Green roof structure and construction method thereof

A construction method and roof structure layer technology, applied in the direction of roof, roof covering layer, building structure, etc., can solve the problems of low application range and single function of green roof, and achieve wide application range, obvious energy saving and environmental protection effect, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

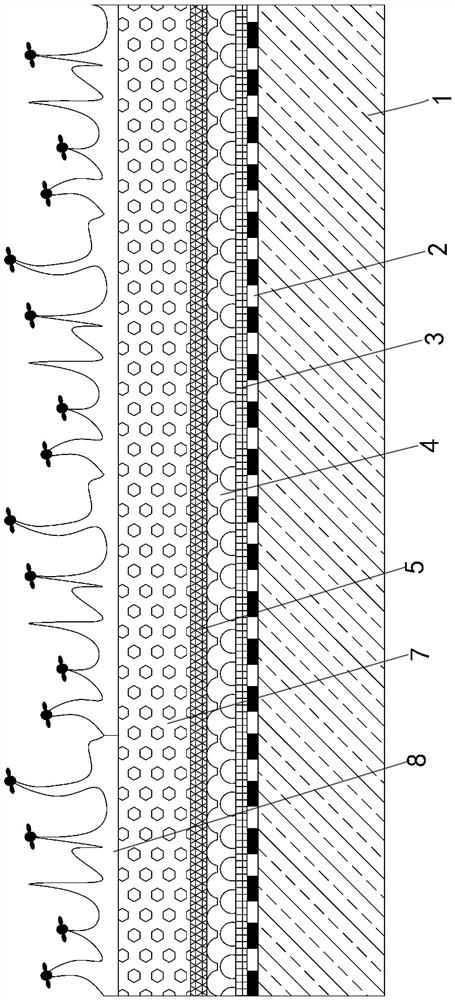

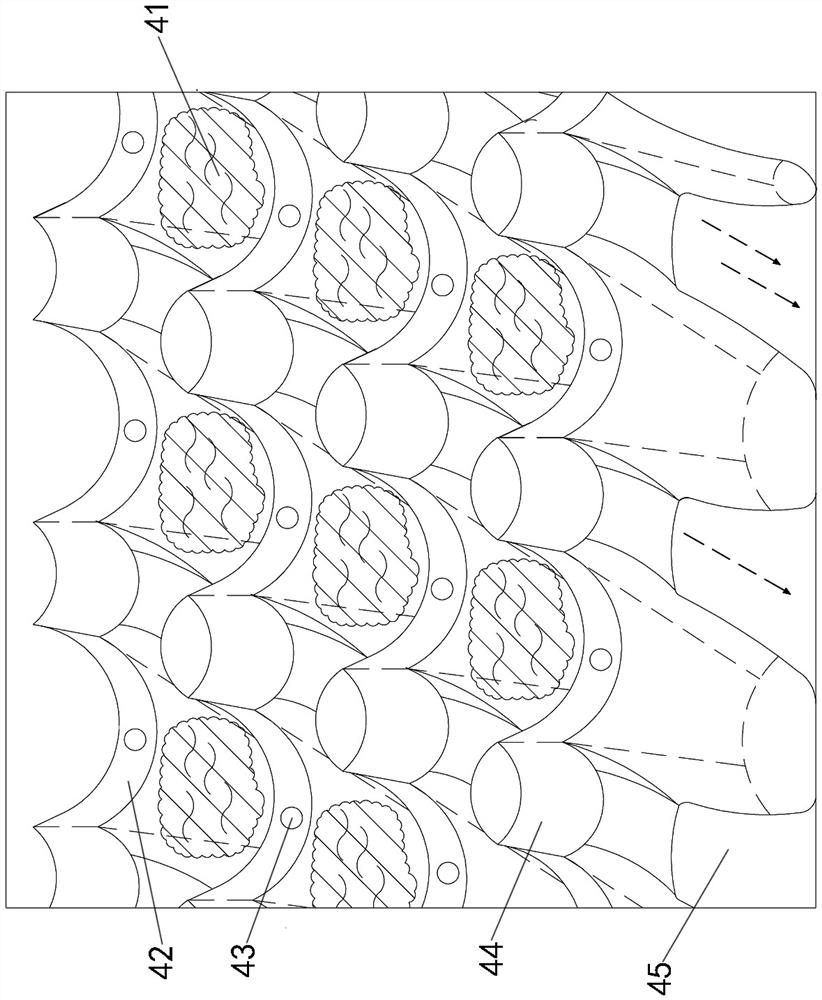

[0084] Embodiment one sees Figure 1-3 As shown, a green roof structure includes a roof structure layer 1, and also includes a waterproof insulation layer 2, a protective isolation layer 3, and a solid The aquifer 4, the soil layer 5, the soil barrier 6, the soil layer 7 and the plant layer 8.

[0085] The waterproof and thermal insulation layer 2 is a waterproof thermal insulation layer of acrylic acid recycling fibers resistant to root puncture.

[0086] The protective isolation layer 3 is laid on the upper side of the waterproof insulation layer 2 in the same laying direction as the waterproof insulation layer 2, and the junction with the facade wall is turned up 100mm, and the vertical and horizontal overlap width is 100mm. When encountering pipes and tube wells protruding from the roof, turn up 100mm. The protective isolation layer 3 is an acrylic recycled fiber layer. Material grade 2, material thickness about 3mm, weight about 300g per square meter, resist mechanical...

Embodiment 2

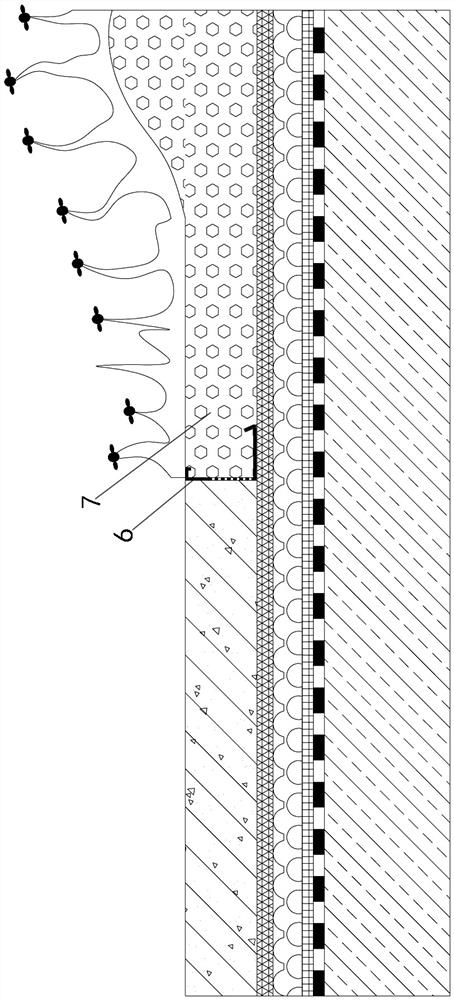

[0096] Embodiment two see Figure 4 As shown, a green roof structure is different from the first embodiment in that it also includes the upper side of the roof structure layer 1 and the sidewalk area between the soil barriers 6 in the planting areas on both sides.

[0097] The sidewalk area includes a waterproof insulation layer 2, a protective isolation layer 3, a double-layer PE film sliding layer 9, a drainage board 10, a crushed stone mixture layer 11 and a road slab layer that are sequentially compounded on the upper surface of the roof structure layer 1 from bottom to top. 12.

[0098] The double-layer PE film sliding layer 9 is laid on the upper side of the protective isolation layer 3, and both ends extend toward the planting area.

[0099]The drainage board 10 is laid on the upper side of the double-layer PE film sliding layer 9, the drainage board is FKD 10, made of high-density polyethylene recycled material, and the polypropylene PP filter layer is about 10mm thic...

Embodiment 3

[0102] Embodiment three see Figure 5 As shown, a green roof structure is different from the second embodiment in that the sidewalk area is also provided with a floor drain area, and the roof structure layer 1 of the floor drain area forms a floor drain that is disconnected from small to large steps from bottom to top. Space 13, the four sides of the floor drain space are provided with a transition layer 14 adapted to and connected to the shape of the roof structure layer 1, and the middle part of the floor drain space penetrates up and down.

[0103] The upper surface of the edge of the transition layer 14 is flush with the upper surface of the roof structure layer 1, the upper surface of the transition layer 14 gradually slopes downward from the edge to the center, and the upper surface of the transition layer 14 is It is connected with a waterproof insulation layer 2, a protective isolation layer 3, a double-layer PE film sliding layer 9 and a drainage board 10, which exten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com