A kind of low-modulus solvent-free polyurethane resin for synthetic leather and preparation method thereof

A solvent-free polyurethane, low-modulus technology, applied in the field of polyurethane materials, can solve the problems of sealing agent and a small amount of solvent discharge, pollution of the environment, etc., and achieve the effects of improving melt fluidity, good soft hand, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A second aspect of the present invention provides the preparation method of the above-mentioned low modulus solvent-free polyurethane resin, comprising the steps of:

[0065] (1) Add polyether polyol, polyester polyol and additives into the reaction kettle according to the proportion, stir and mix at 50-60°C;

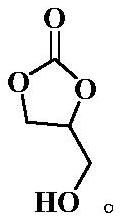

[0066] (2) Put the diisocyanate into the above-mentioned reaction kettle in batches, the reaction temperature is between 65-120°C, and after 2-8 hours of normal pressure reaction, when the NCO content is lower than the theoretical value, cool down to 60°C, drop Glycerol carbonate, after the dropwise addition, continues to react at 75-80°C until the NCO content in the system drops to zero, and the product is obtained after discharge.

[0067]The glycerol carbonate in the present invention adjusts the dropping rate according to specific circumstances, and can be slowly added dropwise in order to make the reaction stable. Measure the NCO content every half an hour ...

Embodiment 1

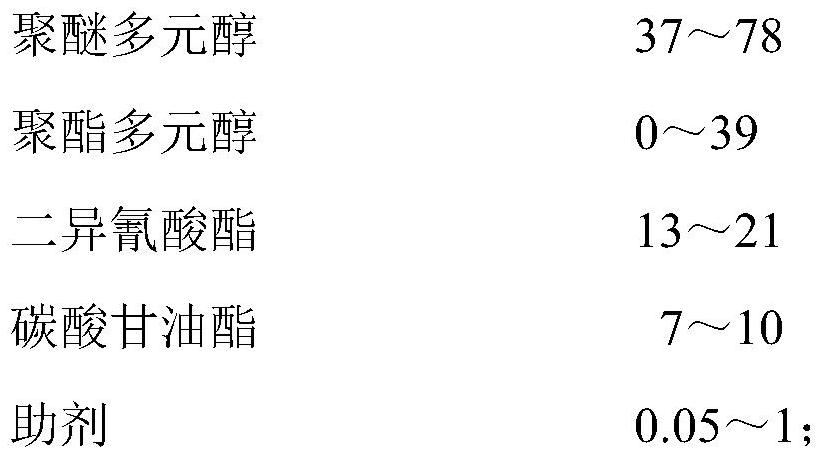

[0074] Example 1 : This embodiment provides a kind of low modulus solvent-free polyurethane resin, and its preparation raw material comprises (unit: gram):

[0075]

[0076] Wherein said diisocyanate is toluene diisocyanate; said polyether polyol is polyoxypropylene / oxyethylene copolytriol (number average molecular weight 3000).

[0077] The preparation method of above-mentioned low modulus solvent-free polyurethane resin comprises the steps:

[0078] (1) 750g polyoxypropylene / oxyethylene copolytriol and 0.5g antioxidant 1010 are put into the reactor, and stirred evenly at 50°C;

[0079] (2) Put 130.5g of toluene diisocyanate into the reaction kettle, strictly control the reaction temperature between 75-80°C, and after 5 hours of normal pressure reaction, take samples to measure the NCO content every half hour, and stop when the NCO content is lower than 3.5%. Heat, cool down to 60°C, slowly add 88.5g of glycerol carbonate dropwise, after the dropwise addition, continue t...

Embodiment 2

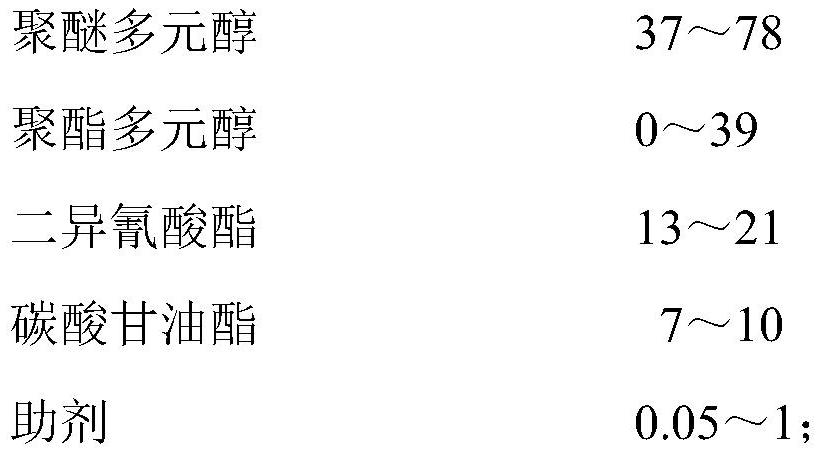

[0080] Example 2 : This embodiment provides a kind of low modulus solvent-free polyurethane resin, and its preparation raw material comprises (unit: gram):

[0081]

[0082] Wherein said diisocyanate is diphenylmethane 4,4-diisocyanate; Said polyether polyol consists of 450g polyoxypropylene / oxyethylene copolytriol (number average molecular weight 3000) and 225g polyoxyethylene diol (number average Molecular weight 2000) composition.

[0083] The preparation method of above-mentioned low modulus solvent-free polyurethane resin comprises the steps:

[0084] The preparation steps of the low modulus solvent-free polyurethane resin for synthetic leather of the present embodiment are as follows:

[0085] (1) Put 450g polyoxypropylene / oxyethylene copolytriol, 225g polyoxyethylene diol, 0.5g antioxidant 1010 into the reaction kettle, stir evenly at 50°C;

[0086] (2) Put 168.9g of diphenylmethane 4,4-diisocyanate into the reactor, strictly control the reaction temperature betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com