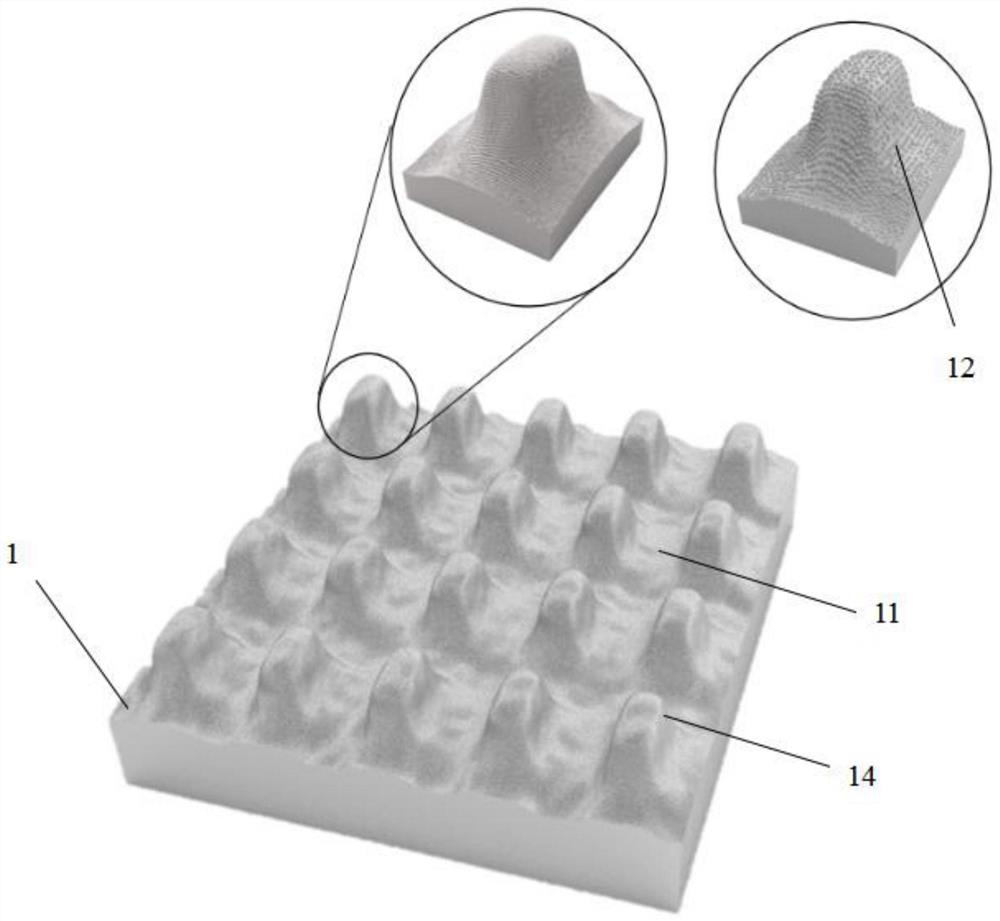

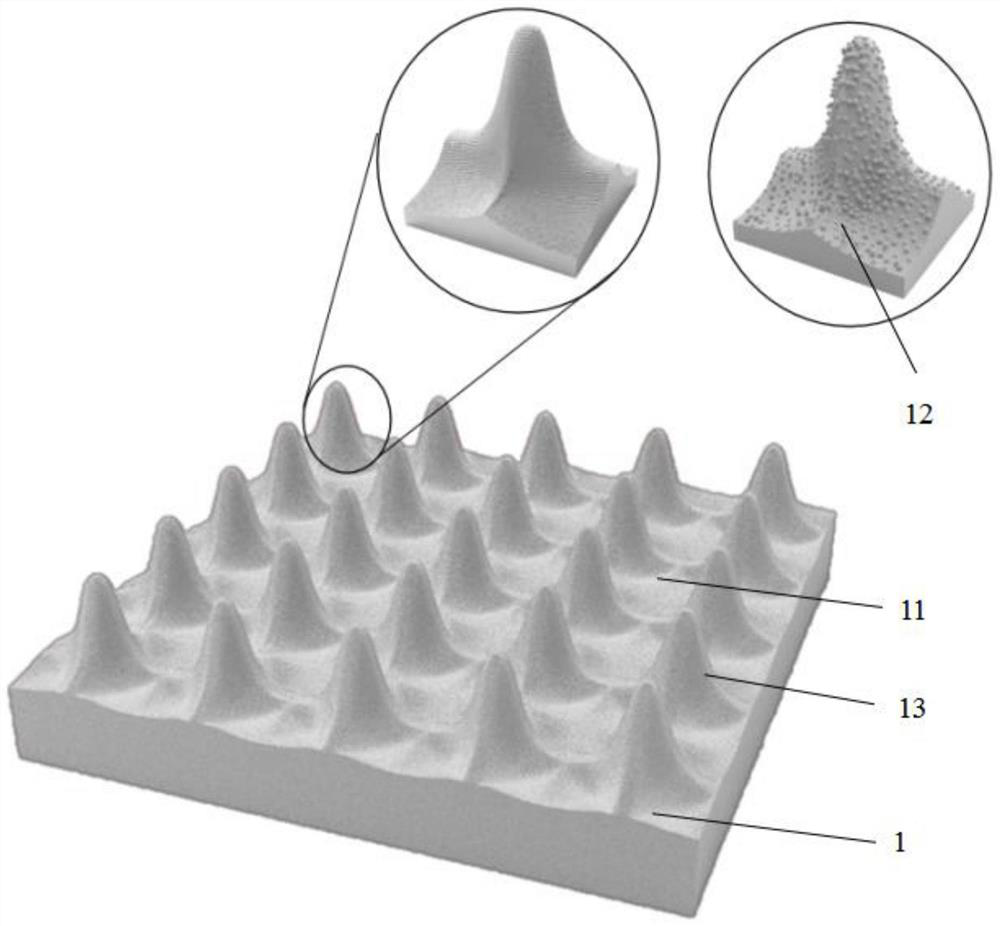

Ultrathin soaking plate super-hydrophilic micro-nano-structure liquid absorbing core and preparation method

A technology of micro-nano structure and liquid-absorbing core, which is applied in the field of heat pipes, can solve the problems of reduced heat transfer efficiency, difficulty in further reducing thickness, and decreased capillary performance, so as to reduce water resistance and air resistance, avoid collapse, and improve overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the ultra-hydrophilic micro-nano structure liquid-absorbing core of the ultra-thin copper alloy vapor chamber comprises the following steps:

[0045] (1) The cover plate or the lower cover plate on the copper alloy soaking plate is used for pre-treatment such as cutting and cleaning. The thickness of the copper alloy cover plate can be 0.2-1 mm, and 0.4 mm is selected;

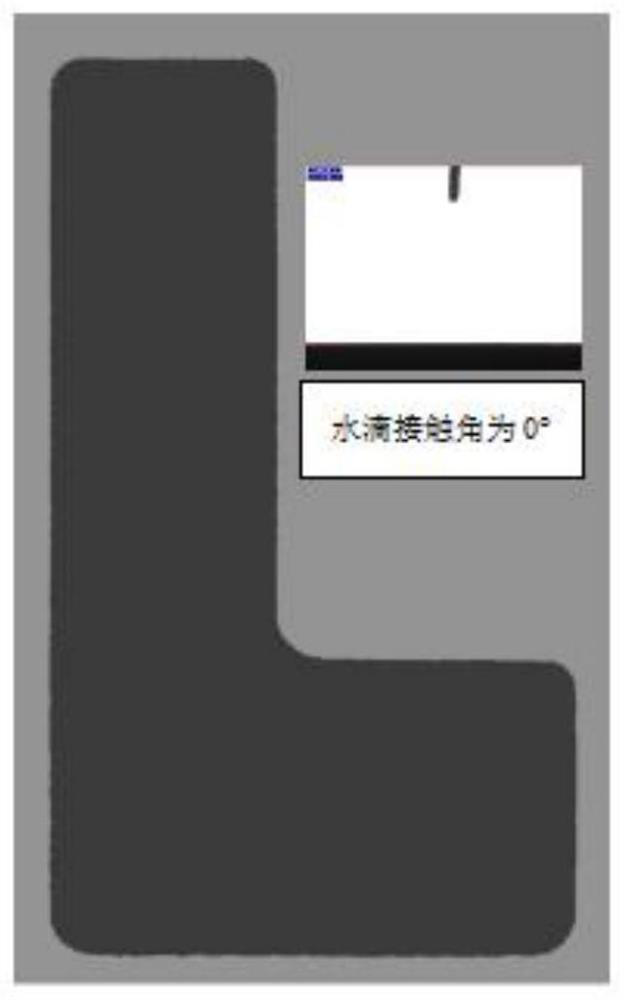

[0046] (2) The liquid-absorbing core is directly prepared on the copper alloy soaking plate cover plate. According to the shape requirements of the soaking plate for the liquid-absorbing core area, the scanning area of the ultra-fast laser is square, rectangular, cross-shaped, T-shaped, and L-shaped. Shape, I-shape, triangle, bar shape, circle, radial shape and various shapes such as combinations thereof, L-shape is selected in this embodiment, and micro-nano structures are prepared in the above-mentioned shape area;

[0047] (3) Using picosecond laser, the wavelength is near...

Embodiment 2

[0052] The preparation method of the super-hydrophilic micro-nano structure liquid-absorbing core of the ultra-thin aluminum alloy soaking plate comprises the following steps:

[0053] (1) The aluminum alloy soaking plate cover plate is used for pretreatment such as cutting and cleaning, the thickness of the aluminum alloy cover plate can be 0.2-1mm, and 0.3mm is selected;

[0054] (2) The liquid-absorbing core is directly prepared on the vapor chamber cover plate. According to the shape requirements of the vapor chamber for the liquid-absorbing core area, the scanning area of the ultra-fast laser is prepared as a square, rectangle, cross, T-shape, L-shape, Various shapes such as I-shape, triangle, strip, circle, radial shape and combinations thereof, T-shape is selected in this embodiment, and micro-nano structures are prepared in the above-mentioned shape area;

[0055] (3) Using femtosecond laser, the wavelength is green light, the pulse width of femtosecond laser is 10-1...

Embodiment 3

[0060] The preparation method of the super-hydrophilic micro-nano structure liquid-absorbing core of the stainless steel soaking plate comprises the following steps:

[0061](1) The cover plate or the lower cover plate on the stainless steel soaking plate is used for pre-treatment such as cutting and cleaning. The thickness of the stainless steel cover plate can be 0.2-1 mm, and 0.2 mm is selected;

[0062] (2) The liquid-absorbing core is directly prepared on the vapor chamber cover plate. According to the shape requirements of the vapor chamber for the liquid-absorbing core area, the scanning area of the ultra-fast laser is prepared as a square, rectangle, cross, T-shape, L-shape, Various shapes such as I-shaped, triangle, strip, circular, radial and combinations thereof, the present embodiment chooses I-shaped, and prepares micro-nano structures in the above-mentioned shape area;

[0063] (3) Using picosecond laser, the wavelength is near infrared, the pulse width of pico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com