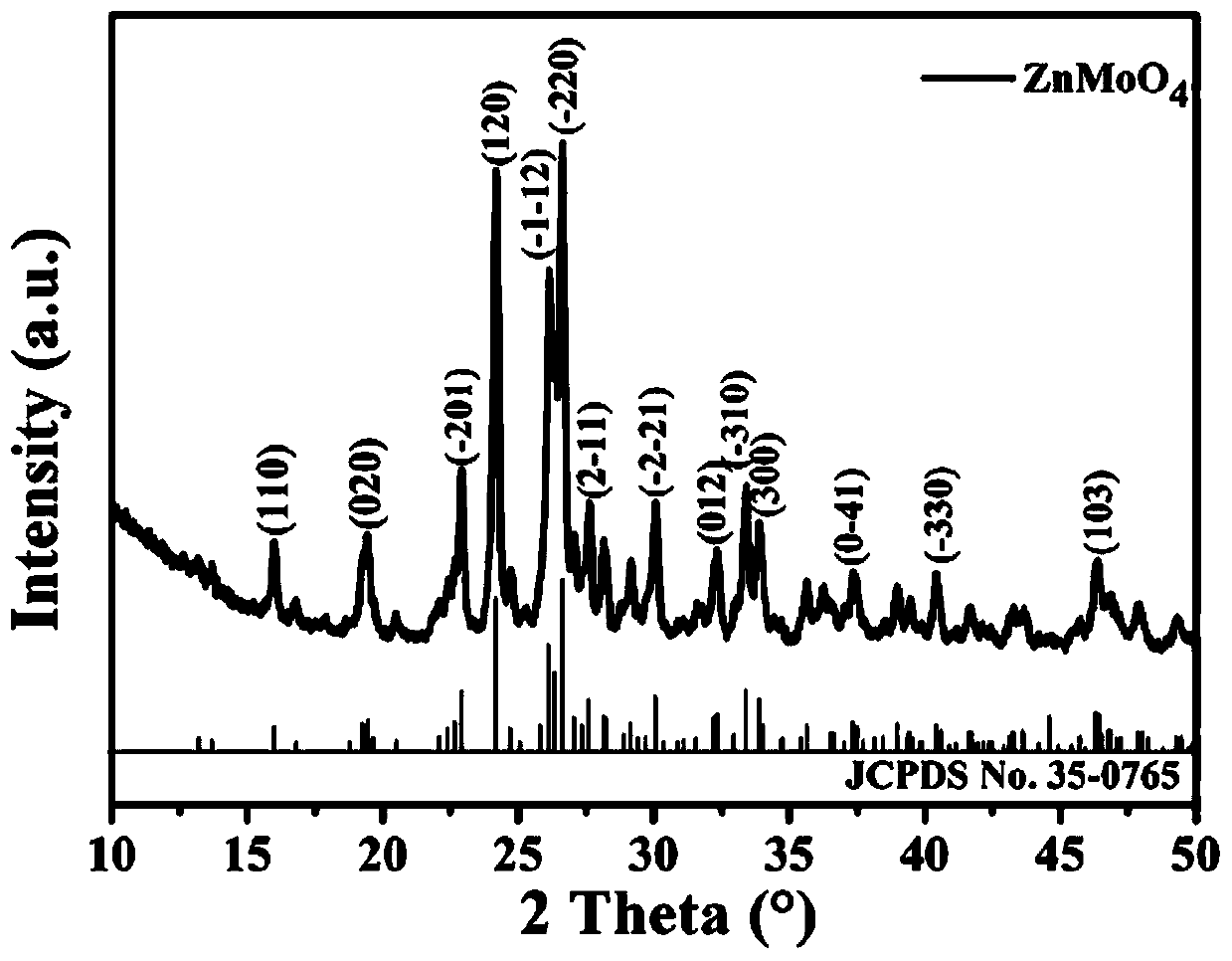

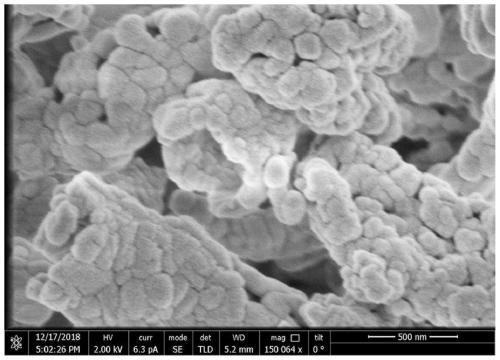

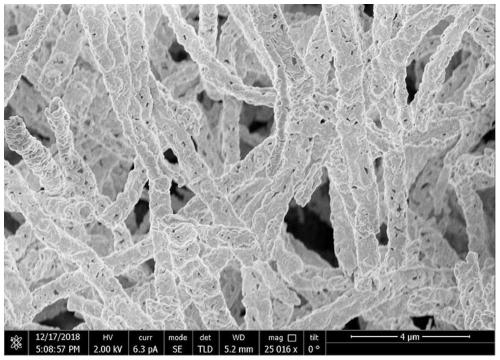

Zinc molybdate nanotube and preparation method and application thereof

A technology of zinc molybdate and nanotubes, which is applied in nanotechnology, chemical instruments and methods, molybdenum compounds, etc., can solve the problems of cumbersome experimental process, large consumption of experimental conditions, and battery capacity attenuation, so as to alleviate excessive volume expansion, Effects of abundant active sites, enhanced electrical conductivity, and ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for zinc molybdate nanotubes, comprising the following steps:

[0040] 1) Weigh 0.2082g of zinc nitrate, 0.1236g of ammonium molybdate and 0.8g of citric acid respectively, and add them into 4mL of deionized water to form a uniform inorganic salt solution.

[0041] 2) Weigh 1 g of PVP K130, dissolve it in 9 g of ethanol, and prepare a PVP solution with a mass concentration of 10%.

[0042] 3) Mix the inorganic salt solution and the PVP solution at a volume ratio of 2:10, and form a uniform spinning solution after stirring for 12 hours.

[0043] 4) Electrospinning was performed using an electrospinning device with a voltage of 18kV and a syringe pump at a speed of 1.5mL / h. Aluminum foil was used as a receiver with a receiving distance of 10cm. The ambient temperature was 30°C and the humidity was 28%.

[0044] 5) After the electrospinning, put the obtained fiber membrane into a tube furnace for calcination under the air atmosphere, the heating rate ...

Embodiment 2

[0047] A preparation method for zinc molybdate nanotubes, comprising the following steps:

[0048] 1) Weigh 0.2777g of zinc nitrate, 0.2258g of sodium molybdate, and 1g of citric acid into 3mL of deionized water to form a uniform inorganic salt solution.

[0049] 2) Weigh 1 g of PVP K90, dissolve it in 9 g of ethanol, and prepare a PVP solution with a mass concentration of 10%.

[0050] 3) Mix the inorganic salt solution and the PVP solution at a volume ratio of 1:10, and stir for 24 hours to form a uniform spinning solution.

[0051] 4) Electrospinning was performed using an electrospinning device with a voltage of 18kV and a syringe pump at a speed of 1.5mL / h. Aluminum foil was used as a receiver with a receiving distance of 10cm. The ambient temperature was 30°C and the humidity was 28%.

[0052] 5) After the electrospinning, put the obtained fiber membrane into a tube furnace for calcination under the air atmosphere, the heating rate is 2°C / min, the calcination temperatur...

Embodiment 3

[0056] A preparation method for zinc molybdate nanotubes, comprising the following steps:

[0057] 1) Weigh 0.4165g of zinc nitrate, 0.3825g of molybdenum chloride, and 1g of citric acid into 5mL of deionized water to form a uniform inorganic salt solution.

[0058] 2) Weigh 2g of PVP K130, dissolve it in 11.3g of ethanol, and prepare a PVP solution with a mass concentration of 15%.

[0059] 3) Mix the inorganic salt solution and the PVP solution at a volume ratio of 2:10, and stir for 24 hours to form a uniform spinning solution.

[0060] 4) Electrospinning was performed using an electrospinning device with a voltage of 15kV and a syringe pump at a speed of 1mL / h. Aluminum foil was used as a receiver with a receiving distance of 10cm. The ambient temperature was 35°C and the humidity was 25%.

[0061] 5) After the electrospinning, the obtained fiber membrane was put into a tube furnace for calcination under the air atmosphere, the heating rate was 2°C / min, the calcination te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com