Ultraviolet photodiode and preparation method thereof

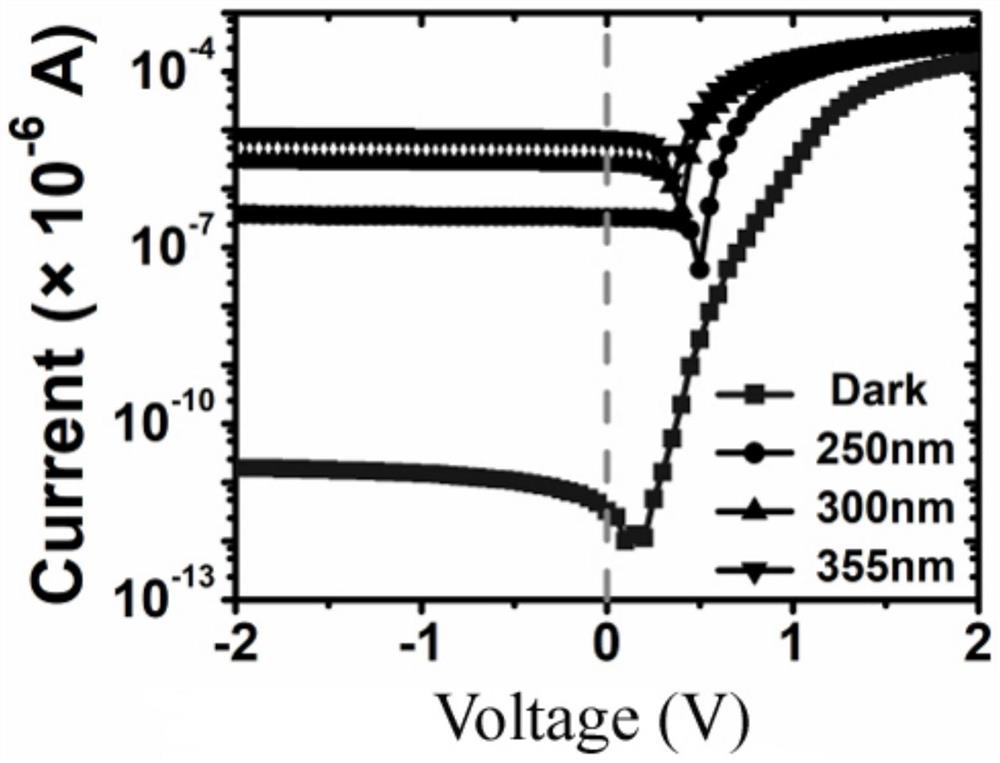

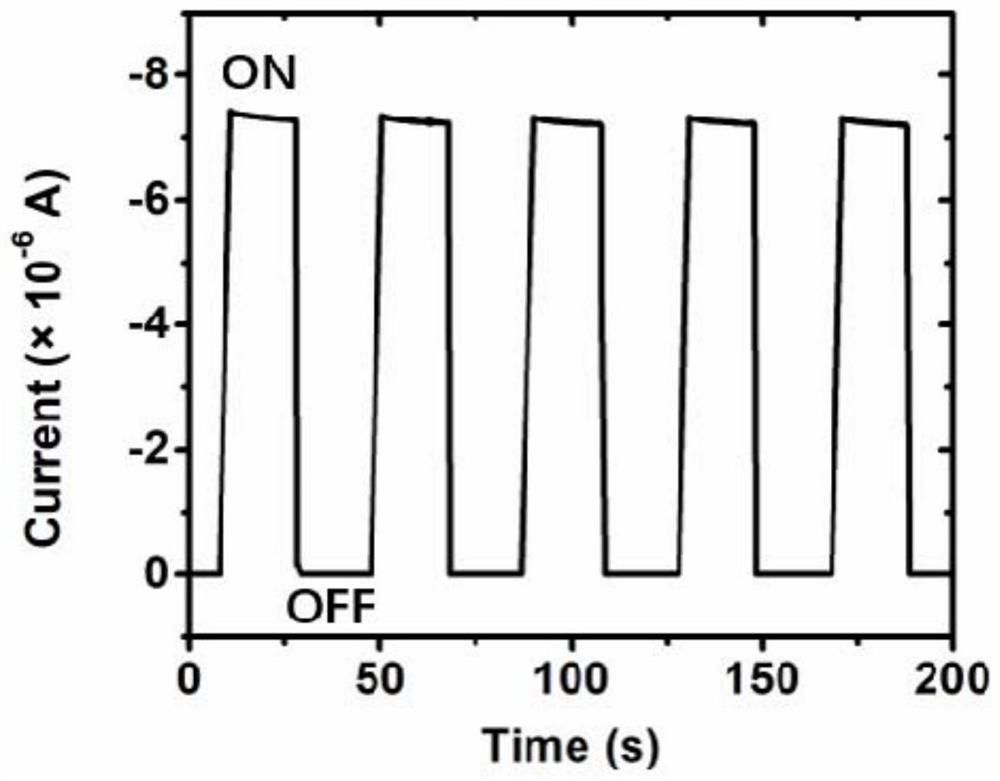

A technology of ultraviolet light and diodes, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low current on/off ratio, weak and low light absorption, small light response rate, etc., and achieve high responsivity rate and high light response rate, high-efficiency photoelectric conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

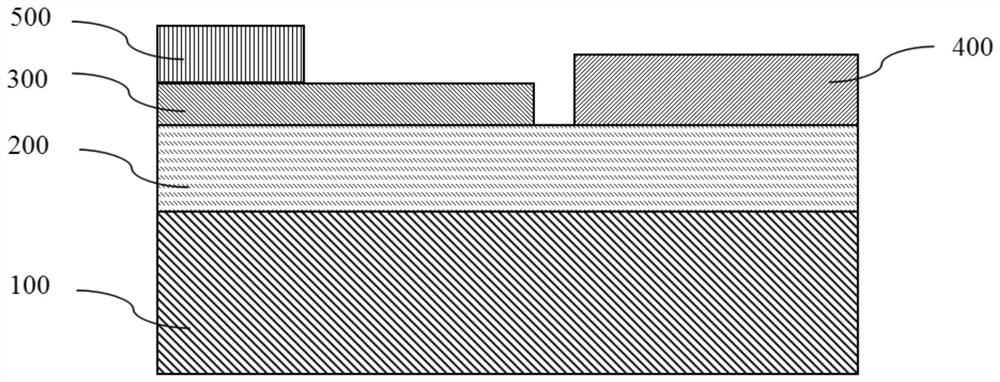

[0042] An ultraviolet photodiode comprising such as figure 1 The structure shown: substrate 100; GaN layer 200, disposed on the upper surface of the substrate 100; Ti 3 C 2 The Schottky contact layer 300 and the ohmic contact layer 400 are relatively arranged on both sides of the upper surface of the GaN layer 200; the metal contact layer 500 is arranged on the Ti 3 C 2 The upper surface of the Schottky contact layer 300 .

[0043] The preparation method of the ultraviolet photodiode is as follows:

[0044] (1) Put the no-clean sapphire substrate into the MOCVD (metal organic chemical vapor deposition) growth chamber, and use trimethylgallium, trimethylaluminum and NH on the sapphire substrate 3 As a source, nitrogen gas is used as a carrier gas, and a GaN nucleation layer of 50 nm, a GaN buffer layer of 200 nm, and an intrinsic GaN layer of 3 μm are epitaxy in sequence to form the GaN layer.

[0045] (2) at Ti 3 C 2 Add ice water to the colloid, centrifuge (3500rpm, 20...

Embodiment 2

[0048] A kind of ultraviolet photodiode, comprises following structure: substrate; GaN layer, is arranged on the upper surface of described substrate; Ti 3 C 2 The Schottky contact layer and the ohmic contact layer are relatively arranged on both sides of the upper surface of the GaN layer; the metal contact layer is arranged on the Ti 3 C 2 top surface of the Schottky contact layer.

[0049] The preparation method of the ultraviolet photodiode is as follows:

[0050] (1) Put the no-clean sapphire substrate into the MOCVD (metal organic chemical vapor deposition) growth chamber, and use trimethylgallium, trimethylaluminum and NH on the sapphire substrate 3 As a source, nitrogen gas is used as a carrier gas, and a GaN nucleation layer of 30 nm, a GaN buffer layer of 150 nm, and an intrinsic GaN layer of 5 μm are epitaxy in sequence to form the GaN layer.

[0051] (2) at Ti 3 C 2 Add ice water to the colloid, centrifuge (3500rpm, 20min), then take out the supernatant; repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com