Three-dimensional cluster type aircraft panel automatic assembly production line and its planning control method

A technology for assembling production lines and aircraft panels. It is used in data processing applications, instruments, geometric CAD, etc., and can solve problems such as large floor space, affecting hole-making accuracy and assembly efficiency, and single station.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

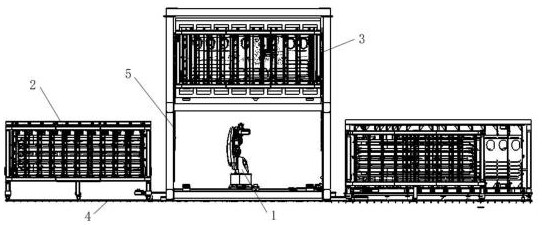

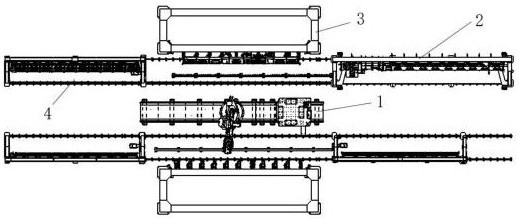

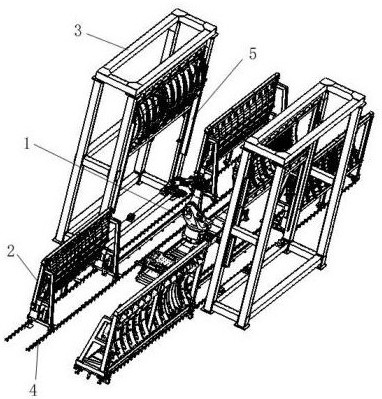

[0064] See Figure 1 to Figure 9 , the present invention has a hole-making system and a frame tooling 2 for positioning wall panels; the hole-making system 1 is a robot hole-making system; it also has a double-layer three-dimensional platform; the hole-making system 1 is fixed on the lower floor of the double-layer three-dimensional platform On the ground; two left and right translation modules 4 are arranged in parallel on the ground where the lower layer of the double-layer three-dimensional platform is located, and the two left and right translation modules 4 are located on the front and rear sides of the hole making system 1; each left and right translation module 4 There are three mobile stations, left, middle and right, and two frame tooling 2 that match the mobile stations and are slidably arranged on the left and right translation modules 4, corresponding to the front side and the middle mobile station of the left and right translation modules 4 in front. The rear posi...

Embodiment 2)

[0077] This embodiment is basically the same as Embodiment 4, and its distinguishing feature is that it consists of two sets of independent three-dimensional cluster automatic assembly production lines. Such as Figure 4 to Figure 9 As shown, the three-dimensional platforms of the two production lines are connected together and share a large platform.

Embodiment 3)

[0079] See Figure 10 to Figure 15 , a planning control method for a three-dimensional clustered aircraft panel automatic assembly production line. First, according to the actual production process of the aircraft, the panel assembly process flow is decomposed and the operation sequence is planned to form a preliminary panel assembly process sequence diagram, which is used as basis for further work. Among them, the wallboard assembly process is roughly decomposed into five parts: pre-positioning of wallboard components, automatic hole making, riveting of the main structure, riveting of system components, and quality inspection delivery. Preliminary assembly process timing flow chart. Then, on the basis of the above sequence flow chart, analyze the time, space and resource consumption of the operation process, clarify the various requirements for the construction of the cluster panel assembly production line, and further improve and optimize the assembly process. During this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com