Soft, glutinous, comfortable and elastic skin-fitting underwear fabric

An underwear fabric and skin-fitting technology, which is applied in the direction of fabric surface trimming, yarn removal, and floating yarn removal, can solve the problems of fiber fineness, poor hand feel and elasticity, insufficient softness and smoothness, skin-friendly, poor moisture absorption and release performance, etc. , to achieve the effect of plump fluff, increased color layering, and smooth cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

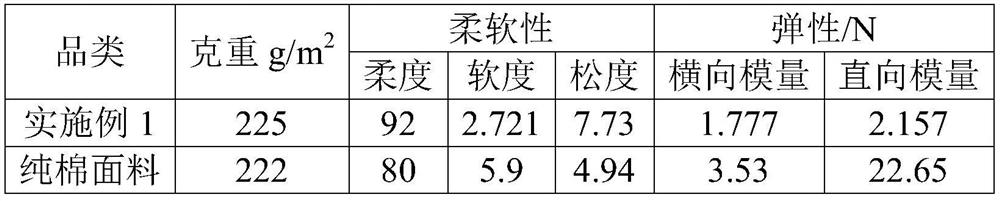

Embodiment 1

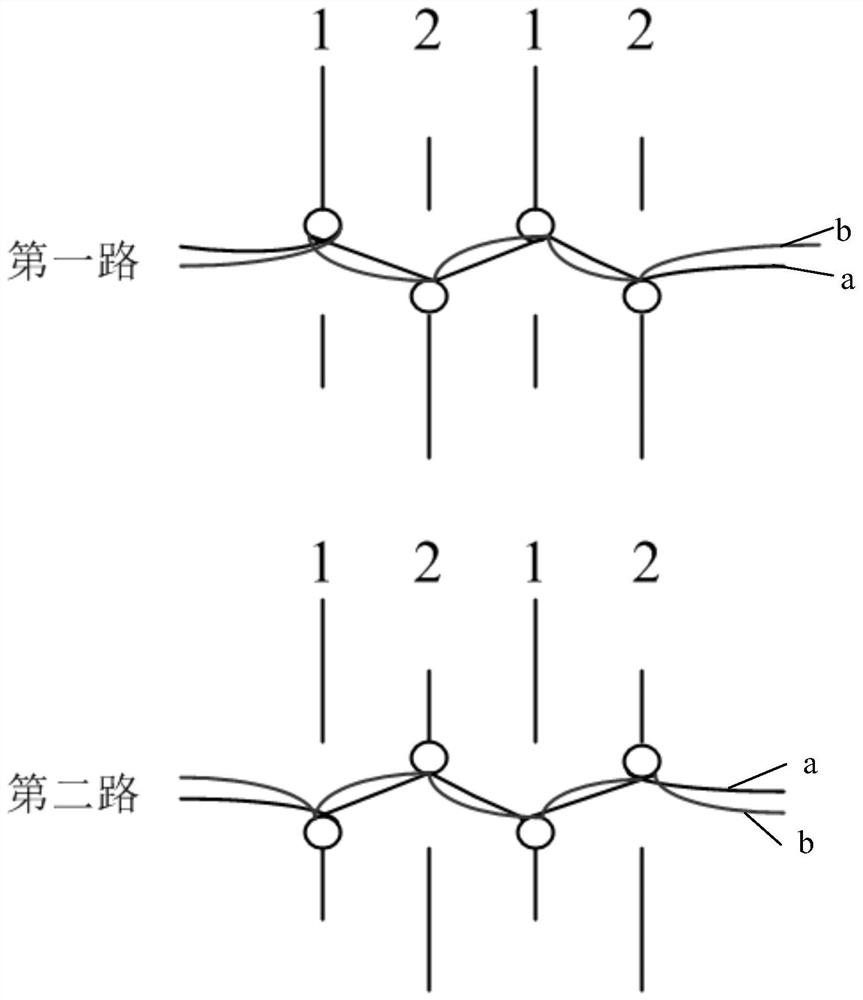

[0028] A kind of soft glutinous and elastic skin-fitting underwear fabric, characterized in that the fabric is a knitted double rib structure, which is woven with spandex and regenerated cellulose fiber Lenzing Modal, and the fineness of Lenzing Modal fiber is 0.9D. The modulus is 200, and the dynamic friction coefficient is 0.2.

[0029] The spinning method of the blended yarn is compact spinning, the yarn is colored spinning, the yarn count is 60S, and the twist coefficient is 330.

[0030] The fabric is woven on a 28-needle and 34-inch double-sided circular knitting machine. When weaving, 25D fusible Lycra spandex yarn is fed into the blended yarn.

[0031] Carry out fleece treatment to described fabric, technological process is setting-fleece-fleece-ironing-shearing, the grammage of finished fabric after treatment is 210g / m 2 .

[0032] The setting process parameters are a temperature of 180°C and a vehicle speed of 20m / min.

[0033] The fleece equipment is four 42-roll...

Embodiment 2

[0037] A kind of soft glutinous and elastic skin-fitting underwear fabric, the fabric is a knitted double rib weave structure, which is woven with spandex and blended yarns, and the blended yarns include 75% regenerated cellulose fibers Lenzing Modal and 25% cotton fiber, cotton fiber length is 33mm, modal fiber fineness is 0.9D, initial modulus is 180, dynamic friction coefficient is 0.2.

[0038] The spinning method of the blended yarn is compact spinning, the yarn is colored spinning, the yarn count is 60S, and the twist coefficient is 330.

[0039] The fabric is woven on a 28-needle and 34-inch double-sided circular machine. When weaving, 25D fusible Lycra spandex yarn is fed into the blended yarn. The blended yarn has a line length of 2.6 mm and a spandex line length of 0.97 mm.

[0040] Carry out fleece treatment to the fabric, the fleece process is finalizing-fleece-fleece-shearing-shearing, and the grammage of the finished fabric after treatment is 220g / m 2 .

[0041...

Embodiment 3

[0046] A kind of soft glutinous and elastic skin-fitting underwear fabric, the fabric is a knitted double rib weave structure, which is woven with spandex and blended yarn, and the blended yarn includes 75% regenerated cellulose fiber Bora viscose in terms of mass fraction , 15% acrylic fiber and 10% cotton fiber, cotton fiber length is 33mm, viscose fiber fineness is 0.8D, initial modulus is 250, dynamic friction coefficient is 0.25, acrylic fiber fineness is Mitsubishi 0.9D expanded acrylic fiber, boiling water shrinkage 17%-18%.

[0047] The spinning method of the blended yarn is siro spinning, the yarn is white yarn, the yarn count is 50S, and the twist coefficient is 300.

[0048] The fabric is woven on a 28-needle and 34-inch double-sided circular machine. When weaving, 20D fusible Lycra spandex yarn is fed into the blended yarn. The blended yarn has a line length of 2.7 mm and a spandex line length of 1.05 mm.

[0049] Carry out fleece treatment to described fabric, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com