Nano-foam lifting liquid-draining gas production rod and preparation method and application

A liquid drainage gas recovery and foam lifting technology, which is applied in chemical instruments and methods, mining fluids, earth drilling and production, etc., can solve the problems of limited application range, low efficiency, water flooding and shutdown of gas wells, etc. , to achieve excellent resistance to condensate oil and methanol, enhance ultimate recovery, and restore gas well productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

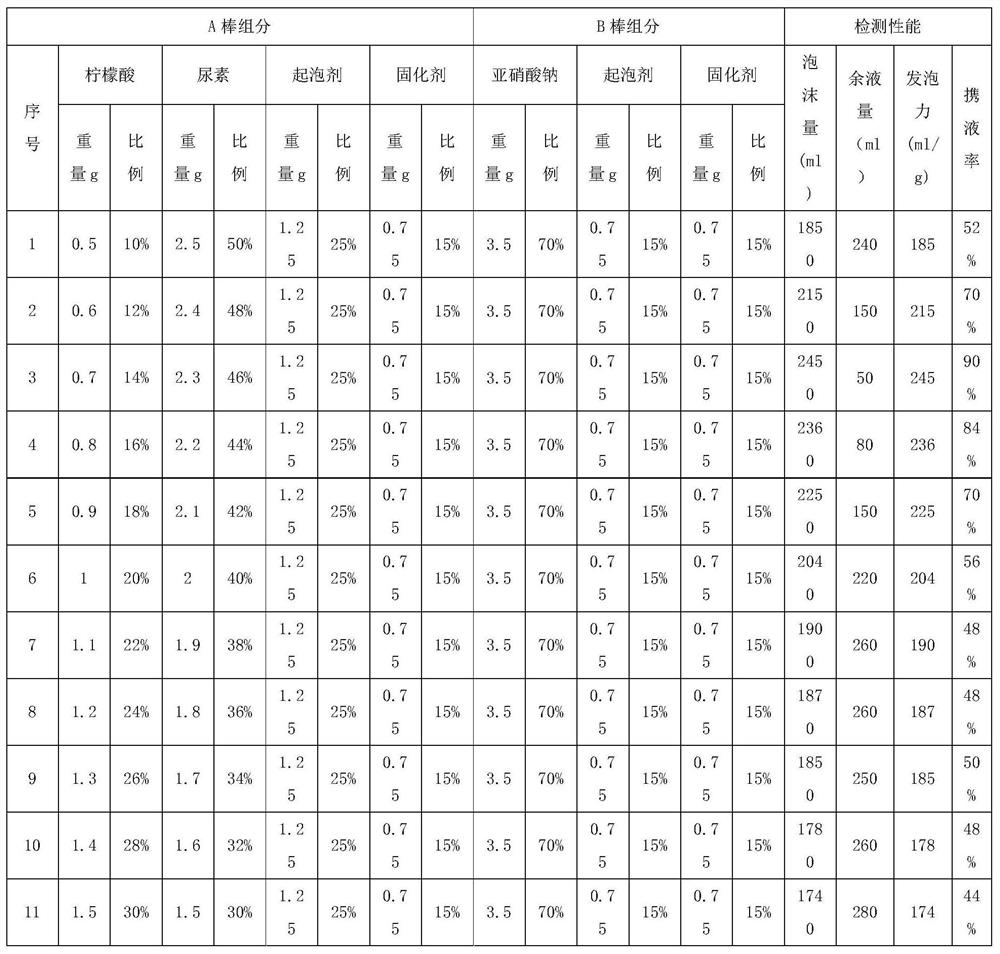

Examples

Embodiment 1

[0030] This embodiment provides a nano-foam lifting liquid drainage gas sampling rod, including a gas well foam lifting liquid drainage gas sampling rod A rod and a gas well foam lifting liquid drainage gas sampling rod B rod. Air stick A stick includes raw material components with the following mass ratio: 25-35 parts of surfactant sodium lauryl sulfate, 0.1-0.3 parts of foam stabilizer sodium perfluorononenyloxybenzenesulfonate, 15-25 parts Parts of curing agent OP-25, 10-15 parts of citric acid and 25-50 parts of urea; specifically, the surfactant sodium lauryl sulfate can be but not limited to 25 parts, 30 parts or 35 parts etc. etc., the specific amount is not limited, and it can be kept within the scope required by this embodiment according to the actual situation; the foam stabilizer sodium perfluorononenyloxybenzene sulfonate can be but not limited to 0.1, 0.2 part or 0.3 part, etc., the specific amount is not limited, and it can be kept within the scope required by th...

Embodiment 2

[0037] This embodiment is a further improvement made on the basis of Embodiment 1. The specific differences between this embodiment and Embodiment 1 are:

[0038] In this embodiment, it is further preferred that the gas well foam lifting liquid drainage gas extraction rod A rod specifically includes the following raw material components in mass proportion: 30 parts of surfactant sodium lauryl sulfate, 0.2 part of foam stabilizing agent Agent perfluorononenyloxybenzene sulfonate sodium, 20 parts of curing agent OP-25, 12 parts of citric acid and 37 parts of urea.

Embodiment 3

[0040] This embodiment is a further improvement made on the basis of Embodiment 1. The specific differences between this embodiment and Embodiment 1 are:

[0041] In this embodiment, it is further preferred that the gas well foam lifting liquid drainage gas extraction rod A rod specifically includes the following raw material components in mass proportion: 35 parts of surfactant sodium lauryl sulfate, 0.3 part of foam stabilizing agent Agent perfluorononenyloxybenzene sulfonate sodium, 25 parts of curing agent OP-25, 15 parts of citric acid and 50 parts of urea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com