Terahertz absorbing material with gradient aperture structure and preparation method thereof

A wave-absorbing material and terahertz technology, applied in the field of terahertz wave absorption, can solve problems such as the reduction of terahertz wave attenuation effect, the obstruction of terahertz wave incidence, and the reduction of absorption capacity, etc., and achieve strong broadband terahertz wave absorption characteristics, preparation Simple method, good bendable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

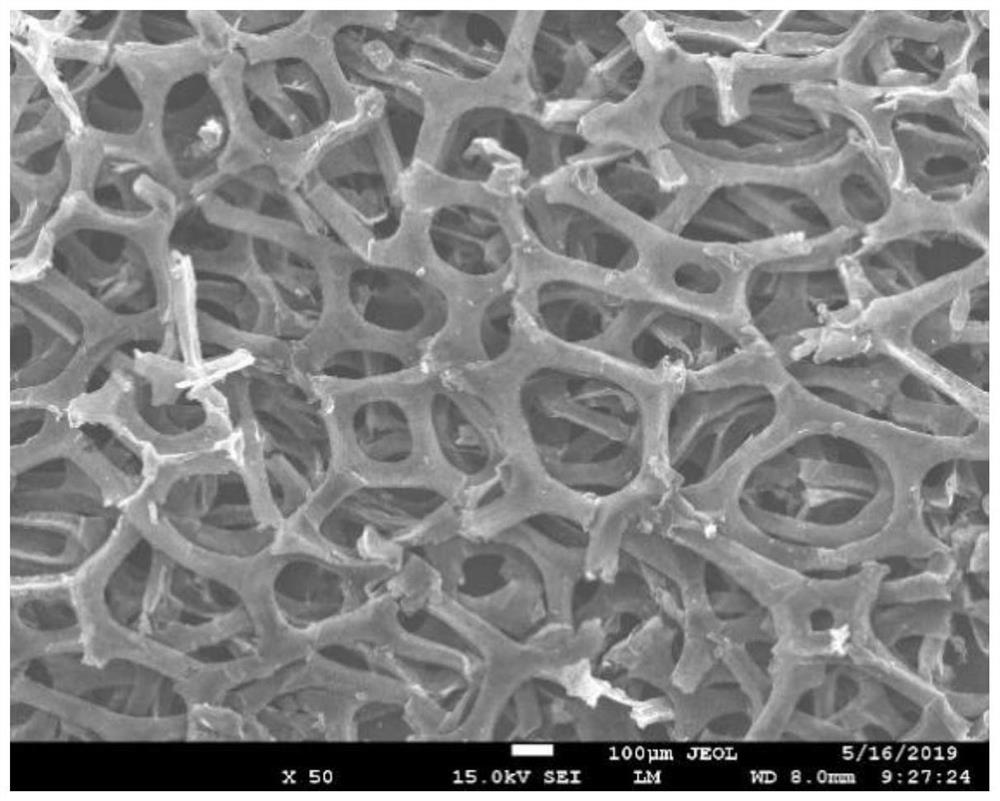

[0023] Step 1, preparing three-dimensional graphene with a nickel substrate and an average pore diameter of 110 μm. A template-guided chemical deposition method is used: nickel foam is used as the deposition substrate, methane is used as the growth carbon source, and a 100mm caliber quartz tube furnace is used as the growth equipment; nickel foam with an average pore size of 110 μm is placed in the tube furnace, and 10 sccm methane is introduced As the growth gas, the growth time is 30min; after completion, the methane gas is turned off, and the temperature is naturally lowered to room temperature.

[0024] Step 2, preparing three-dimensional graphene. Get concentration is 2mol / L hydrogen chloride (HCL) solution 10ml, concentration is 2mol / L iron trichloride (FeCl 3 ) solution 10ml, hydrogen chloride solution and ferric chloride solution are mixed to obtain a mixed solution; the three-dimensional graphene with a nickel substrate obtained in step 1 is put into the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com