ZIF-67/GO photocatalysis-photothermal composite film as well as preparation method and application thereof

A ZIF-67, composite film technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., to improve photocatalytic reduction activity and enhance light utilization. , the effect of promoting restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

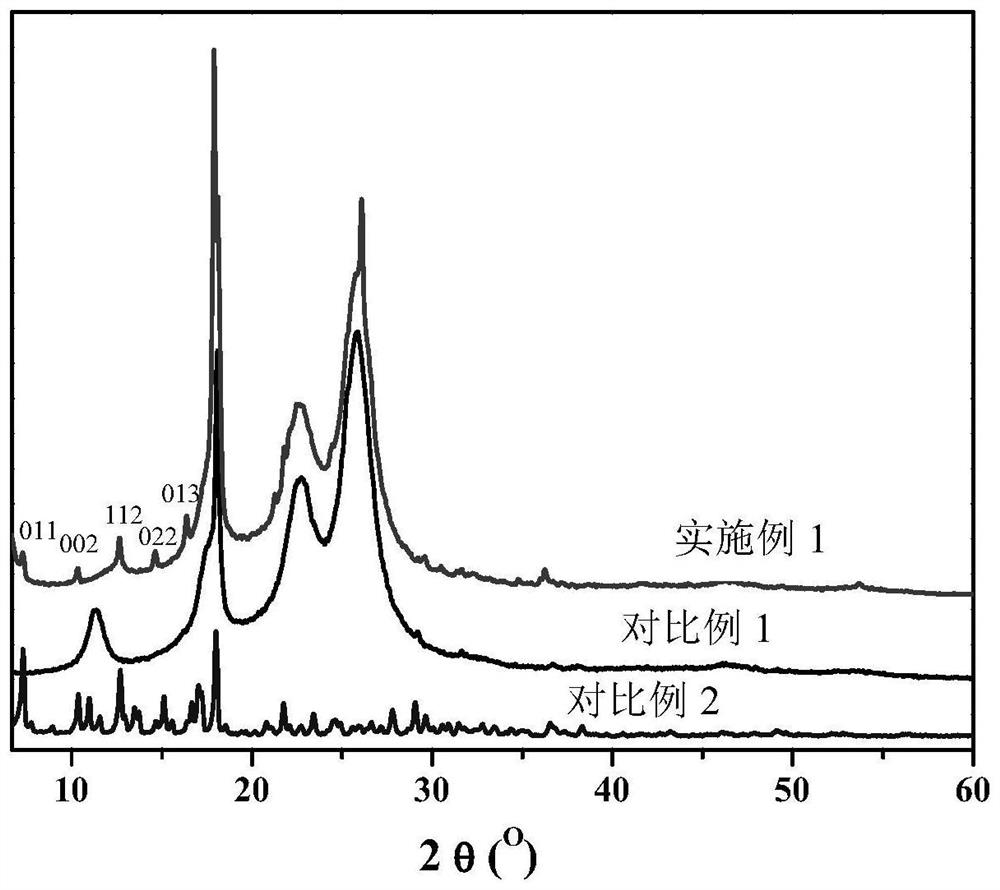

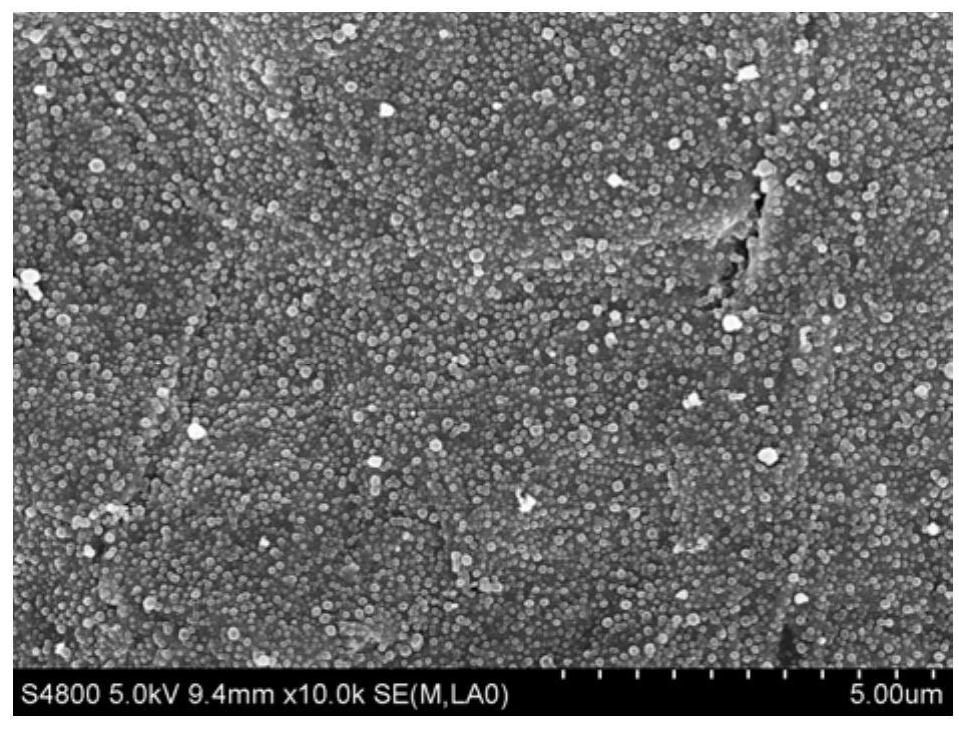

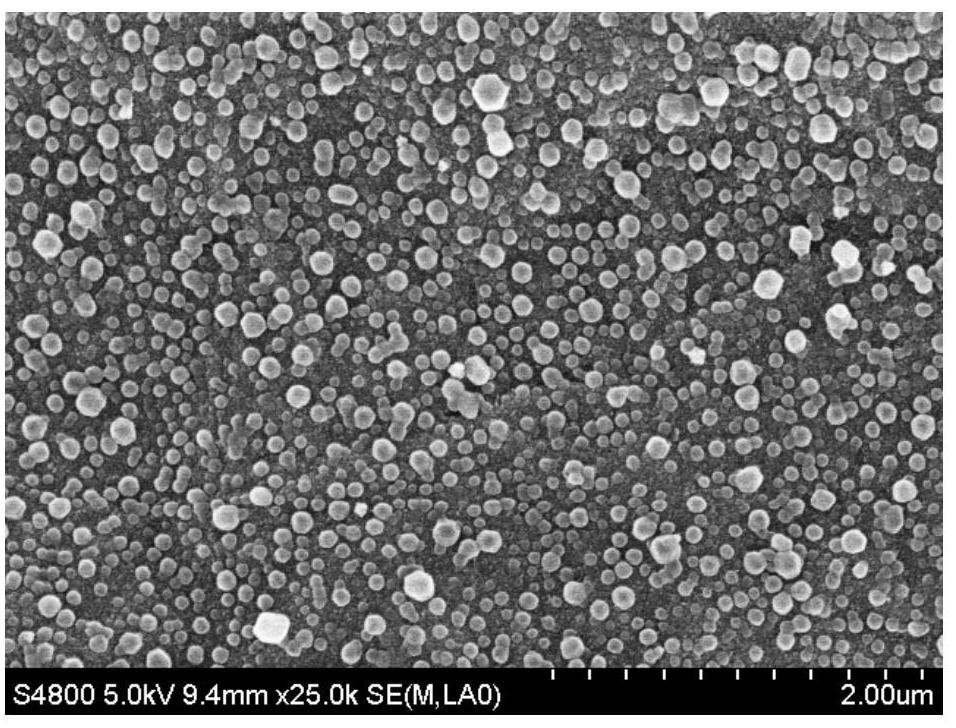

[0057] A ZIF-67 / GO photocatalytic-photothermal composite film can be prepared according to the preparation method of the above examples. In the ZIF-67 / GO photocatalytic-photothermal composite thin film, ZIF-67 crystals are evenly distributed on the surface of the GO film. The ZIF-67 / GO photocatalytic-photothermal composite thin film has photocatalytic activity in the visible light band of 420-780nm.

[0058] The ZIF-67 / GO photocatalytic-photothermal composite thin film can be used for photocatalytic-photothermal synergistic catalytic reduction of metal ions. Specifically, the ZIF-67 / GO photocatalytic-photothermal composite film has photocatalytic activity in the visible light band, and can be used as a photocatalyst for photocatalytic reduction of metal ions; at the same time, it has a photothermal effect, which can effectively concentrate the reactants and increase the water content. Pollutant removal efficiency in pollution treatment. Wherein, visible light is used in the ...

Embodiment 1

[0060] This embodiment provides a kind of ZIF-67 / GO photocatalytic-photothermal composite thin film, and its preparation method comprises the following steps:

[0061] a) 15mg of graphene oxide is added to 15mL of ultrapure water to obtain a homogeneous solution of graphene oxide, which is GO aqueous solution;

[0062] b) Suction filter the GO aqueous solution on the PTFE membrane, and dry it in the air at room temperature for 12 hours to prepare the GO membrane;

[0063] c) 100mL 5mol / L Co(NO 3 ) 2 ·6H 2 O methanol solution was poured into a petri dish equipped with GO film, and the solution was poured out after being kept at 40°C for 12 h, and the film was washed with methanol; then 100 mL of methanol solution of 2-methylimidazole (2-methylimidazole and The molar ratio of cobalt nitrate in water is 2:1) and poured into the container filled with Co(NO 3 ) 2 ·6H 2 In the petri dish of the GO film soaked in O solution, keep it at 40°C for 12h, pour off the solution, wash ...

Embodiment 2

[0081] The steps of this embodiment and embodiment 1 are basically the same, the difference is only: the Co(NO 3 ) 2 ·6H 2 O methanol solution was replaced by Co(NO 3 ) 2 ·6H 2 O in water, 2-methylimidazole in methanol was replaced by 2-methylimidazole in water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com