Nickel disulfide material with hollow micro-nano structure, preparation method of nickel disulfide material, aluminum ion battery positive electrode and aluminum ion battery

An aluminum ion battery, micro-nano structure technology, applied in nickel sulfide, battery electrodes, secondary batteries and other directions, can solve the problems of lack of electrode structure, poor battery cycle performance, lack of capacity and long-term stability of materials, etc., to achieve the preparation process Simple, stable cycle performance, non-denaturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a hollow micro-nano structure nickel disulfide material, comprising the following steps:

[0048] 1) Add 1.5g sodium thiosulfate to 150mL deionized water, stir and mix evenly, then add 0.25g sodium lauryl sulfate, stir and mix until uniform, then add 1mL concentrated hydrochloric acid and stir evenly at 25°C for 3 hours, then add The obtained product filter paper was filtered and washed 30 times, and after washing, it was placed in an oven at 30° C. and dried for 5 hours to obtain nano-sulfur particles;

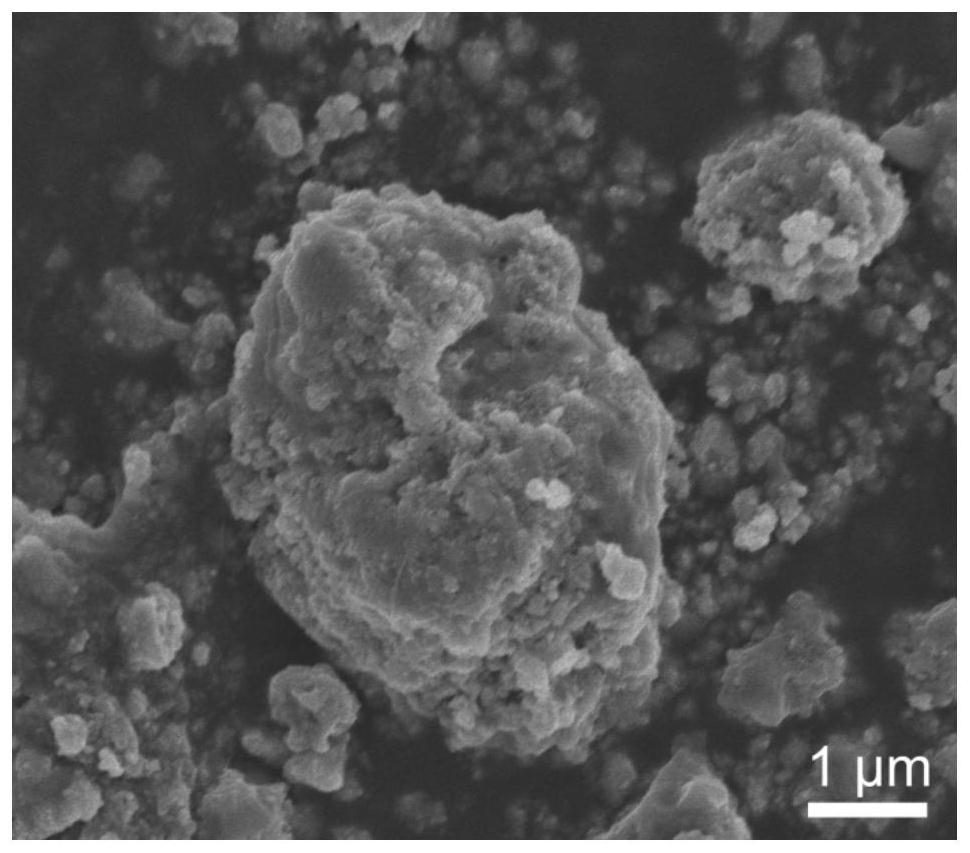

[0049] 2) Magnetically stir 0.08g of nickel nitrate, 0.05g of urea, and 20mL of deionized water evenly, then add 0.1g of nano-sulfur particles obtained in step 1) to the mixed solution, sonicate until dispersed, and transfer the mixed suspension to In a polytetrafluoroethylene liner, react in an oven at 70°C for 300min. After the reaction, cool to room temperature, wash twice by centrifugation, and dry at 55°C for 12h to obtain sulfur particles / n...

Embodiment 2

[0052] A preparation method of hollow micro-nano structure nickel disulfide, comprising the following steps:

[0053] 1) Add 1.75g sodium thiosulfate to 200mL deionized water, stir and mix evenly, then add 0.37g sodium lauryl sulfate, stir and mix until uniform, then add 1mL concentrated hydrochloric acid and stir evenly at 35°C for 1.5h, then Filter and wash the obtained product filter paper 20 times, put it into an oven at 35°C after washing, and dry it for 5 hours to obtain nano-sulfur particles;

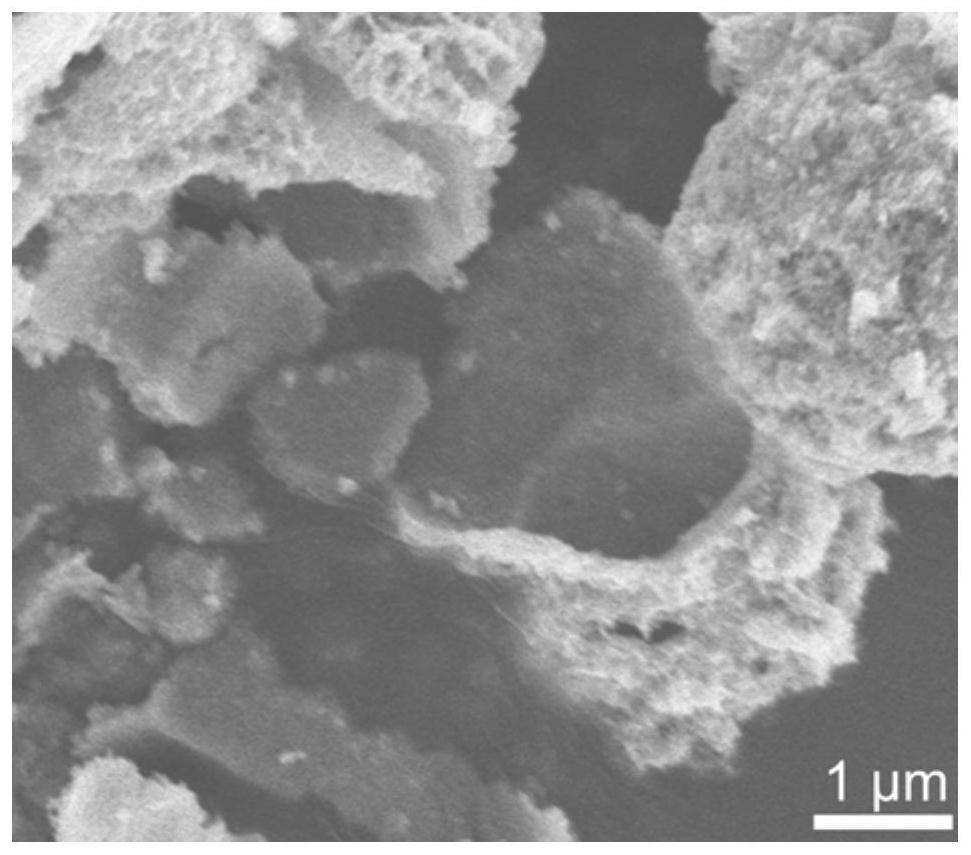

[0054] 2) Magnetically stir 0.12g of nickel nitrate, 0.1g of urea, and 25mL of deionized water evenly, then add 0.12g of nano-sulfur particles obtained in step 1) to the mixed solution, sonicate until dispersed, and transfer the mixed suspension to In a polytetrafluoroethylene liner, react in an oven at 85°C for 320min. After the reaction is completed, cool to room temperature, centrifuge and wash twice, and dry at 75°C for 12h to obtain sulfur particles / nickel oxyhydroxide com...

Embodiment 3

[0057] A preparation method of hollow micro-nano structure nickel disulfide, comprising the following steps:

[0058] 1) Add 1.85g sodium thiosulfate to 300mL deionized water, stir and mix evenly, then add 0.47g sodium lauryl sulfate, stir and mix until uniform, then add 1.5mL concentrated hydrochloric acid and stir evenly at 30°C for 2h, then Filter and wash the obtained product filter paper 20 times, put it into an oven at 45°C after washing, and dry it for 6 hours to obtain nano-sulfur particles;

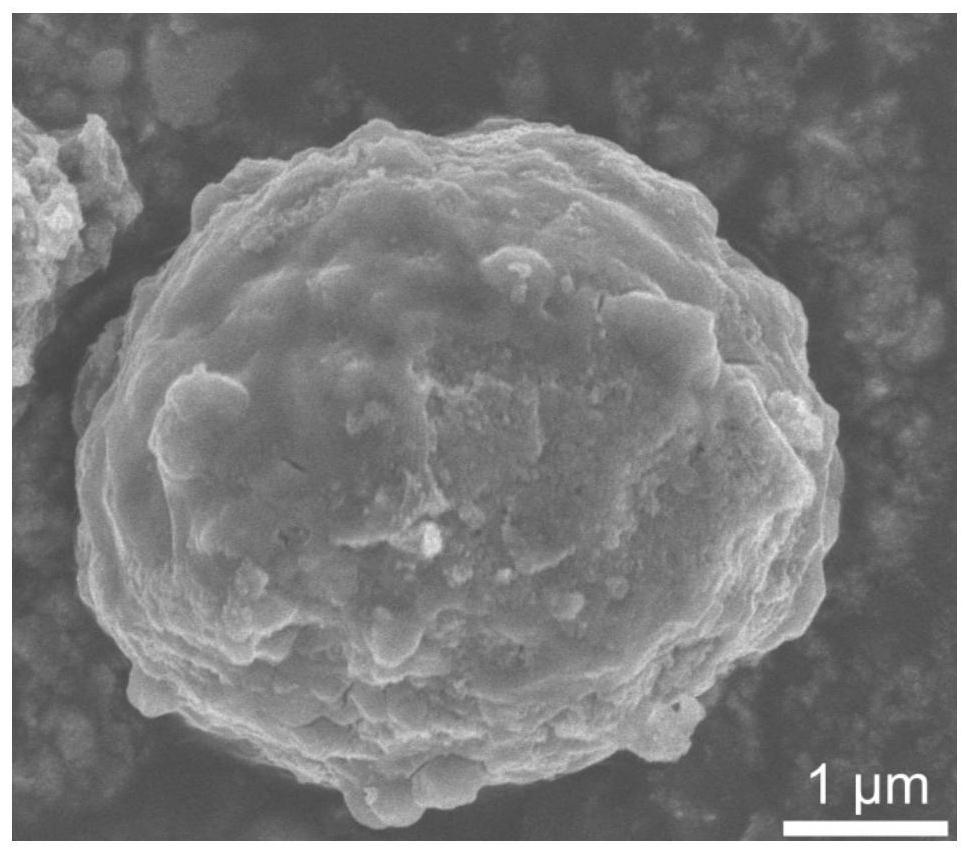

[0059] 2) Magnetically stir 0.12g of nickel nitrate, 0.08g of urea, and 25mL of deionized water evenly, then add 0.12g of nano-sulfur particles obtained in step 1) to the mixed solution, sonicate until dispersed, and transfer the mixed suspension to In a polytetrafluoroethylene liner, react in an oven at 95°C for 320min. After the reaction is completed, cool to room temperature, centrifuge and wash twice, and dry at 75°C for 12h to obtain sulfur particles / nickel oxyhydroxide comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com