A kind of sponge for body armor and preparation method thereof

A technology of body armor and sponge, which is applied in the field of sponge, can solve the problems of large tensile strength depression and deformation, decreased flexibility of the wearer, and insufficient comfort for the wearer, and achieves high tensile strength and tear strength, fine pore size, slow rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

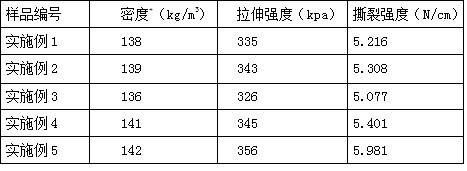

Examples

Embodiment 1

[0049] A sponge for bulletproof vests, comprising in parts by weight:

[0050] 25 parts of polyether polyol;

[0051] 25 parts of polymer polyol;

[0052] 40 parts of slow rebound polyether;

[0053] 17 TDIs;

[0054] 1.5 parts of amine catalyst;

[0055] 0.04 part of tin catalyst;

[0056] Tension agent 1.4 parts;

[0057] Toughening agent 0.7 part;

[0058] Silicone oil 0.6 part;

[0059] 0.5 part of water.

[0060] The hydroxyl value of the polyether polyol is 60 mgKOH / g and the molecular weight is 2500; the solid content of the polymer polyol is 43%; the hydroxyl value of the slow rebound polyether is 230 mgKOH / g and the molecular weight is 2300.

[0061] The preparation method of the sponge for bulletproof vests is as follows: mixing polyether polyol, polymer polyol, slow-rebound polyether, amine catalyst, tin catalyst, tensile agent, toughening agent, silicone oil, and water in proportion to 50,000 Stir for 10 to 20 s at a speed of rev / min, atomize and inject TD...

Embodiment 2

[0063] A sponge for bulletproof vests, comprising in parts by weight:

[0064] 40 parts of polyether polyol;

[0065] 15 parts of polymer polyol;

[0066] 50 parts of slow rebound polyether;

[0067] 23 TDIs;

[0068] 3 parts of amine catalyst;

[0069] Tin catalyst 0.07

[0070] Tension agent 1.8 parts;

[0071] Toughening agent 1.6 parts;

[0072] Silicone oil 0.8 part;

[0073] Water 0.6 parts.

[0074] The hydroxyl value of the polyether polyol is 55 mgKOH / g and the molecular weight is 2800; the solid content of the polymer polyol is 48%; the hydroxyl value of the slow rebound polyether is 230 mgKOH / g and the molecular weight is 1900.

[0075] The preparation method of Example 2 is the same as that of Example 1, and the specific steps are shown in Example 1, which will not be repeated here.

Embodiment 3

[0077] A sponge for bulletproof vests, comprising in parts by weight:

[0078] 25 parts of polyether polyol;

[0079] 15 parts of polymer polyol;

[0080] 40 parts of slow rebound polyether;

[0081] 15 TDIs;

[0082] 1.2 parts of amine catalyst;

[0083] Tin catalyst 0.03 part

[0084] Tension agent 1 part;

[0085] 1 part of toughening agent;

[0086] Silicone oil 0. part;

[0087] Water 0.4 parts.

[0088] The hydroxyl value of the polyether polyol is 50 mgKOH / g and the molecular weight is 3200; the solid content of the polymer polyol is 40%; the hydroxyl value of the slow rebound polyether is 240 mgKOH / g and the molecular weight is 2400.

[0089] The preparation method of Example 3 is the same as that of Example 1, and the specific steps are shown in Example 1, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com