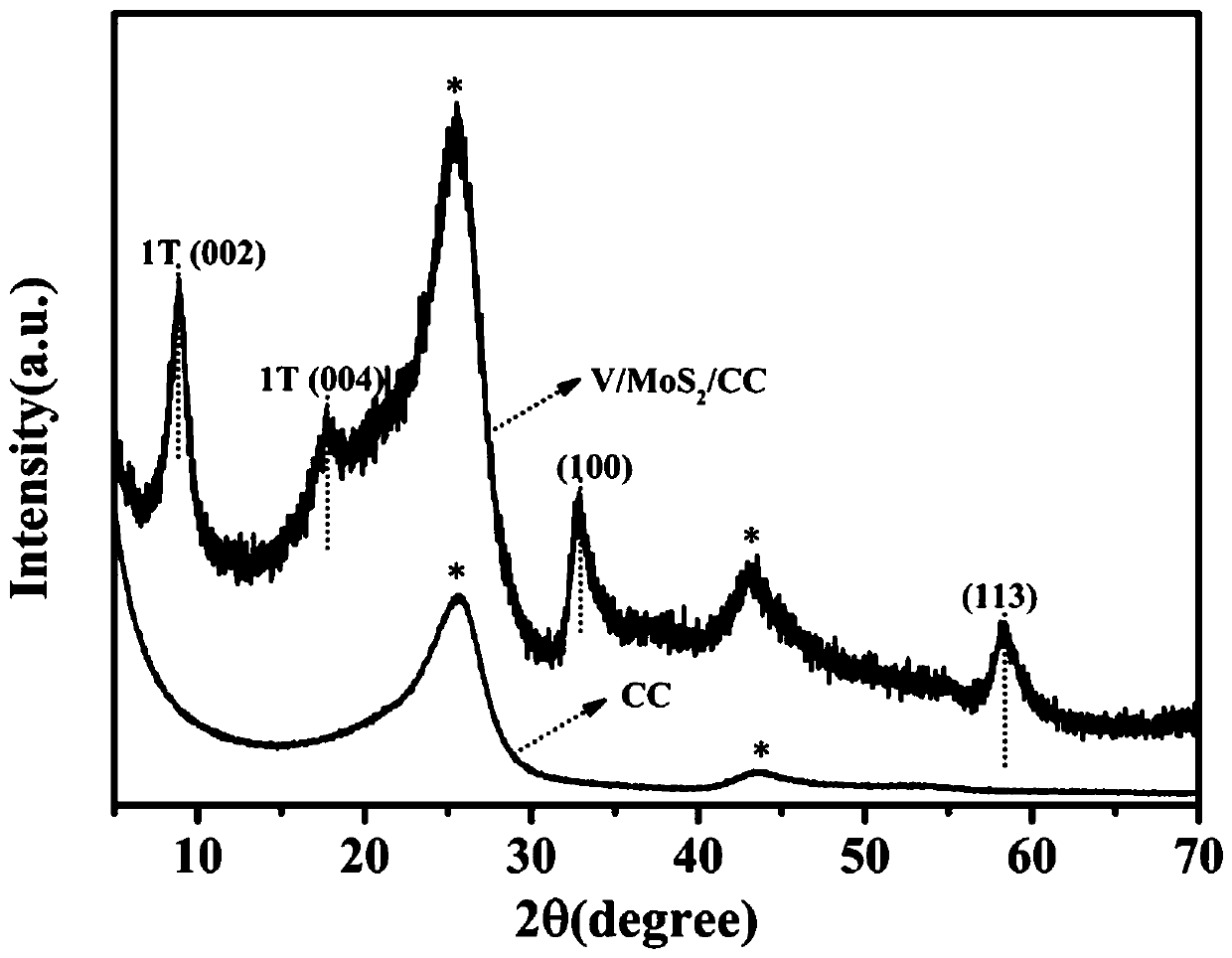

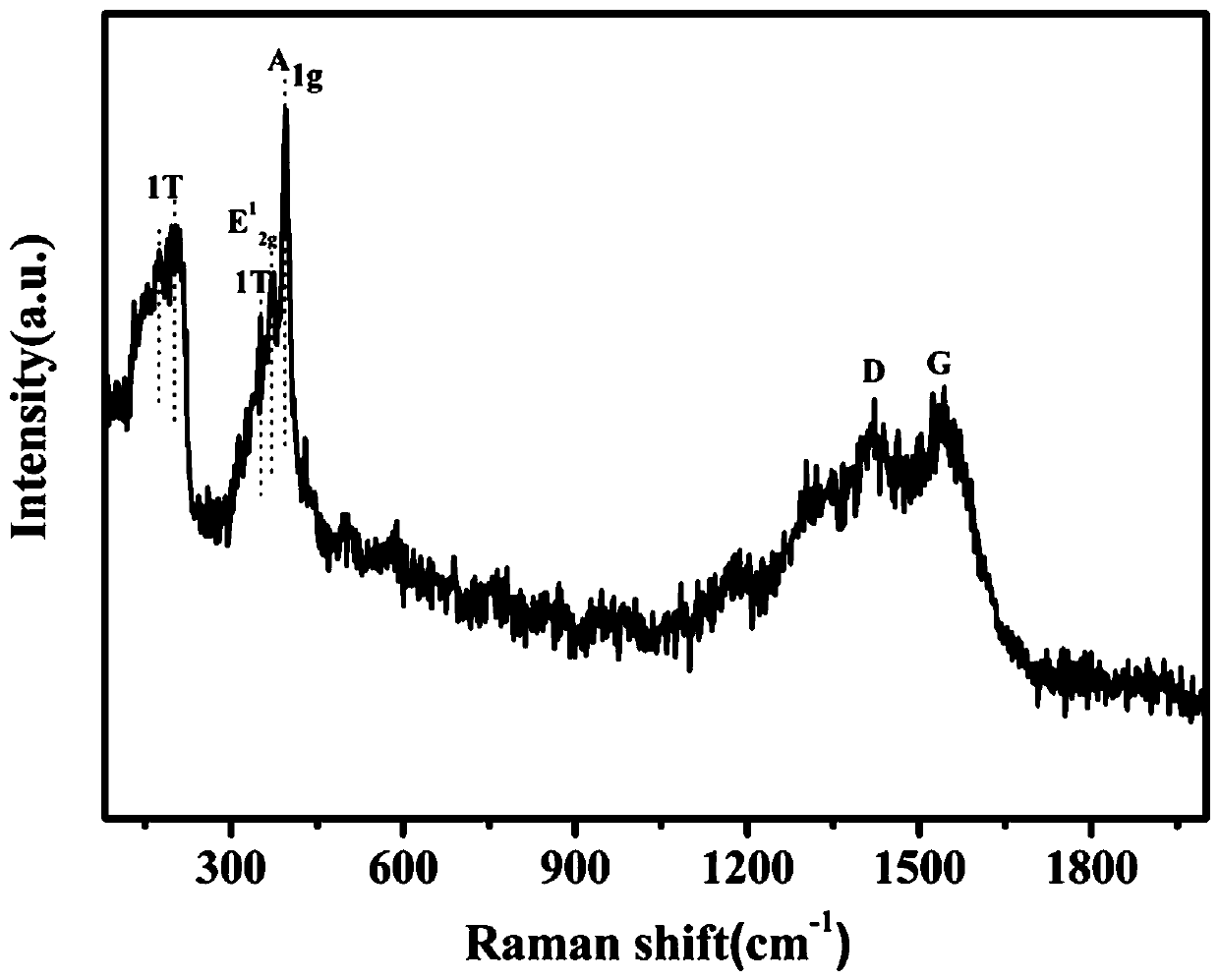

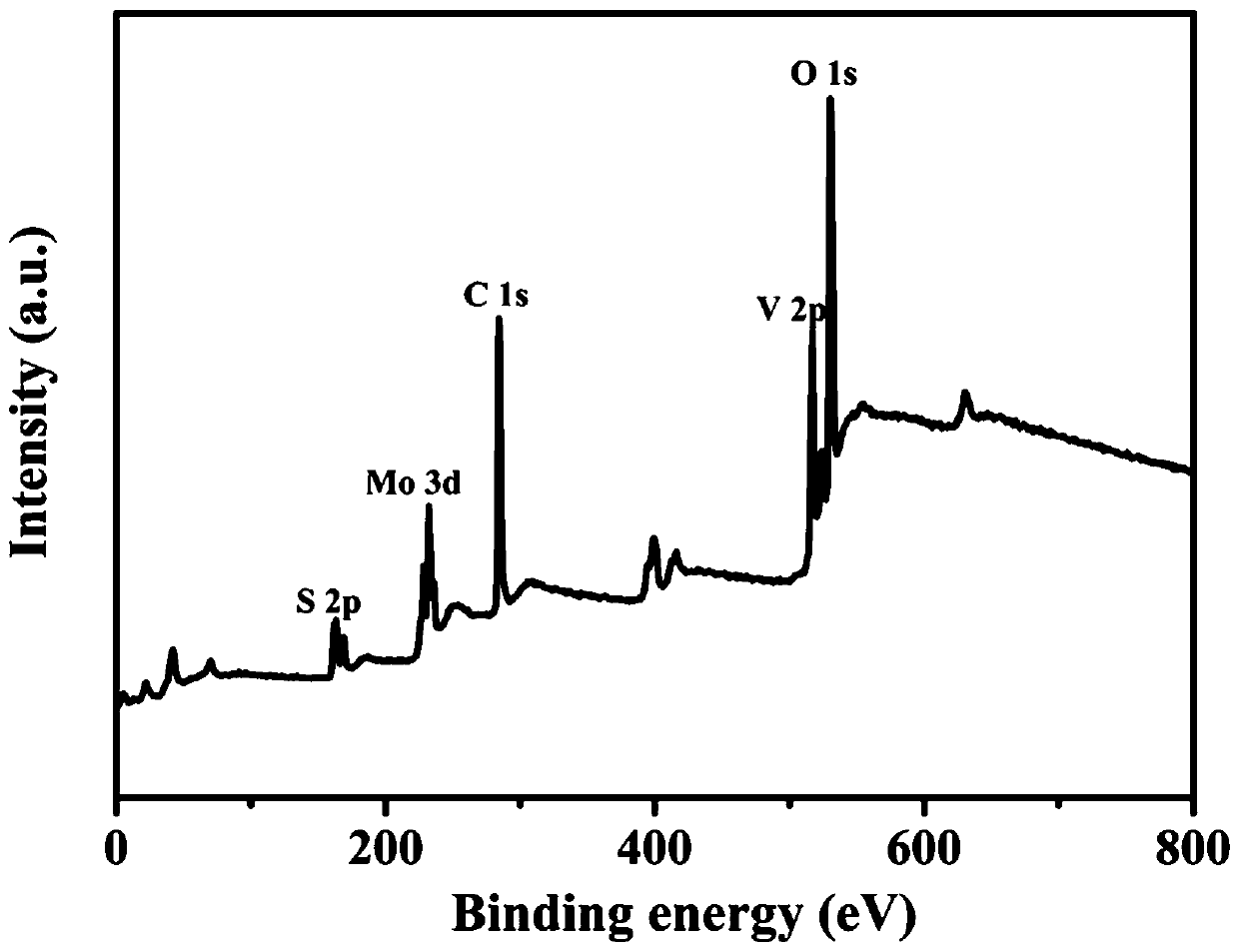

[0029] like Figure 1-Figure 6 Shown:

[0030] It is detected that the vanadium / molybdenum disulfide / carbon cloth material prepared in this embodiment is a metal phase.

[0031] It has been tested that the flaky vanadium / molybdenum disulfide material prepared in this embodiment grows ...

Embodiment 2

[0035] Add 50 mL of concentrated nitric acid into the inner lining of the reaction kettle, arrange the carbon in the inner lining of the reaction kettle, heat at 90°C for 8 h, wash and dry it for later use. Dissolve 80 mg of ammonium molybdate tetrahydrate, 1.4 g of L-cysteine, and 12 mg of sodium vanadate in 70 mL of deionized water. Pour the mixed solution into the lining of the reactor, add acid-treated carbon cloth material with a size of 3 cm*5 cm, and put it in an oven at 220 °C for 24 h. After naturally cooling to room temperature, the carbon cloth material was taken out, washed by centrifugation, and dried at 60°C to obtain a metal phase vanadium / molybdenum disulfide / carbon cloth material.

[0036] like Figure 7 It can be seen from the test that the vanadium / molybdenum disulfide / carbon cloth material prepared in this embodiment is a metal phase and the interlayer distance is relatively large.

[0037] After testing, in the vanadium / molybdenum disulfide / carbon cloth ...

Embodiment 3

[0041] Add 50 mL of concentrated nitric acid into the inner lining of the reaction kettle, arrange the carbon in the inner lining of the reaction kettle, heat at 90°C for 8 h, wash and dry it for later use. Dissolve 60 mg of ammonium molybdate tetrahydrate, 1 g of L-cysteine, and 18 mg of sodium vanadate in 70 mL of deionized water. Pour the mixed solution into the lining of the reactor, add acid-treated carbon cloth material with a size of 3 cm*5 cm, and place it in an oven at 220 °C for 24 h. After naturally cooling to room temperature, the carbon cloth composite material was taken out, washed by centrifugation, and dried at 60°C. A metallic phase vanadium / molybdenum disulfide / carbon cloth material is obtained.

[0042] like Figure 8 It can be seen from the test that the vanadium / molybdenum disulfide / carbon cloth material prepared in this embodiment is a metal phase and has a large interlayer distance.

[0043] It is tested that the flake-shaped vanadium / molybdenum disulfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com