Flying-noxious-insect-repellent product and method for repelling flying noxious insects

A pest repellent and product technology, applied in animal repellents, botanical equipment and methods, chemicals for biological control, etc. The effect of excellent volatile performance and high usefulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] Examples of solvents used in the preparation of flying pest repellent products include lower alcohols such as water, ethanol, and isopropanol; ketone-based solvents, ester-based solvents, and hydrocarbon-based solvents such as normal alkanes and isoalkanes. These solvents may be used alone or in any combination. Surfactants include, for example, polyoxyethylene hydrogenated castor oil, polyoxyethylene higher alkyl ethers (polyoxyethylene lauryl ether, polyoxyethylene oleyl ether, etc.), polyoxyethylene alkylphenyl ethers, polyoxyethylene Higher fatty acid esters, polyoxyethylene sorbitan fatty acid esters, polyoxyethylene fatty acid glycerides, polyoxyethylene polyoxypropylene alkyl ethers and other non-ionic surfactants; laurylamine oxide, stearylamine oxide , lauryl amidopropyl dimethylamine oxide and other advanced alkylamine oxide-based surfactants, etc. These surfactants may be used alone or in any combination.

[0079] By adding the above-mentioned flying pest r...

Embodiment 1

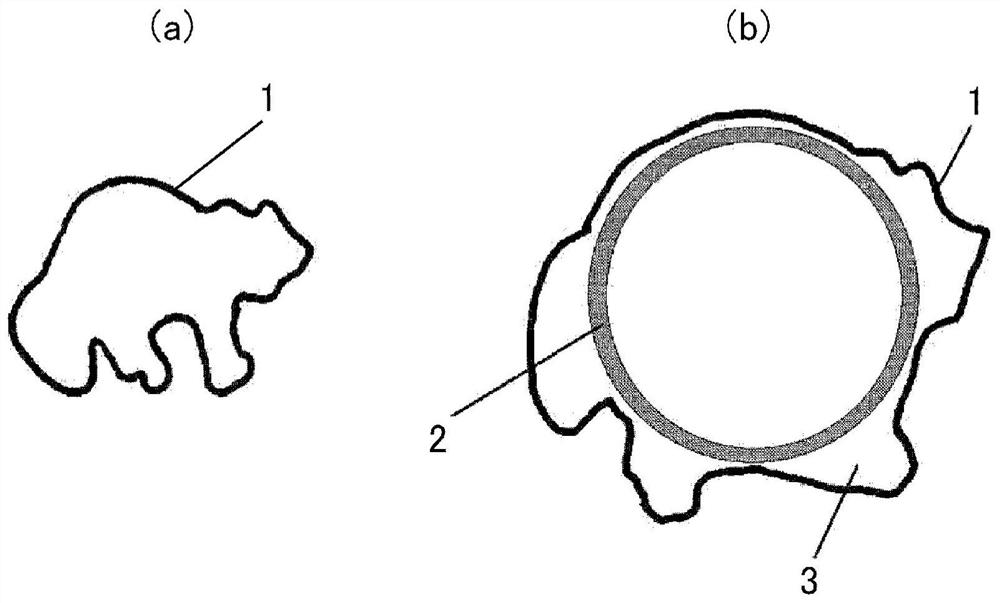

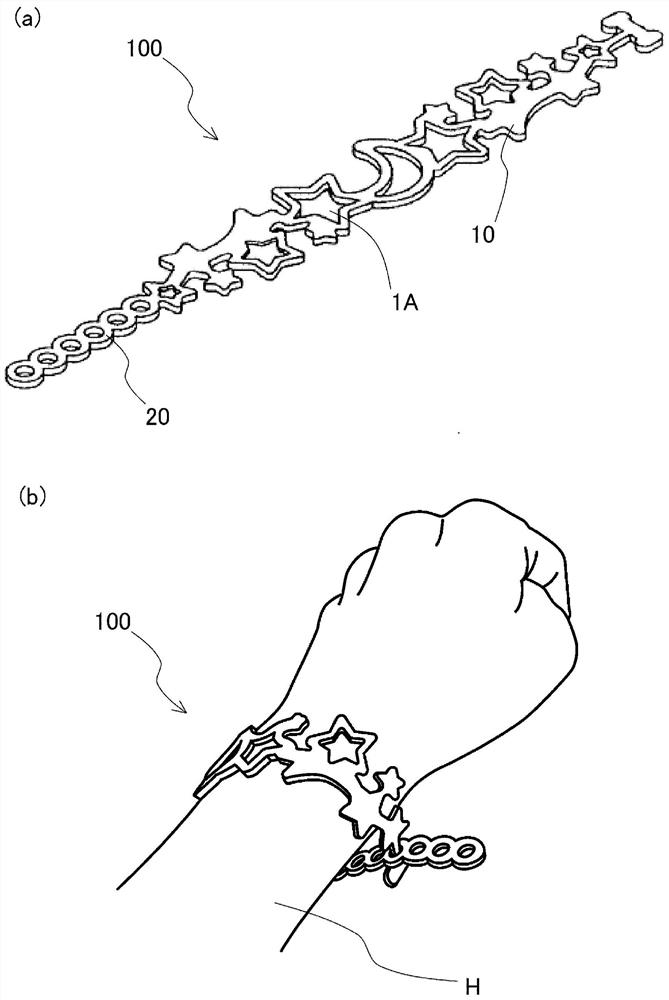

[0096] As a two-component addition type liquid silicone rubber composition, silicone rubber composition 1 and 2 were prepared according to the following recipe, the prepared silicone rubber composition 1 and 2 were mixed at room temperature, and the injection molding machine was used to It is cured at 140°C and formed into a rope ring imitating animal characters (wire diameter: about 2mm, weight: 1.6g, hardness: 32 degrees). After molding, it was placed in an oven, and post-cured at 210° C. for 5 hours to obtain a silicone rubber molded body.

[0097] ・Silicone rubber composition 1 liquid

[0098] (A) Component: 63% by mass of methylvinylpolysiloxane whose ends of the molecular chain are terminated by dimethylvinylsiloxane groups

[0099] (C) Component: 0.05% by mass of a complex of chloroplatinic acid and 1,3-divinyltetramethyldisiloxane

[0100] (D) Component: Siloxane-modified silica (using HMDS as a surface treatment agent) 20% by mass

[0101] Extender filler: microsil...

Embodiment 2~10、 comparative example 1~5

[0124] Except that the components (A) and (D) of the addition-type liquid silicone rubber composition were changed to the compositions shown in Table 1, according to Example 1, the cured product of the addition-type liquid silicone rubber composition was molded into a rope shape The rubber molded body was made to absorb the flying pest repelling fragrance composition of the composition shown in Table 2 to obtain the flying pest repelling product of the present invention (Examples 2-10). It should be noted that in Table 1, "A-1" refers to dimethyl polysiloxane whose ends of the molecular chain are terminated by dimethylvinylsiloxane groups, and "A-2" refers to the two ends of the molecular chain Methyl vinyl polysiloxane terminated by trimethylsiloxy group, "A-3" is methyl vinyl polysiloxane terminated by dimethyl vinyl siloxane at both ends of the molecular chain. In addition, "siloxane-modified silica P" is siloxane-modified silica surface-treated with HMDS, and "siloxane-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com