Aspergillus oryzae and applications of aspergillus oryzae in brewing soy sauce

A technology of Aspergillus oryzae and soy sauce, which is applied in the field of microbial fermentation, can solve problems such as precipitation that affects pressing efficiency and product appearance, and achieves the effects of reducing insoluble acidic polysaccharides, enhancing the flavor of soy sauce, and reducing precipitation of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

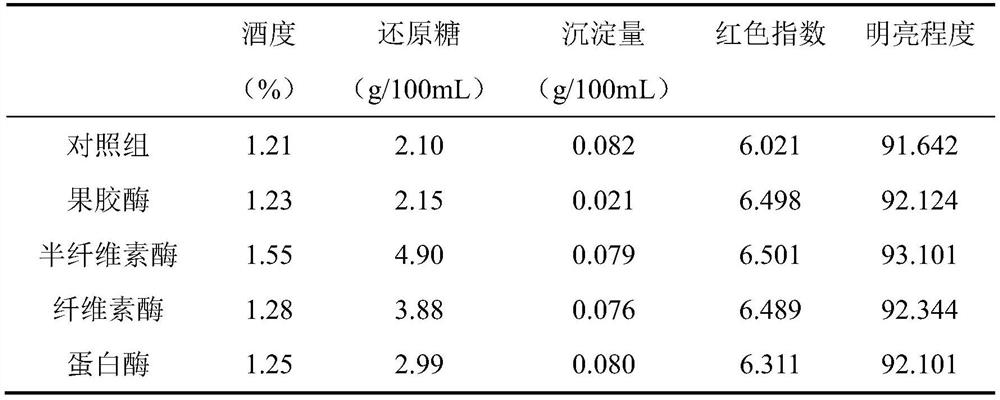

[0019] Effects of Exogenous Enzymes on Precipitation and Flavor of Soy Sauce

[0020] Wheat flour, soybean meal, and water were mixed in proportion, sterilized at 121°C for 30 minutes, cooled to below 40°C, and Aspergillus oryzae As 3.042 was inserted into the material with an inoculation amount of 4‰, and cultured for 40 minutes at a temperature of 30°C and a humidity of 95%. ~ 60h, made into song. According to the ratio of 1:1.8, add brine with a salt concentration of 22-23% to the finished koji and transfer it to the fermentation tank. 8 ~10 9 CFU / mL bacterial concentration was added with Zygomyces rouckeri, and 0.1‰ exogenous enzymes were added at the same time, kept at 30°C for 6 months to obtain finished soy sauce, and the physical and chemical indicators, precipitation and flavor substances of soy sauce were detected. No exogenous enzymes were added to the control group, and the exogenous enzymes added to the other groups were pectinase, hemicellulase, cellulase, and ...

Embodiment 2

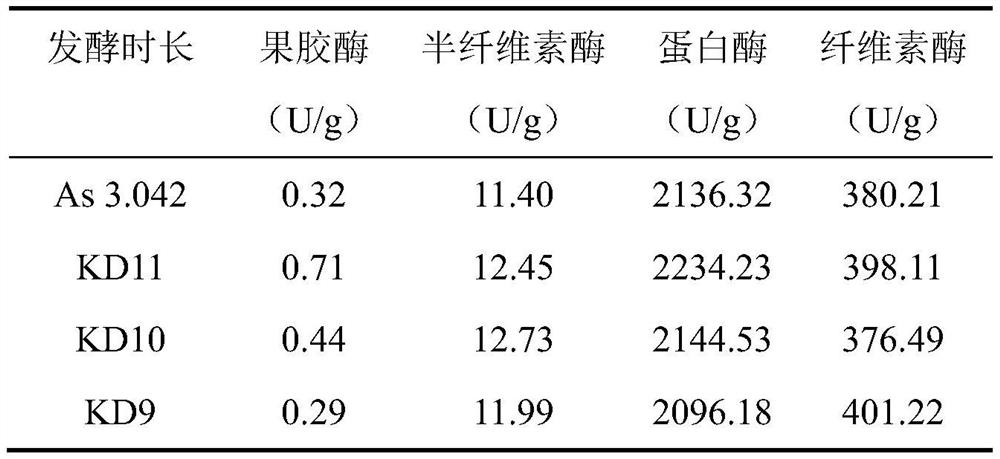

[0025] Aspergillus activity of different Aspergillus oryzae

[0026] Aspergillus oryzae As 3.042 was used as the starting strain for ARTP mutagenesis. ARTP mutagenesis conditions were as follows: 10 μL of Aspergillus oryzae suspension was placed in a fixed position of the ARTP mutagenesis instrument, the air flow was 9.5-10 SLM, and the mutagenesis treatment time was 165-175 s. Mutants were obtained, and several strains of high quality were selected from the mutants. Excellent Aspergillus oryzae mutant strains KD11, KD10, KD9. The difference between the three mutant strains KD11, KD10, and KD9 is that when making koji, KD11 has a higher pectinase activity while KD10 has a higher Hemicellulase activity, KD9 has higher cellulase activity.

[0027] Wheat flour, soybean meal, and water are mixed in proportion, then sterilized at 121°C for 30 minutes, cooled to below 40°C, and the Aspergillus oryzae strain is inserted into the material with an inoculum amount of 4‰, and cultured ...

Embodiment 3

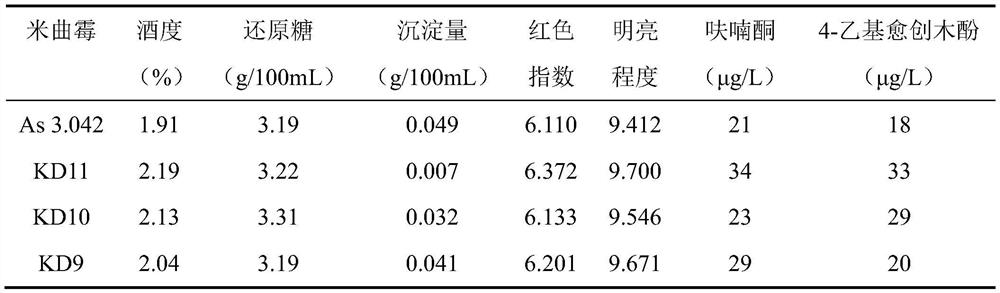

[0031] Effects of different Aspergillus oryzae koji making on the precipitation and flavor of soy sauce with different fermentation time

[0032] Wheat flour, soybean meal, and water are mixed in proportion, then sterilized at 121°C for 30 minutes, cooled to below 40°C, and the Aspergillus oryzae strain is inserted into the material with an inoculum amount of 4‰, and cultured at a temperature of 30°C and a humidity of 95% for 40~ After 60 hours, a koji was prepared. According to the ratio of 1:1.8, add brine with a salt concentration of 22-23% to the finished koji and transfer it to the fermentation tank. 8 ~10 9 CFU / mL bacterial concentration Add Zygomyces luschii, keep it fermented at 30°C for 3-6 months to obtain finished soy sauce, and detect soy sauce precipitation and flavor substances. The results are shown in Table 3-5.

[0033] Table 3 Effects of different Aspergillus oryzae koji production on finished soy sauce fermented for 6 months

[0034]

[0035] Table 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com