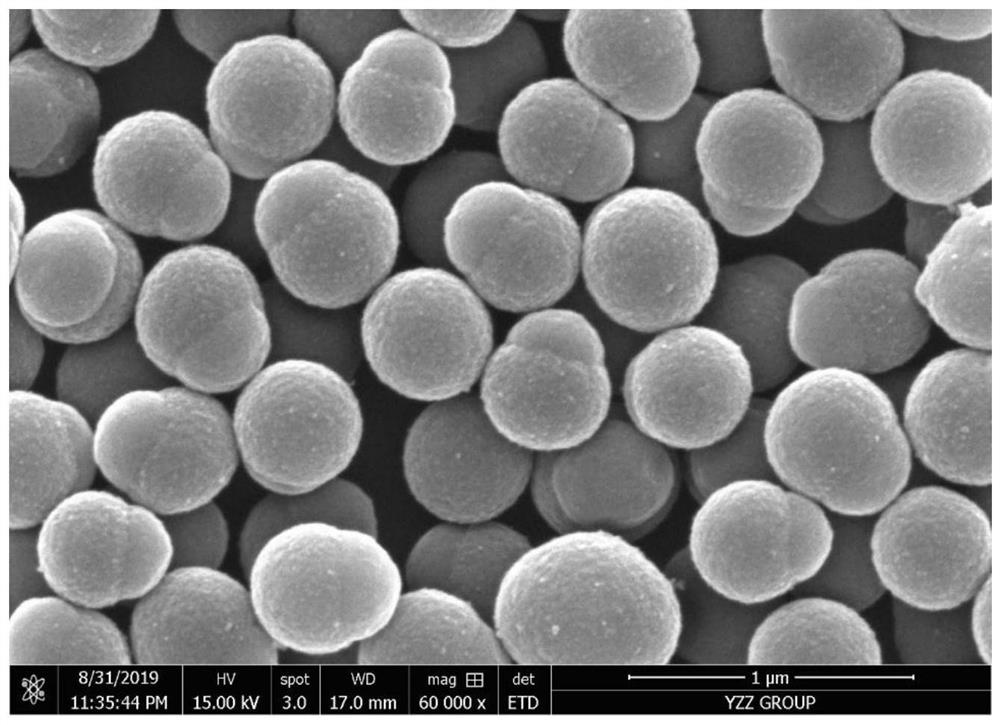

Snowman-shaped Janus particles and preparation method thereof

A particle and snowman technology, applied in the field of snowman-shaped Janus particles and its preparation, can solve the problems of poor comprehensive performance such as weather resistance, water resistance, oil resistance, strength, etc., and achieve the effects of narrow particle size distribution, simple operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]The present invention also provides a kind of preparation method of snowman shape Janus particle, comprises the following steps:

[0038] S1, preparing polybutylacrylate / polyethylene glycol dimethacrylate (PBA / PEGDMA) seed emulsion;

[0039] S2. Heat the PBA / PEGDMA seed emulsion to 65-75°C, and slowly add the silane coupling agent monomer emulsion to the PBA / PEGDMA seed emulsion at a constant temperature and stirring speed of 100-800r / min, and react at a constant temperature for 18- 24h;

[0040] S3. After the constant temperature reaction is finished, centrifuge to obtain the product, and first use ethanol to wash centrifugally, then after centrifugally wash with water, freeze-dry to obtain organic / inorganic composite snowman-shaped Janus particles, the hydrophilic end of organic / inorganic composite snowman-shaped Janus particles is two Silicon oxide with hydrophobic ends ethylene glycol dimethacrylate / polybutyl acrylate.

[0041] Specifically, in the above S1, the st...

Embodiment 1

[0062] The present embodiment provides a kind of snowman shape Janus particle, and the preparation method is as follows:

[0063] 240 g of secondary water was added to 20 g of linear polybutylacrylate seed emulsion with a solid content of 37.5 wt.%, and ultrasonically dispersed to obtain a uniform seed emulsion. 4.5g crosslinking agent ethylene glycol dimethacrylate (EGDMA), 0.045g oily initiator azobisisobutyronitrile (AIBN), 0.072g surfactant sodium dodecyl sulfate (SDS) and 30g secondary Water, after mixing, ultrasonically emulsify to obtain a monomer emulsion. Add the homogeneously dispersed monomer emulsion into the seed emulsion and ultrasonically disperse it uniformly, stir and swell at 25°C and 300r / min for 8h, then raise the temperature to 70°C, and react at constant temperature for 12h to obtain EGDMA cross-linked PBA / PEGDMA seed emulsion with good solvent resistance.

[0064] Take 49.2 g of the above-mentioned cross-linked PBA / PEGDMA hollow emulsion as seed emuls...

Embodiment 2

[0067] The present embodiment provides a kind of snowman shape Janus particle, and the preparation method is as follows:

[0068]240 g of secondary water was added to 20 g of linear polybutylacrylate seed emulsion with a solid content of 37.5 wt.%, and ultrasonically dispersed to obtain a uniform seed emulsion. 4.5g crosslinking agent ethylene glycol dimethacrylate (EGDMA), 0.045g oily initiator azobisisobutyronitrile (AIBN), 0.072g surfactant sodium dodecyl sulfate (SDS) and 30g secondary Water, after mixing, ultrasonically emulsify to obtain a monomer emulsion. Add the homogeneously dispersed monomer emulsion into the seed emulsion and ultrasonically disperse it uniformly, stir and swell at 25°C and 300r / min for 8h, then raise the temperature to 70°C, and react at constant temperature for 12h to obtain EGDMA cross-linked PBA / PEGDMA seed emulsion with good solvent resistance.

[0069] Take 49.2 g of the above-mentioned cross-linked PBA / PEGDMA hollow emulsion as seed emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com