Welding process of UNS N07208 superalloy pipe for boiler at 700 DEG C or above

A high-temperature alloy and welding process technology, applied in welding equipment, metal processing, welding accessories, etc., can solve the problems that the quality and joint performance cannot be guaranteed, the pass rate of welded joints is low, and welding research is relatively small. It can control welding defects, improve the pass rate of primary flaw detection, and ensure the effect of welding quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

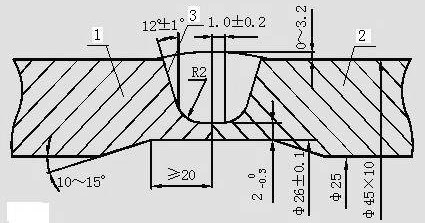

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0019] Take a project as an example, such as figure 1 As shown, a welding process of UNS N07208 high-temperature alloy pipes for boilers with a temperature exceeding 700 °C includes the following steps: A) Groove processing is performed on two UNS N07208 high-temperature alloy pipes 1 and 2 before welding. 3. Use stainless steel or nickel-based special grinding tools to polish and clean the area of not less than 20mm until it shows a metallic luster. If the ambient temperature is lower than 10°C, the welding area and the surrounding areas on both sides should not be less than 3 times the wall thickness and not less than 100mm Preheat to above 10°C; B) Assemble according to the requirements, pass pure argon shielding gas into the two superalloy tubes 1 and 2, adopt manual argon tungsten arc welding (GTAW), and the welding wire material is SFA-5.14 ERNiCrCoMo- 2 or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com