Narrow-linewidth tunable laser device and preparation method thereof

A laser and narrow linewidth technology, applied in the field of lasers, can solve the problems of chip yield drop, affect chip end surface coating and mounting process, and reliability drop, so as to improve stability, reduce beam divergence angle, and reduce size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

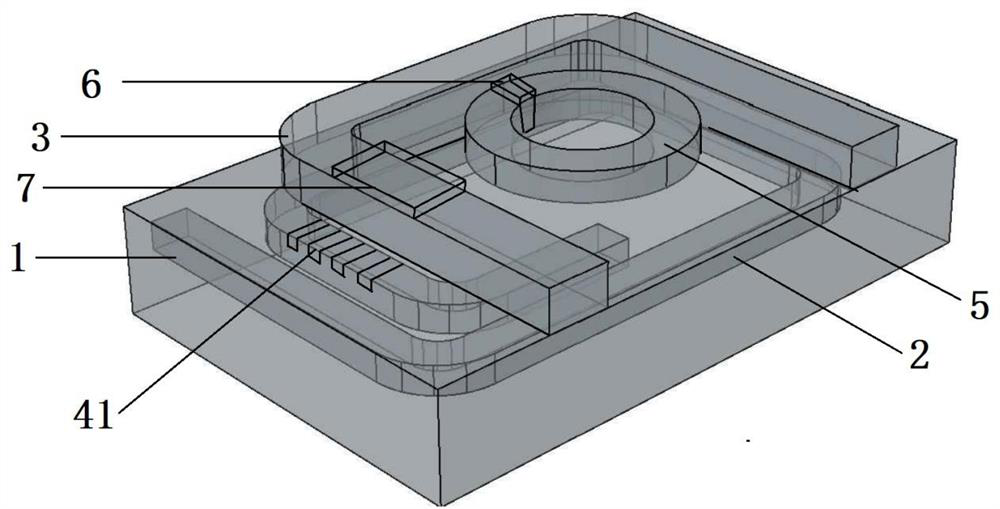

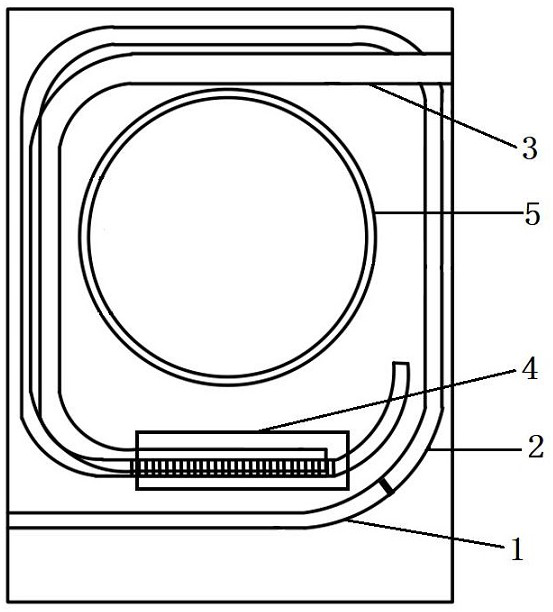

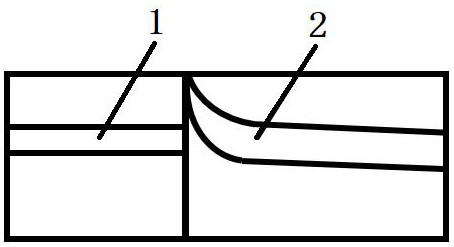

[0033] In the following, the narrow linewidth tunable laser chip and its preparation method and laser of the present invention will be further explained in conjunction with the accompanying drawings:

[0034] The present invention provides a small size and narrow linewidth laser chip based on vertical coupling and micro-ring reflection technology. The active gain waveguide of the laser chip is used to provide signal gain; the lower passive waveguide serves as the expansion cavity of the active gain waveguide. Compress the line width of the output signal; the upper passive waveguide exchanges optical signals with the lower passive waveguide through the vertical coupling technology, extending the cavity length and further compressing the signal line width; the micro-ring reflector is coupled with the upper passive waveguide, on the one hand Play the role of a mirror, on the other hand, it also compresses the line width of the laser; the lower passive waveguide and the upper passive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com