Fermentation process of zero-additive soy sauce easy to squeeze and high in red and bright index

A fermentation process and zero-addition technology, applied in the field of microbial fermentation, can solve the problems of low amino acid nitrogen in soy sauce, high difficulty in pressing and filtering, and aggravated precipitation, so as to reduce insoluble acidic polysaccharides, improve raw material utilization, and increase the proportion than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

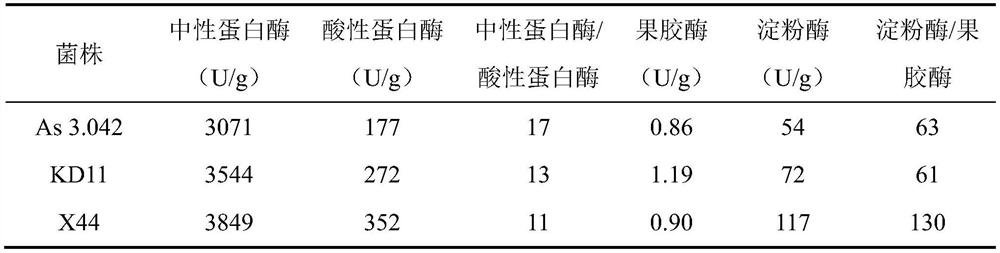

[0024] Comparing the Aspergillus activity of different single Aspergillus oryzae

[0025] Wheat flour, soybean meal, and water are mixed in proportion, sterilized at 121°C for 30 minutes, cooled to below 40°C, and the Aspergillus oryzae origin strain As 3.042, KD11 strain, and X44 strain are respectively inserted into the material with an inoculation amount of 4‰, and the temperature is controlled at 30°C 1. Cultivate for 40-60 hours under the condition of 95% humidity to prepare koji. Detect the enzyme activity related to song formation (enzyme activity is calculated on a dry basis). The results are shown in Table 1.

[0026] Table 1 Comparison of Aspergillus oryzae enzyme activity produced by different Aspergillus oryzae mutant strains with that of the original strain

[0027]

[0028] As can be seen from the results in Table 1, the enzyme activities of the Aspergillus oryzae mutant strains were higher than those of the starting strain As 3.042, but the enzyme activity ...

Embodiment 2

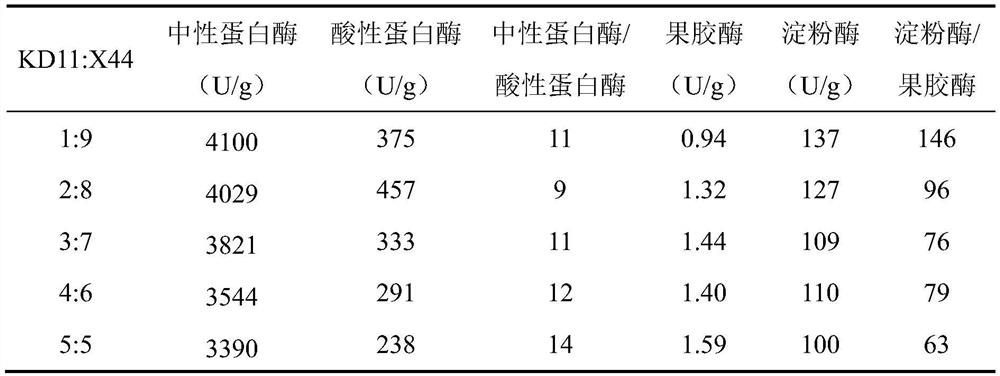

[0030] Comparing the activity of Aspergillus oryzae prepared by aspergillus oryzae with different compound ratio

[0031] Mix bran, soybean meal, and water amine 3:7:7, sterilize, cool, inoculate the material with strains KD11 and X44, and cultivate to obtain koji. Mix wheat flour, soybean meal, and water according to the ratio of 3:7:7, sterilize, cool, mix the koji prepared by strain KD11 and strain X44 into the material in proportion, and cultivate under the conditions of controlling temperature at 30°C and humidity at 95%. 40 ~ 60h, made into song. Detect the enzyme activity related to song making (enzyme activity is calculated on a dry basis), and the results are shown in Table 2.

[0032] Aspergillus activity produced by compound strains in table 2

[0033]

[0034] From the results in Table 2, it can be seen that the enzyme activity ratio of protease / acid protease after the compounding of strain KD11 and X44 can reach 8-10, and the enzyme activity ratio of amylase / ...

Embodiment 3

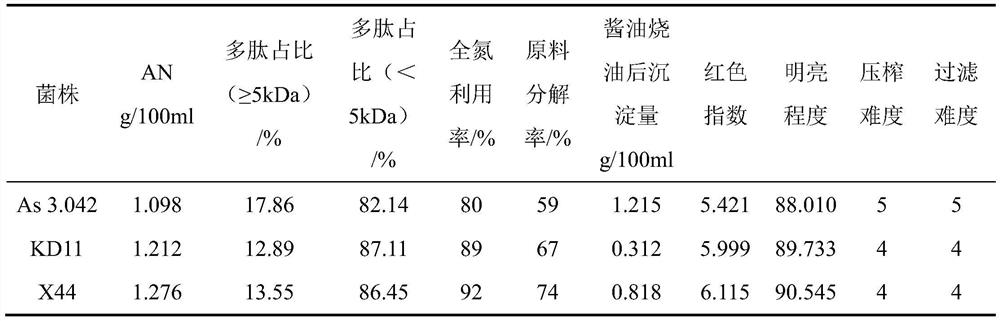

[0037] Comparing the quality of zero additive soy sauce produced by fermentation of single Aspergillus oryzae

[0038] Wheat flour, soybean meal, and water are mixed in proportion, sterilized at 121°C for 30 minutes, cooled to below 40°C, and Aspergillus oryzae origin strain As 3.042, KD11 strain, and X44 strain are inserted into the material at an inoculation amount of 4‰, and the temperature is controlled at 30°C, The humidity is 95% and cultivated for 40-60 hours to prepare koji. Add salt water with a salt concentration of 22-23% to the koji at a ratio of 1:1.8-2.5, put the koji mixed with salt water into a fermentation tank, ferment for 3-6 months, and sterilize to obtain finished soy sauce. The test results of soy sauce are shown in Table 3.

[0039] Table 3 Detection of related indicators of zero-added soy sauce in koji fermentation of different Aspergillus oryzae mutant strains

[0040]

[0041] Note: Squeeze difficulty and filter difficulty are graded according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com