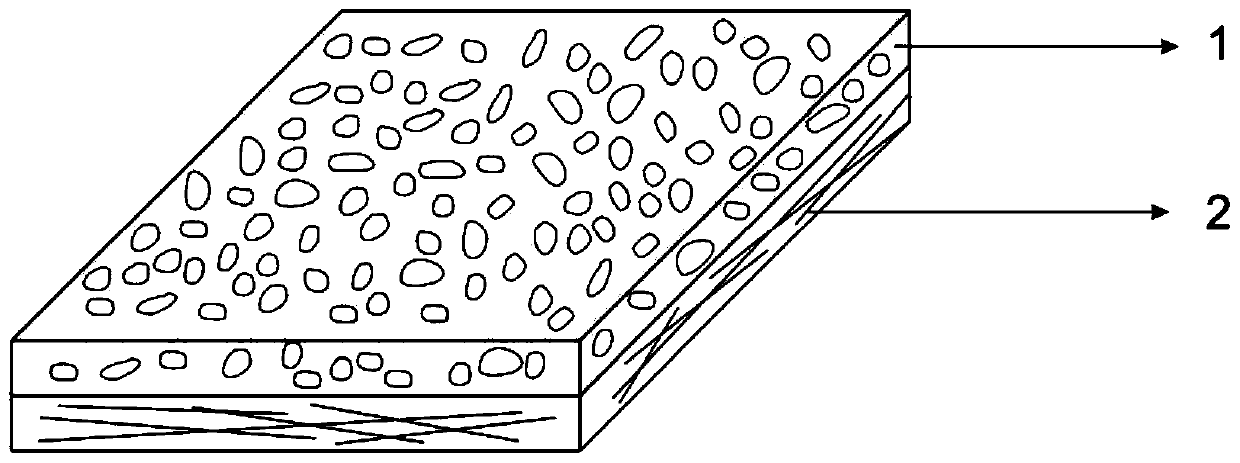

An antibacterial cation-modified absorbable dura mater repair material and its preparation method and application

A repair material and a cationic technology, applied in the field of antibacterial cationic modified absorbable artificial dura mater and its preparation, can solve the problem that long-term bacteriostasis cannot be achieved, and no polycaprolactone electrospun fiber membrane scaffold material is involved in bacteriostasis characteristics and other issues, to achieve good application prospects, easy control of product quality, and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Dissolve polylactic acid-caprolactone copolymer (PLCL) with a weight average molecular weight of 300,000 in hexafluoroisopropanol at a concentration of 0.08 g / ml, and form a uniform and stable solution after stirring at room temperature. The solution is then put into a syringe, and the needle of the syringe is connected to a high-voltage power supply. The solution supply flow rate was controlled at 1 ml / hour, the applied voltage was 15 kV, the distance between the high-voltage end and the ground end was 15 cm, and a rotating drum with a diameter of 8 cm was used as a collection device at a speed of 100 rpm. After spinning the PLCL solution, a nanofiber film with a thickness of about 0.2 mm can be collected.

[0054] Place the PLCL nanofiber membrane in a low-temperature plasma reaction chamber, close the reaction chamber and evacuate to 5Pa, then pass in helium gas, and adjust the working pressure to 20Pa. After the airflow is stable, turn on the radio frequency power ...

Embodiment 2

[0058] Dissolve poly-L-lactic acid (PLLA) with a weight average molecular weight of 300,000 in chloroform at a concentration of 0.1 g / ml, and form a uniform and stable solution after stirring at room temperature. The solution is then put into a syringe, and the needle of the syringe is connected to a high-voltage power supply. The solution supply flow rate was controlled at 1.5 ml / hour, the applied voltage was 17.5 kV, the distance between the high-voltage end and the ground end was 12.5 cm, and a rotating drum with a diameter of 8 cm was used as a collection device at a speed of 100 rpm. After spinning the PLLA solution, a nanofiber film with a thickness of about 0.25 mm can be collected.

[0059] At 4°C, the PLLA nanofiber membrane was soaked in a 0.1M sodium hydroxide solution for 15 minutes, and then the fiber membrane was taken out and washed with a large amount of deionized water. At 4 °C, the carboxylated PLLA nanofiber membrane was soaked in a mixed solution containin...

Embodiment 3

[0062] Polylactic acid-glycolic acid copolymer (PLGA) with a weight average molecular weight of 250,000 was dissolved in acetone at a concentration of 0.2 g / ml, and a uniform and stable solution was formed after stirring at room temperature. The solution is then put into a syringe, and the needle of the syringe is connected to a high-voltage power supply. The solution supply flow rate was controlled at 2 ml / hour, the applied voltage was 20 kV, the distance between the high voltage end and the ground end was 20 cm, and a rotating drum with a diameter of 8 cm was used as the collection device at a speed of 100 rpm. After spinning the PLGA solution, a nanofiber film with a thickness of about 0.15 mm can be collected.

[0063] Soak the PLGA nanofiber membrane in a hydrogen peroxide solution with a volume fraction of 10%, and then place it under a UV lamp with a wavelength of 350nm and a power of 40W at a distance of 10cm. After reacting for 30 minutes, take it out and wash it with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com