Method for efficiently recycling rare earth, fluorite and barite from rare earth tailings

A technology for rare earth tailings and barite, which is applied in the field of high-value mineral processing, energy saving and environmental protection, can solve the problems of low concentrate grade, high efficiency enrichment and recovery of rare earth, fluorite and barite, and high recovery costs, and achieves The effect of reducing processing scale and production cost, accurate and efficient selection, and strong suppression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

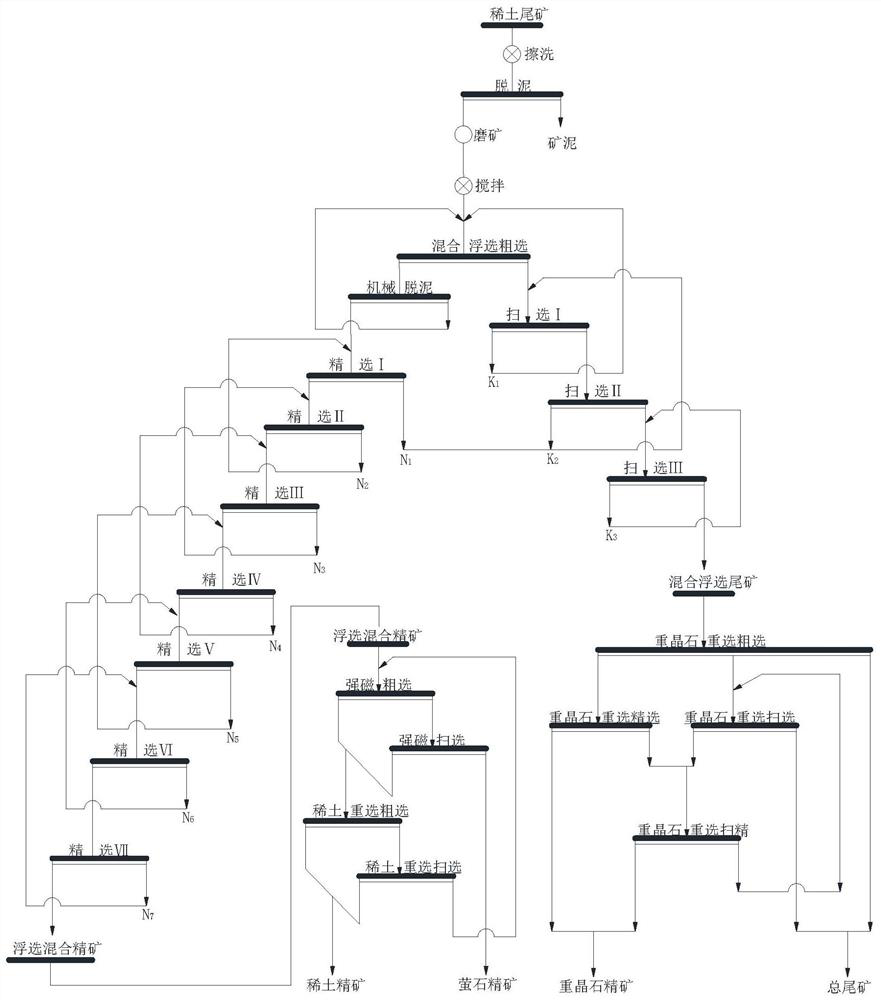

[0067] With TREO (total rare earth oxide) content as 0.7%, CaF 2 Content 25%, BaSO 4 The rare earth tailings with a content of 20% are used as raw materials, and the rare earth, fluorite and barite in the rare earth tailings are recovered. The process flow chart of the beneficiation process is as follows figure 1 As shown, the specific steps are as follows:

[0068] (1) Screening: use screening equipment to screen the rare earth tailings to remove foreign objects such as branches;

[0069] (2) scrubbing: the rare earth tailings under the sieve are added in the scrubbing equipment, the scrubbing concentration is controlled to 70%, the scrubbing time is 10min, and the scrubbing speed is 1000r / min;

[0070] (3) Desliming: use desliming equipment for desliming, and remove -0.038mm slime;

[0071] (4) Grinding: For rare earth tailings, use rod mill or ball mill for closed-circuit grinding operation, and add rare earth and fluorite collector 600g / t into the mill at the same time,...

Embodiment 2

[0094] With TREO (total rare earth oxide) content as 1.0%, CaF 2 Content 30%, BaSO 4 The rare earth tailings with a content of 35% are used as raw materials, and the rare earth, fluorite and barite in the rare earth tailings are recovered. The process flow chart of the beneficiation process is as follows figure 1 As shown, the specific steps are as follows:

[0095] (1) Screening: use screening equipment to screen the rare earth tailings to remove foreign objects such as branches;

[0096] (2) scrubbing: the rare earth tailings under the sieve are added in the scrubbing equipment, the scrubbing concentration is controlled to 70%, the scrubbing time is 10min, and the scrubbing speed is 1000r / min;

[0097] (3) Desliming: use desliming equipment for desliming, and remove -0.038mm slime;

[0098] (4) Grinding: For rare earth tailings, use rod mill or ball mill for closed-circuit grinding operation, and add rare earth and fluorite collector 600g / t into the mill at the same time,...

Embodiment 3

[0121] With TREO (total rare earth oxide) content as 0.5%, CaF 2 Content 18%, BaSO 4 The rare earth tailings with a content of 40% are used as raw materials, and the rare earth, fluorite and barite in the rare earth tailings are recovered. The process flow chart of the beneficiation process is as follows figure 1 As shown, the specific steps are as follows:

[0122] (1) Screening: use screening equipment to screen the rare earth tailings to remove foreign objects such as branches;

[0123] (2) scrubbing: the rare earth tailings under the sieve are added in the scrubbing equipment, the scrubbing concentration is controlled to 70%, the scrubbing time is 10min, and the scrubbing speed is 1000r / min;

[0124] (3) Desliming: use desliming equipment for desliming, and remove -0.038mm slime;

[0125] (4) Grinding: For rare earth tailings, use rod mill or ball mill for closed-circuit grinding operation, and add rare earth and fluorite collector 600g / t into the mill at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com