Film coating liquid for photovoltaic module, preparation method of film coating liquid and photovoltaic module

A photovoltaic module and coating solution technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of photovoltaic module safety accidents hindering the development of the photovoltaic industry, achieve excellent optical absorption performance, excellent waterproof performance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the purpose, features and advantages of the present invention more clearly, the implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The materials used, those whose manufacturers are not indicated, are conventional products that can be obtained through commercial purchase. The description of the exemplary embodiments is for the purpose of illustration only, and not limitation of the invention and its application.

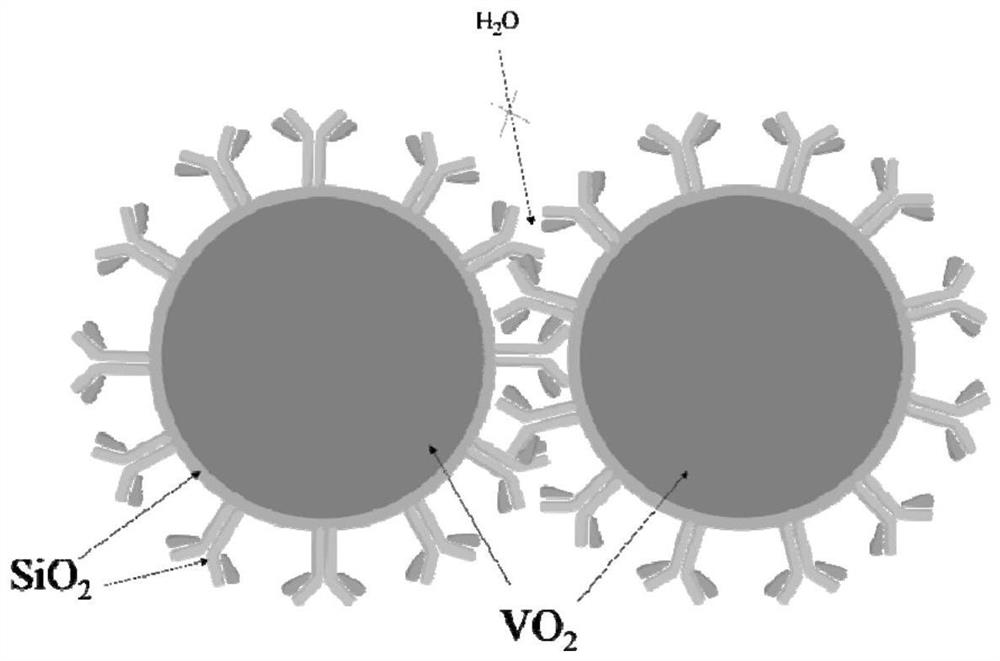

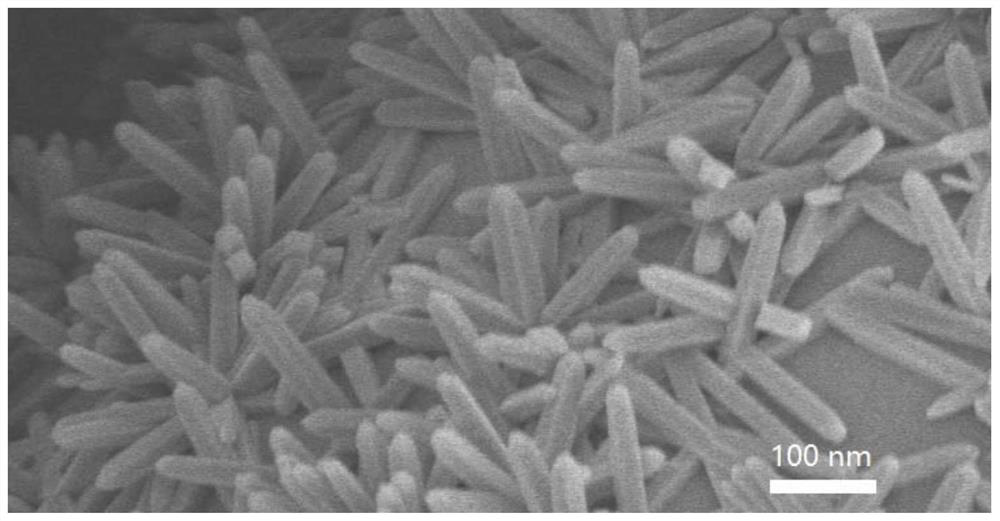

[0025] According to the first aspect of the present invention, some embodiments of the present invention provide a coating solution for photovoltaic modules, comprising an alcohol solvent and silica nanoparticles and vanadium dioxide@silicon dioxide nanoparticles dispersed in the alcohol solvent; two The vanadium oxide@silicon dioxide nanoparticles have a core-shell structure in which the core is covered with a shell, the core is vanadium dioxide, the shell is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com