Preparation technology of blue luminous titanium disulfide nanocrystals

A technology of titanium disulfide and nanocrystals, applied in nanotechnology, titanium sulfide, inorganic chemistry, etc., can solve problems such as poor dispersion, uneven size, and high cost, and achieve performance breakthroughs, uniform size, and low cost.

Inactive Publication Date: 2019-08-13

YUNNAN NORMAL UNIV +2

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Nevertheless, strict control of TiS 2 Nanocrystalline thickness and lateral dimensions to achieve TiS 2 The controllable preparation of nanocrystals still faces many difficulties

[0004] As far as the traditional preparation methods are concerned, the preparation of nanocrystals by molecular beam epitaxy, chemical vapor deposition, magnetron sputtering and other equipment has problems such as high cost, serious particle agglomeration, poor dispersion, large particle size, and uneven size. In the case of material properties, it is particularly important to find a preparation technology that is easy to operate, low in cost, and easy to implement to expand the application of nanomaterials in multiple fields.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Embodiment 1: Weigh 0.5 gram of TiS 2 Put the solid powder in an agate mortar and grind it fully for 1.5 hours, transfer the ground powder to a beaker, add 50ml of N-methylpyrrolidone (NMP) solvent to it and mix well, and place the obtained mixture in a cell disruptor Broken for 4 hours. Take an appropriate amount of solution and centrifuge, and take the supernatant after centrifugation to obtain TiS 2 Nanocrystalline.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

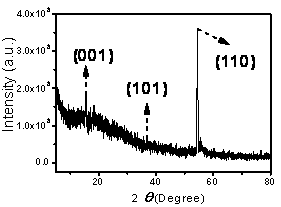

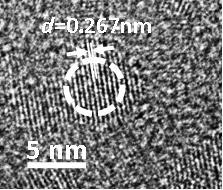

The invention relates to a preparation technology of blue luminous titanium disulfide nanocrystals. A physical and chemical combination method is used for preparing TiS2 nanocrystals. The aim of physical grinding is to introduce line defects (dislocations), so that the crystals have tensile stress, the band gap can be increased, the size is smaller and more controllable, and convenience is provided for formation of the nanocrystals. The TiS2 nanocrystals prepared through a cell disruption instrument show good dispersity and have high fluorescence. The preparation technology of the blue luminous titanium disulfide nanocrystals is characterized in that the experiment method is easy and convenient to implement, and the product with good dispersity and a small and even size can be prepared. Itcan be known through representation of a transmission electron microscope that the intervals of lattice strips of the TiS2 nanocrystals are 0.267 nanometer, and the average particle diameter is 3.1 nanometers. In addition, the nanocrystals give out blue fluorescence under irradiation of an ultraviolet lamp of 365 nanometers and are expected to be applied to the fields such as gene identification,biological imaging, photoelectron imaging and device manufacturing.

Description

technical field [0001] The invention relates to a preparation technology of blue luminous titanium disulfide nanocrystals, in particular to changing the size of titanium disulfide and adjusting the band gap of titanium disulfide to achieve the effect of blue luminescence. Background technique [0002] In recent years, two-dimensional transition metal dichalcogenides (2D-TMDs) have become a current research hotspot due to their unique physical and chemical properties. Titanium disulfide (TiS 2 ) has a layered structure similar to graphene, and the layers are combined by weak van der Waals force, so it is known as "Inorganic Graphene". Compared to the zero-gap nature of graphene, many layered TiS 2 There is a direct band gap, so it produces a series of novel and unique optical, electrical, magnetic, mechanical, chemical and other properties, which has become a hot spot in the field of materials research. [0003] Although there are currently some 2 Research reports on the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G23/00B82Y40/00

CPCB82Y40/00C01G23/007C01P2002/72C01P2002/84C01P2004/04C01P2004/64C01P2006/60

Inventor 李学铭唐利斌周亮亮潘峰杨艳波鲁朝宇梁晶

Owner YUNNAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com