Device and method for purifying butane by tower pressure stable type debutanizer

A debutanizer and fixed-type technology, applied in the field of natural gas processing, can solve the problems of unqualified product quality and easy fluctuation of tower operating pressure, and achieve the effect of rapid control and stabilization of light hydrocarbon quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

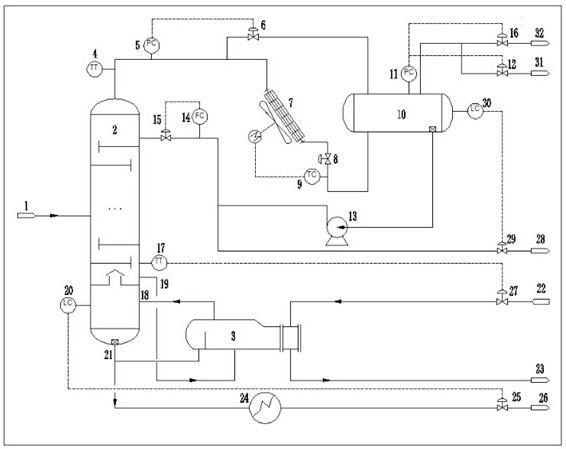

[0048] The first embodiment of the present invention relates to a method for purifying butane in a pressure-stabilized debutanizer, referring to figure 1 , including the following steps:

[0049] S1, transfer C from outside the boundary area 4 + After the mixed hydrocarbon 1 is metered and adjusted, it is introduced into the middle and upper part of the debutanizer 2;

[0050] S2, introducing step S1 into C of debutanizer 2 4 + The mixed hydrocarbon 1 is divided into two phases of gas and liquid in the tower, and its liquid phase descends and contacts with the rising gas phase for mass transfer and heat transfer, the top of the debutanizer 2 discharges the gas phase stream, and the tower bottom discharges the liquid phase stream;

[0051] S3, the temperature of the gas phase stream discharged from the top of the debutanizer 2 is detected, and divided into two streams, the main stream and the secondary stream. ~48°C, all the gas phase is condensed into liquefied gas;

[0...

no. 2 approach

[0061] This embodiment relates to a device for purifying butane in a pressure-stabilized debutanizer, such as figure 1 As shown, it includes at least a debutanizer 2, a slanted top air cooler 7, a reflux tank 10, a reflux pump 16, a reboiler 3 and a bottom cooler 24, and the upper side wall of the debutanizer 2 is provided with The raw material inlet, the top of the debutanizer 2 is provided with a gas phase outlet, and the bottom of the tower is provided with a liquid phase inlet and a liquid phase outlet;

[0062] C 4 + The mixed hydrocarbon 1 enters the debutanizer 2 through the raw material inlet in the upper part of the debutanizer 2, and the gas phase outlet at the top of the debutanizer 2 is connected to the inlet of the inclined-top air cooler 7 through pipeline 1, and the inclined-top air cooler 7 The outlet communicates with the liquid inlet of the reflux tank 10 through pipeline two, and the gas phase outlet on the top of the reflux tank 10 discharges the product ...

no. 3 approach

[0065] On the basis of the second embodiment, further, the reboiler 3 is provided with a reboiler liquid inlet 18, a reboiler liquid outlet 19, a heat transfer oil inlet and a heat transfer oil outlet, and the heat transfer oil of the reboiler 3 The inlet is connected to the high-temperature heat transfer oil 22 through the oil inlet pipeline, and the heat transfer oil outlet of the reboiler 3 is connected to the low-temperature heat transfer oil 23 through the oil outlet pipeline. The towers 2 are connected, and the reboiled liquid inlet 18 is located above the reboiled liquid outlet 19 . The oil inlet pipeline is equipped with a heat transfer oil temperature regulating valve 27 and a tower kettle temperature detector 17. Specifically, one end of the tower kettle temperature detector 17 is connected to the debutanizer 2, and the tower kettle temperature detector 17 The other end is connected with the heat transfer oil temperature regulating valve 27. The tower kettle tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com